Understanding the Mechanics of Oil Pump Bushings

Design and Construction

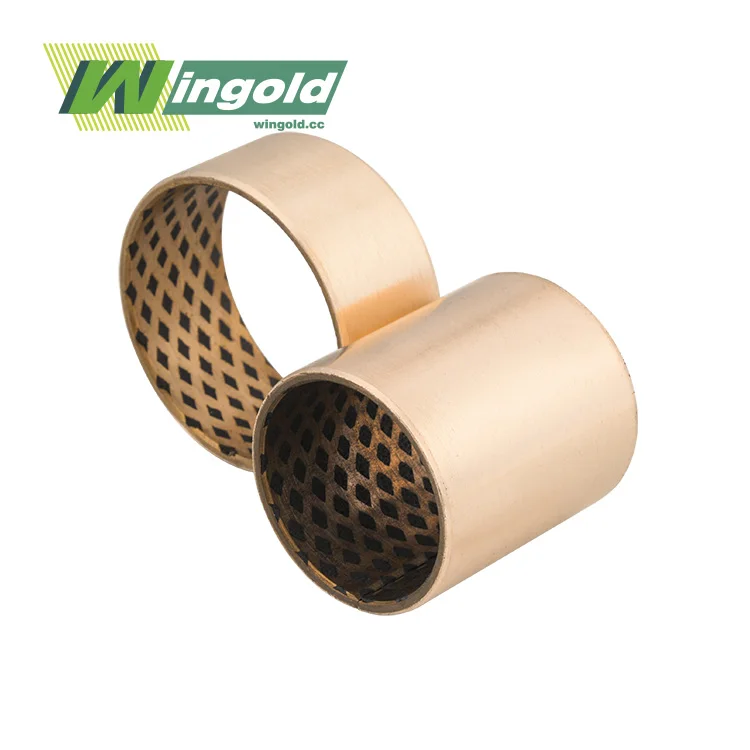

Oil pump bushings are meticulously crafted components designed to withstand the demanding conditions within oil pump systems. These cylindrical sleeves are typically manufactured using advanced metallurgy techniques, resulting in a product with exceptional wear resistance, low friction coefficients, and superior load-bearing capabilities. The design of oil pump bushings often incorporates features such as grooves or channels to facilitate proper oil distribution and maintain a consistent lubricating film.

Materials and Properties

The choice of materials for oil pump bushings is crucial to their performance. Common materials include bronze alloys, which offer excellent wear resistance and thermal conductivity, and babbitt metals, known for their low friction properties and ability to embed foreign particles. In addition, composite material bushings—featuring layered structures that combine strength, low friction, and enhanced chemical resistance—are increasingly used for applications requiring lightweight durability and reduced maintenance. Some manufacturers, like Wingold Bearing, also offer custom alloys tailored to specific application requirements. These materials are selected for their ability to withstand high temperatures, resist corrosion, and maintain dimensional stability under varying operating conditions.

Operational Principles

Oil pump bushings operate on the principle of hydrodynamic lubrication. As the pump shaft rotates within the bushing, it creates a thin film of oil between the two surfaces. This oil film acts as a cushion, reducing friction and wear while allowing for smooth rotation. The precise clearance between the bushing and the shaft is critical to maintaining this oil film and ensuring optimal pump performance. Advanced bushing designs, such as those based on the WGB-1P principle, incorporate features that enhance wear resistance and allow for operation even under conditions of limited lubrication.

Functions and Benefits of Oil Pump Bushings

Friction Reduction and Wear Minimization

One of the primary functions of oil pump bushings is to reduce friction between moving parts within the pump. By providing a smooth, low-friction surface, these bushings minimize wear on both the pump shaft and the bushing itself. This reduction in friction not only extends the lifespan of the pump components but also improves overall energy efficiency by reducing power consumption. Some advanced bushing designs, like those offered by Wingold Bearing, feature superior wear resistance performance even without oil lubrication, making them ideal for challenging operating conditions.

Alignment and Stability

Oil pump bushings play a crucial role in maintaining proper alignment of the pump shaft. By providing a stable, precision-engineered surface for the shaft to rotate within, bushings help prevent misalignment issues that could lead to increased wear, vibration, or premature failure. PTFE composite bushings are particularly advantageous in this role, as their low-friction, wear-resistant structure helps maintain smooth shaft rotation even under demanding conditions. This alignment function is especially important in high-speed or high-load applications, where even minor misalignments can have significant consequences.

Load Distribution and Support

Another key function of oil pump bushings is to distribute and support the loads placed on the pump shaft. The bushing's design and material properties allow it to effectively spread the load across its surface, reducing stress concentrations that could lead to premature wear or failure. This load-bearing capability is especially important in applications involving large lateral forces or frequent reciprocation, where the bushing must withstand significant stresses while maintaining its performance characteristics.

Applications and Industry Uses of Oil Pump Bushings

Automotive Industry

In the automotive sector, oil pump bushings are essential components in engine oil pumps, transmission pumps, and power steering systems. These bushings must withstand high temperatures, varying pressures, and constant operation while maintaining precise clearances. The performance of oil pump bushings directly impacts engine efficiency, fuel economy, and overall vehicle reliability. Advanced bushing designs, such as those with properties similar to DP4 material, offer exceptional durability and performance in automotive applications.

Oil and Gas Industry

The oil and gas industry relies heavily on oil pump bushings in various pumping applications, from extraction to refining processes. These bushings must operate in extremely demanding environments, often exposed to corrosive fluids, high pressures, and abrasive contaminants. Specialized oil pump bushings, designed for superior wear resistance and durability, are crucial for maintaining equipment reliability and minimizing downtime in this critical industry.

Industrial Machinery

Oil pump bushings find widespread use in industrial machinery across various sectors, including manufacturing, processing, and power generation. In these applications, bushings may be subjected to heavy loads, continuous operation, and exposure to diverse lubricants and chemicals. The versatility of oil pump bushings, combined with their ability to operate under challenging conditions, makes them indispensable components in hydraulic systems, compressors, and other industrial equipment.

Conclusion

Oil pump bushings are indispensable components that play a crucial role in ensuring the efficient and reliable operation of various pumping systems across multiple industries. Their ability to reduce friction, maintain alignment, and withstand challenging operating conditions makes them essential for optimizing performance and extending equipment lifespan. As technology continues to advance, innovations in bushing design and materials will further enhance their capabilities, meeting the ever-increasing demands of modern industrial applications.

For those seeking high-quality oil pump bushings, partnering with a reputable oil pump bushing supplier or manufacturer is crucial. Wingold Bearing, as a leading oil pump bushing manufacturer, offers a wide range of customized solutions designed to meet specific application requirements. With our expertise in advanced materials and precision engineering, we provide bushings that deliver superior performance, durability, and cost-effectiveness. To learn more about our oil pump bushing products or to discuss your specific needs, please contact us at info@wingold.cc.

Frequently Asked Questions

What are the typical dimensions of oil pump bushings?

Oil pump bushings can vary widely in size, with inner diameters ranging from 10mm to 500mm, outer diameters from 15mm to 600mm, and lengths from 10mm to 1000mm, depending on the specific application requirements.

What is the operating temperature range for oil pump bushings?

High-quality oil pump bushings, like those offered by Wingold Bearing, can typically operate in temperatures ranging from -40°C to 200°C, making them suitable for a wide variety of industrial applications.

How do oil pump bushings contribute to energy efficiency?

By reducing friction and ensuring proper alignment, oil pump bushings help minimize power consumption and improve overall system efficiency, leading to energy savings in various pumping applications.