The Unparalleled Advantages of Bronze Bearings in Industrial Settings

When it comes to selecting materials for heading in mechanical applications, bronze stands out as a prevalent choice. The best bronze for bearing offers a huge number of preferences that make it vital in different divisions. Let's dive into the key benefits that make bronze heading a vital component in mechanical apparatus.

Exceptional Wear Resistance and Longevity

One of the primary reasons for choosing bronze bearings is their remarkable wear resistance, which ensures long-lasting performance in demanding environments. High-quality bronze alloys, such as those produced by Jiashan Wingold Bearing Co., Ltd., demonstrate exceptional durability even under extreme conditions like high pressure and temperature. This outstanding wear resistance translates into an extended lifespan for machinery components and reduces the frequency of bearing replacements, ultimately leading to significant cost savings and less downtime for industrial operations.

Low Friction and Smooth Operation

The best bronze for bearing is known for their impressively low friction coefficient, typically ranging from 0.08 to 0.12, which enables smooth and efficient machinery operation. This low friction reduces energy consumption and minimizes heat generation during use, helping to protect other machine components from premature wear. The resulting improvement in operational efficiency not only enhances system performance but also contributes to longer service life and decreased maintenance requirements in various industrial applications.

High Load-Bearing Capacity

Industrial machinery often requires bearings capable of handling substantial loads without deformation or failure. Bronze bearings meet this demand effectively, with some variants designed to withstand loads up to 140 MPa. Their high load-bearing capacity makes them suitable for use in heavy-duty equipment found in industries such as construction, mining, and manufacturing. This robust performance under heavy stress ensures reliability and longevity, even in the most challenging industrial environments.

Innovative Features of Modern Bronze Bearings

The best bronze for bearing solutions incorporates cutting-edge features that enhance their performance and extend their utility across diverse industrial applications. These innovations have revolutionized the capabilities of bronze bearings, making them more versatile and efficient than ever before.

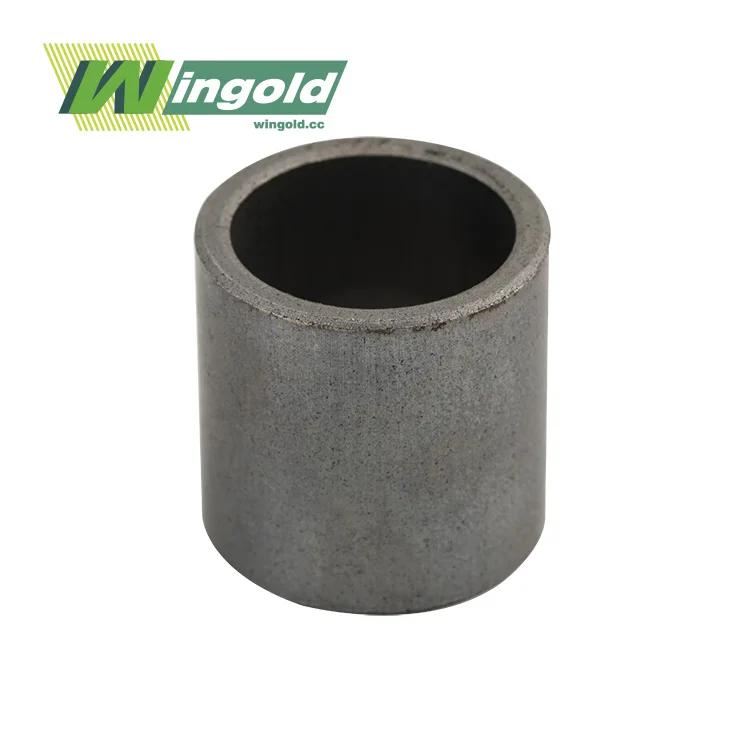

Self-Lubricating Properties

Advanced bronze alloys used in modern bearings often possess self-lubricating properties. This characteristic significantly reduces the need for frequent lubrication, leading to lower maintenance requirements and improved reliability. The self-lubricating nature of these bearings is particularly beneficial in applications where regular maintenance access is challenging or costly.

Corrosion Resistance

Bronze bearings exhibit excellent corrosion resistance, making them suitable for use in harsh environments. This property is especially valuable in marine applications, chemical processing plants, and other settings where exposure to corrosive elements is common. The corrosion resistance of bronze bearings ensures their longevity and reliability even under challenging conditions.

Thermal Conductivity

Another advantage of bronze bearings is their excellent thermal conductivity. This property allows for efficient heat dissipation, helping to maintain optimal operating temperatures in machinery. Effective heat management is crucial for preserving the integrity of both the bearing and the surrounding components, contributing to overall system reliability.

Tailored Solutions: Customizing Bronze Bearings for Specific Industrial Needs

The versatility of bronze as a bearing material allows for customization to meet specific industrial requirements. Manufacturers like Jiashan Wingold Bearing Co., Ltd. offer a range of bronze alloys and bearing designs to address the unique challenges faced by different industries.

Alloy Selection for Optimal Performance

Different bronze alloys offer varying properties suited to specific applications. For instance, aluminum bronze may be preferred for its strength and corrosion resistance in marine environments, while phosphor bronze might be chosen for its excellent wear resistance in high-speed applications. The selection of the best bronze for bearing in a particular scenario depends on factors such as load requirements, operating speeds, and environmental conditions.

