The Advantages of Bronze Sleeve Bushings in Automotive Applications

Superior Durability and Wear Resistance

Bronze sleeve bushings exhibit remarkable durability and wear resistance, attributes that are paramount in the automotive industry. The intrinsic properties of bronze alloys, such as their high tensile strength and hardness, contribute to the longevity of these components. In the demanding environment of a vehicle's engine and chassis, where constant motion and heavy loads are the norm, bronze sleeve bushings maintain their structural integrity and performance over extended periods.

The wear-resistant nature of bronze sleeve bushings is particularly beneficial in applications involving repetitive motion or continuous contact between surfaces. This characteristic significantly reduces the frequency of part replacements, thereby minimizing vehicle downtime and maintenance costs. Moreover, the wear resistance of bronze bushings helps preserve the dimensional accuracy of moving parts, ensuring consistent performance throughout the vehicle's lifespan.

Excellent Thermal Conductivity

One of the standout features of bronze sleeve bushings is their excellent thermal conductivity. This property is invaluable in automotive applications where heat dissipation is crucial for optimal performance and longevity of components. The ability of bronze to efficiently conduct heat away from friction points helps prevent overheating and thermal damage to surrounding parts.

In engine applications, where temperatures can fluctuate dramatically, the thermal conductivity of bronze sleeve bushings aids in maintaining stable operating conditions. This temperature regulation contributes to more consistent engine performance and helps extend the life of both the bushings and the components they support. The thermal properties of bronze also make these bushings suitable for use in a wide range of climatic conditions, from extreme cold to high heat environments.

Self-Lubricating Properties

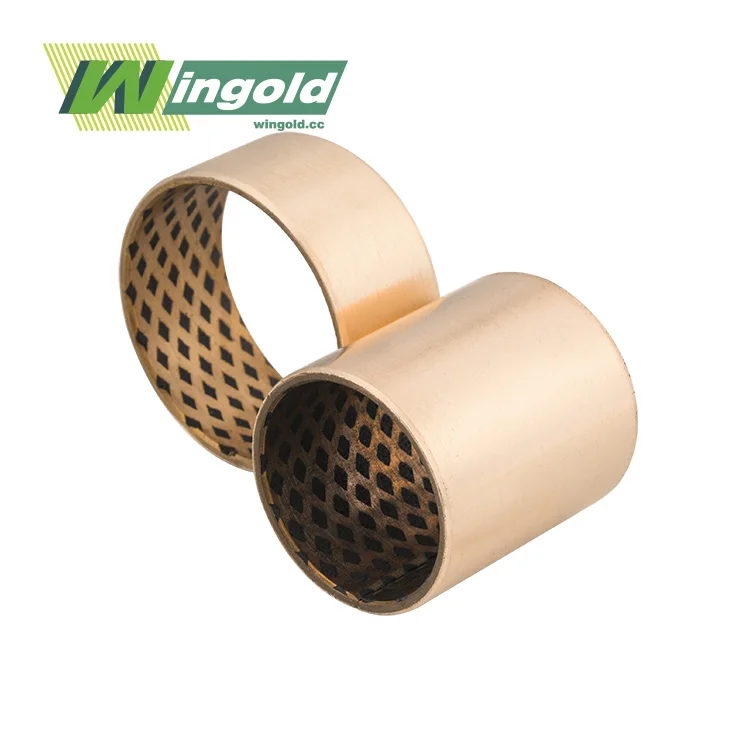

Many bronze alloys used in sleeve bushings possess inherent self-lubricating properties, a characteristic highly valued in automotive design. This self-lubrication is achieved through the presence of graphite or other solid lubricants within the bronze matrix. As the bushing operates, these lubricating particles are gradually released, creating a thin film on the bearing surface that reduces friction and wear.

The self-lubricating nature of bronze sleeve bushings offers several advantages in automotive applications. It reduces the need for frequent lubrication, simplifying maintenance procedures and reducing the risk of lubricant contamination. In hard-to-reach areas of a vehicle where regular lubrication is challenging, self-lubricating bronze bushings—and bronze self lubricating bearings that operate on the same solid-lubricant principle—provide a reliable, low-maintenance solution. This property also contributes to smoother operation and reduced noise levels in various automotive systems.

Critical Applications of Bronze Sleeve Bushings in Automotive Design

Engine and Powertrain Components

Bronze sleeve bushings play a vital role in engine and powertrain systems, where they are subjected to high loads, speeds, and temperatures. In these applications, the bushings' durability, wear resistance, and thermal properties are put to the test. Common uses include:

- Camshaft bearings: Bronze sleeve bushings support the camshaft, ensuring smooth rotation and precise valve timing.

- Connecting rod bushings: These bushings facilitate the pivoting motion between the connecting rod and piston pin, withstanding enormous forces during engine operation.

- Crankshaft thrust washers: Bronze bushings are used as thrust washers to control axial movement of the crankshaft.

