The Innovative Structure of Bimetallic Self-Lubricating Bearings

Bimetallic self-lubricating bearings represent a pinnacle of bearing technology, combining the strengths of multiple materials to create a superior friction-reducing solution. At the core of these bearings lies a carefully engineered structure that maximizes performance and longevity.

Steel Backing: The Foundation of Strength

The backbone of a bimetallic self-lubricating bearing is its steel substrate. This layer provides the necessary structural integrity and load-bearing capacity essential for demanding applications. The steel backing is typically made from high-quality, low-carbon steel, chosen for its excellent mechanical properties and ability to withstand high stresses.

This robust foundation allows bimetallic self lubricating bearings to maintain their shape and function under extreme conditions, preventing deformation that could lead to increased friction or premature failure. The steel layer also acts as a heat sink, helping to dissipate thermal energy generated during operation, which further contributes to the bearing's ability to reduce friction and wear.

Self-Lubricating Layer: The Friction Fighter

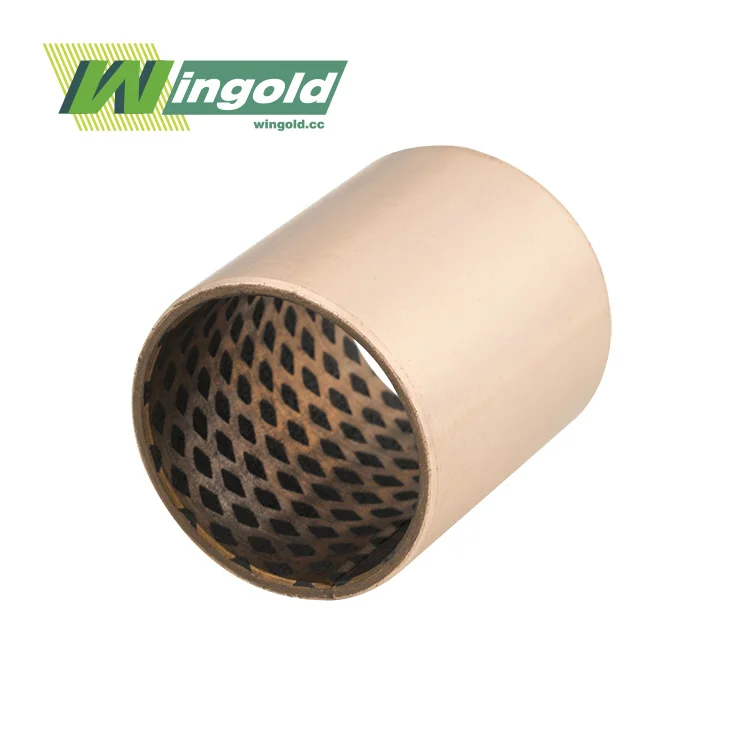

Bonded to the steel backing is a layer of self-lubricating material, often composed of bronze or aluminum alloys. This layer is the key to the bearing's friction-reducing prowess. Common alloys used in Wingold's bimetallic self-lubricating bearings include CuPb10Sn10, CuPb6Sn6Zn3, CuPb24Sn4, CuPb30, AlSn20Cu, and CuSn8Ni.

These alloys are carefully selected for their low friction characteristics and wear resistance. The surface of this layer is engineered with a network of microscopic pores, which are impregnated with lubricant during the manufacturing process. As the bearing operates, this lubricant is gradually released, creating a thin film between the moving surfaces that dramatically reduces friction.

Customized Surface Features

To further enhance the bearing's performance, the surface of the copper alloy layer can be customized with various features. These may include oil grooves, oil holes, and other patterns designed to optimize lubricant distribution and retention. Such features are particularly beneficial in applications where continuous external lubrication is impractical or impossible.

The ability to tailor these surface characteristics allows bimetallic self-lubricating bearings to be adapted for a wide range of operating conditions and environments, ensuring optimal friction reduction across diverse applications.

The Science Behind Friction Reduction in Bimetallic Bearings

The exceptional friction-reducing capabilities of bimetallic self-lubricating orientation are not just a result of their structure but are profoundly established in logical standards. Understanding these standards sheds light on why these heading are so viable at minimizing grinding in mechanical frameworks.

Tribological Considerations

Tribology, the science of interacting surfaces in relative motion, plays a crucial role in the design and function of bimetallic self-lubricating bearings. These bearings leverage several tribological concepts to achieve superior friction reduction:

- Boundary Lubrication: In the initial stages of operation or under high loads, the self-lubricating layer provides boundary lubrication. The lubricant trapped in the porous structure forms a thin film that prevents direct metal-to-metal contact, significantly reducing friction and wear.

- Hydrodynamic Lubrication: As the bearing reaches operating speed, the released lubricant can form a hydrodynamic film, further separating the surfaces and minimizing friction.