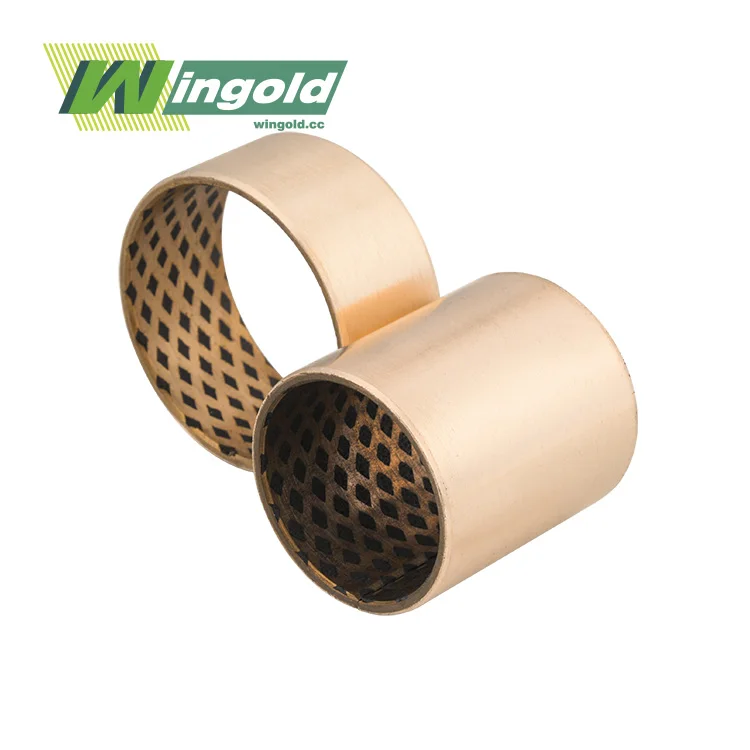

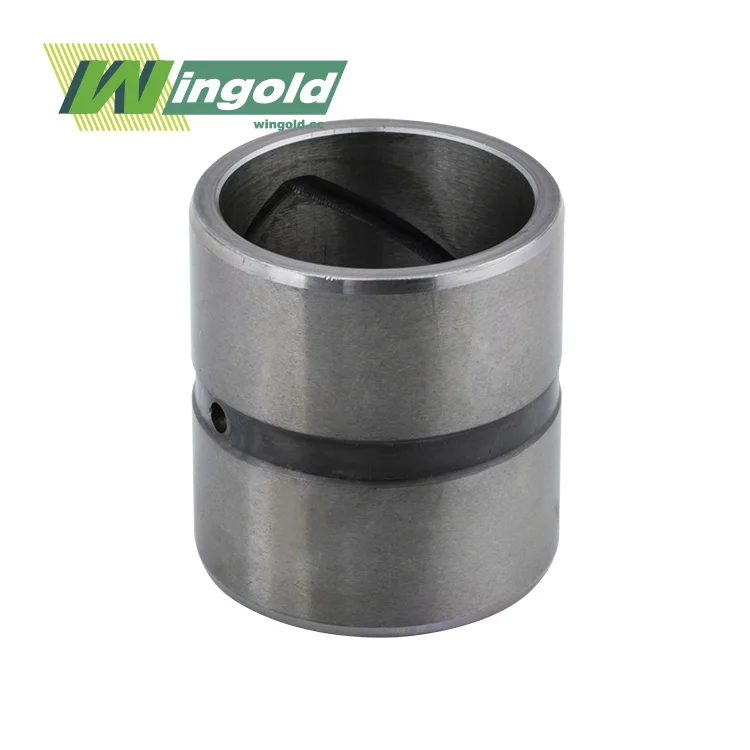

Innovative Design Features

Modern bronze bearings often incorporate innovative design features to enhance their performance. These may include specially synthesized internal surfaces using high-density bronze roll forming techniques or the integration of spherical oil bags and oil holes. Such features can significantly reduce wear, extend service life, and improve anti-corrosion properties.

Size and Configuration Options

Bronze bearings are available in a wide range of sizes and configurations to suit various industrial needs. From small bearings with inner diameters of 10mm to large ones up to 500mm, manufacturers offer solutions for machinery of all scales. Additionally, different configurations such as straight sleeves, thrust washers, flanged bushings, and slide plates provide options for diverse application requirements.

Conclusion

The best bronze for bearing solutions plays a crucial role in ensuring the efficiency, reliability, and longevity of industrial machinery across numerous sectors. Their unique combination of properties, including exceptional wear resistance, low friction, high load-bearing capacity, and corrosion resistance, makes them indispensable in modern industrial applications. As technology continues to advance, we can expect further innovations in bronze bearing design and materials, leading to even more efficient and durable solutions for industrial challenges.

For more information about high-quality bronze bearing solutions tailored to your specific industrial needs, please contact Jiashan Wingold Bearing Co., Ltd. at info@wingold.cc. Our team of experts is ready to assist you in finding the perfect bearing solution for your application.