- Transmission bushings: In both manual and automatic transmissions, bronze sleeve bushings support various shafts and gears, providing smooth operation and reducing wear.

Suspension and Steering Systems

The suspension and steering systems of a vehicle rely heavily on bronze sleeve bushings to provide smooth, controlled movement and absorb vibrations. Key applications include:

- Control arm bushings: These bushings allow for controlled movement of the suspension arms while dampening road vibrations.

- Kingpin bushings: In vehicles with kingpin steering systems, bronze bushings facilitate smooth steering action.

- Leaf spring bushings: Bronze sleeve bushings are used in leaf spring eyes to allow for flexing of the springs while minimizing wear.

- Sway bar bushings: These bushings permit the controlled movement of sway bars, enhancing vehicle stability during cornering.

Brake System Components

In brake systems, where reliability and consistent performance are critical, bronze sleeve bushings find several important applications:

- Brake caliper guide pins: Bronze bushings are used to support and guide caliper pins, ensuring smooth operation of floating calipers.

- Brake pedal bushings: These bushings provide a smooth pivot point for the brake pedal, enhancing pedal feel and durability.

- Parking brake mechanism: Various components of the parking brake system may utilize bronze bushings to ensure reliable operation.

Innovations in Bronze Sleeve Bushing Technology for Automotive Use

Advanced Alloy Formulations

The automotive industry's demand for higher performance and longevity has spurred innovations in bronze alloy formulations for sleeve bushings. Manufacturers like Wingold Bearing Co., Ltd. are developing specialized alloys that offer enhanced properties tailored to specific automotive applications. These advanced alloys may incorporate elements such as nickel, aluminum, or silicon to improve strength, wear resistance, and thermal stability.

One notable innovation is the development of high-density copper alloy strips used in products like the WGB-090 bronze bearings. These alloys offer increased load-bearing capacity and improved wear resistance compared to traditional bronze compositions. By applying these advanced alloys to bronze shoulder bushings, manufacturers can create components capable of handling higher axial and radial loads while maintaining precise alignment. The ability to fine-tune alloy compositions allows for the creation of bushings that can withstand the increasingly demanding conditions found in modern automotive designs, including higher operating temperatures and pressures.

Surface Engineering Techniques

Advancements in surface engineering have significantly enhanced the performance of bronze sleeve bushings in automotive applications. Techniques such as diamond rolling and the creation of specialized oil grooves and pockets have been developed to optimize the tribological properties of these components. For instance, the surface of WGB-090 bronze bearings can be rolled with diamond or hemispherical oil holes and oil grooves, tailored to specific user requirements.

These surface modifications serve multiple purposes:

- Improved lubrication retention and distribution

- Enhanced wear resistance

- Reduced friction coefficients

- Increased load-bearing capacity

Integration of Smart Technologies

As vehicles become increasingly sophisticated, there's a growing trend towards integrating smart technologies into various components, including bronze sleeve bushings. While still in early stages, research is being conducted on embedding sensors within or around bronze bushings to monitor key parameters such as temperature, wear, and load distribution in real-time.

This integration of smart technologies could revolutionize maintenance practices in the automotive industry by enabling predictive maintenance strategies. By continuously monitoring the condition of critical bushings, potential issues could be identified and addressed before they lead to component failure or vehicle downtime. This approach aligns with the broader trend towards connected and intelligent vehicle systems, promising to enhance reliability and reduce maintenance costs in future automotive designs.

Conclusion

Bronze sleeve bushings have proven to be indispensable components in modern automotive design, offering a unique combination of durability, performance, and cost-effectiveness. Their ability to withstand harsh operating conditions while providing smooth, low-friction operation makes them ideal for a wide range of automotive applications. As vehicle technology continues to evolve, the role of bronze sleeve bushings is likely to expand, driven by ongoing innovations in materials science and manufacturing techniques.

For automotive manufacturers seeking high-quality bronze sleeve bushings, partnering with a reputable supplier like Wingold Bearing Co., Ltd. can provide access to cutting-edge products and expertise. With our extensive experience in sliding bearing solutions and commitment to innovation, we offer customized bronze sleeve bushings that meet the exacting standards of the automotive industry. To learn more about our products and how they can enhance your automotive designs, please contact us at info@wingold.cc.

FAQs

What makes bronze sleeve bushings suitable for automotive applications?

Bronze sleeve bushings offer excellent durability, wear resistance, thermal conductivity, and self-lubricating properties, making them ideal for the demanding conditions in automotive systems.

Can bronze sleeve bushings reduce maintenance requirements in vehicles?

Yes, their self-lubricating properties and long service life can significantly reduce the need for frequent maintenance and replacements.

Are bronze sleeve bushings environmentally friendly?

Bronze is a recyclable material, and the longevity of bronze bushings contributes to reduced waste in the automotive industry.

How do bronze sleeve bushings compare to other bearing materials in automotive use?

Bronze bushings often outperform alternatives in terms of load capacity, wear resistance, and ability to operate in high-temperature environments.