- Material Transfer: The softer alloy layer can transfer small amounts of material to the mating surface, creating a low-friction transfer film that enhances the overall tribological performance.

Thermal Management

Friction inevitably generates heat, which can lead to increased wear and decreased bearing performance. Bimetallic self-lubricating bearings address this issue through efficient thermal management:

- Heat Dissipation: The steel backing acts as an effective heat sink, conducting thermal energy away from the bearing surface.

- Temperature-Resistant Alloys: The self-lubricating layer is often composed of alloys that maintain their properties at elevated temperatures, ensuring consistent friction reduction even under thermally challenging conditions.

Load Distribution and Conformability

The composite nature of bimetallic self lubricating bearings allows for excellent load distribution and conformability:

- Micro-Conformability: The softer alloy layer can deform slightly to accommodate surface irregularities or misalignments, distributing the load more evenly and reducing localized high-pressure points that could increase friction.

- Macro-Stability: The steel backing maintains the overall bearing geometry, preventing excessive deformation that could lead to increased friction or bearing failure.

Applications and Performance Advantages of Bimetallic Self-Lubricating Bearings

The special properties of bimetallic self-lubricating heading make them perfect for a wide extend of applications over different businesses. Their capacity to diminish grinding viably deciphers into various execution preferences that advantage both producers and end-users.

Diverse Industrial Applications

Bimetallic self-lubricating bearings find use in numerous sectors, including:

- Automotive: Used in suspension systems, steering mechanisms, and transmission assemblies, these bearings help improve vehicle performance and fuel efficiency by reducing friction-related energy losses.

- Aerospace: In aircraft landing gear and flap track mechanisms, bimetallic self-lubricating bearings provide reliable operation under extreme conditions with minimal maintenance requirements.

- Industrial Machinery: Printing presses, textile manufacturing equipment, and packaging machinery benefit from the long service life and reduced downtime offered by these bearings.

- Construction Equipment: Excavators, bulldozers, and cranes utilize bimetallic self-lubricating bearings in high-stress pivot points to ensure smooth operation and extended equipment life.

- Marine Applications: Ship rudder systems and propeller shaft bearings rely on the corrosion resistance and low-friction properties of these bearings to maintain optimal performance in harsh marine environments.

Performance Advantages

The implementation of bimetallic self lubricating bearings offers several key performance advantages:

- Extended Service Life: By significantly reducing friction and wear, these bearings can operate for extended periods without replacement, reducing maintenance costs and downtime.

- Improved Energy Efficiency: Lower friction translates to reduced energy consumption in mechanical systems, contributing to overall efficiency improvements and potential energy savings.

- Enhanced Load Capacity: The combination of a strong steel backing and a conformable alloy layer allows these bearings to handle higher loads compared to traditional bearing solutions.

- Operational in Extreme Conditions: Bimetallic self-lubricating bearings can function effectively in a wide range of temperatures (-40°C to 280°C) and harsh environments where traditional lubrication methods may fail.

- Maintenance Reduction: The self-lubricating nature of these bearings eliminates or greatly reduces the need for regular lubrication, simplifying maintenance procedures and reducing associated costs.

Cost-Effectiveness and ROI

While the initial cost of bimetallic self-lubricating bearings may be higher than some traditional alternatives, their long-term benefits often result in a superior return on investment:

- Reduced Downtime: Longer service intervals and reduced maintenance needs translate to less production downtime, increasing overall equipment effectiveness.

- Lower Total Cost of Ownership: The combination of extended service life, reduced maintenance requirements, and improved energy efficiency often results in a lower total cost of ownership over the life of the equipment.

- Improved Product Quality: In manufacturing applications, the consistent, low-friction performance of these bearings can contribute to improved product quality and reduced scrap rates.

Conclusion

Bimetallic self lubricating bearings represent a significant advancement in bearing technology, offering unparalleled friction reduction and performance benefits across a wide range of applications. By combining the strength of a steel backing with the low-friction properties of carefully selected alloys, these bearings provide a robust, long-lasting solution to the age-old problem of friction in mechanical systems.

As industries continue to demand higher efficiency, longer service life, and reduced maintenance in their equipment, bimetallic self-lubricating bearings are poised to play an increasingly important role. Their ability to operate in extreme conditions, coupled with their self-lubricating properties, makes them an ideal choice for applications where traditional bearings fall short.

For those seeking to optimize their mechanical systems and reduce friction-related losses, bimetallic self-lubricating bearings offer a compelling solution. To learn more about how these innovative bearings can benefit your specific application, or to explore the range of bimetallic self-lubricating bearing options available, please contact Wingold Bearing at info@wingold.cc. Our team of experts is ready to help you find the perfect bearing solution to meet your needs and enhance your equipment's performance.