The Exceptional Properties of Bronze Bearings in High-Temperature Applications

When it comes to selecting the best bronze for bearing in high-heat environments, understanding the material's unique properties is essential. Bronze alloys, particularly those engineered for extreme conditions, offer a combination of characteristics that make them ideal for reducing maintenance in hot operational settings.

Thermal Conductivity and Heat Dissipation

One of the most critical focal points of bronze orientation is their predominant warm conductivity. This property permits the bearing to effectively exchange warm absent from the contact surfaces, avoiding localized hot spots and decreasing the chance of warm harm. The capacity to scatter warm rapidly makes a difference keep up reliable working temperatures, which is pivotal for protecting the bearing's auxiliary astuteness and execution over time.

High-Temperature Strength and Stability

The best bronze for bearing applications in high-heat environments maintains its strength and dimensional stability even at elevated temperatures. This thermal resilience ensures that the bearing continues to function effectively without deforming or losing its critical tolerances. The stability of bronze bearings at high temperatures contributes significantly to their longevity and reduced maintenance requirements.

Wear Resistance in Hot Conditions

Bronze amalgams designed for bearing applications show remarkable wear resistance, indeed when subjected to tall temperatures. This toughness is somewhat due to the arrangement of a defensive oxide layer on the surface of the bronze, which acts as a boundary against encourage wear and erosion. The combination of wear resistance and warm soundness implies that bronze orientation can work for amplified periods in hot situations without requiring visit substitutions or alterations.

Self-Lubricating Properties and Their Impact on Maintenance Reduction

The self-lubricating nature of bronze bearings is a key factor in their ability to reduce maintenance requirements, especially in high-heat applications where traditional lubricants may break down or evaporate quickly.

Microscopic Oil Retention

Bronze bearings, particularly those made from the best bronze for bearing applications and featuring engineered porosity, can retain microscopic amounts of oil within their structure. This characteristic allows the bearing to maintain a thin film of lubricant even under extreme conditions. By continuously supplying lubricant where it's most needed, these porous bearings help reduce friction and wear without requiring constant relubrication, making them highly effective for demanding industrial applications with limited maintenance access.

Formation of Graphite Films

In high-temperature environments, certain bronze alloys can form a thin layer of graphite on their surface. This graphite film acts as a solid lubricant, further reducing friction and wear even when liquid lubricants have been depleted or rendered ineffective due to extreme heat. This self-lubricating behavior ensures continued performance and protects critical components, especially in harsh applications subject to intense thermal stress and fluctuating temperaturest.

Extended Lubrication Intervals

The combination of oil retention and solid lubricant formation significantly extends the intervals between lubrication cycles. This extension not only reduces maintenance frequency but also minimizes the risk of unexpected equipment downtime and the associated costs of regular servicing. As a result, operators benefit from improved system reliability, increased productivity, and overall lower total cost of ownership, making bronze bearings an efficient choice for various demanding industrial environments.

Design Innovations for Enhanced Performance in High-Heat Environments

Manufacturers of high-quality bronze bearings have developed innovative design features to further enhance their performance and reduce maintenance requirements in high-temperature applications.

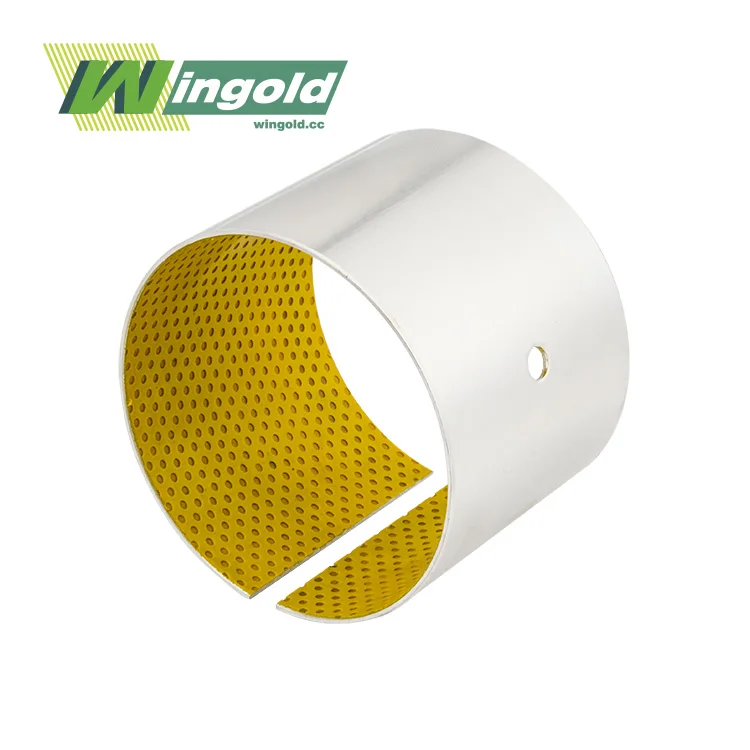

Engineered Surface Textures

Advanced manufacturing techniques allow for the creation of micro-textured surfaces on best bronze for bearing. These engineered textures can significantly improve oil retention by trapping lubricant within microscopic grooves, enhance heat dissipation by increasing surface area, and promote the formation of stable hydrodynamic lubricating films. Together, these benefits contribute to smoother operation, reduced friction, and lower maintenance needs across a range of demanding industrial applications.

Customized Alloy Compositions

By tailoring the composition of bronze alloys, manufacturers can optimize bearings for specific high-heat applications. For instance, adding elements like nickel or aluminum not only improves the alloy's strength but also enhances resistance to corrosion and thermal fatigue at elevated temperatures. This customization helps extend the bearing's service life, reduce downtime, and lower overall maintenance requirements in challenging operating environments.

Integrated Cooling Channels

Some advanced bronze bearings incorporate internal cooling channels or external fins to enhance heat dissipation during operation. These design features effectively lower the bearing's operating temperature by directing heat away from critical surfaces. Maintaining cooler conditions helps preserve lubricant properties, reduce thermal expansion, and minimize component wear, which together contribute to extended service intervals and reduced need for frequent maintenance interventions.

Conclusion

The best bronze for bearing applications in high-heat environments offers a compelling solution for reducing maintenance requirements. Through a combination of excellent thermal properties, wear resistance, and self-lubricating characteristics, bronze bearings provide extended service life and improved reliability in challenging thermal conditions. As industries continue to push the boundaries of operational temperatures, the role of high-quality bronze bearings in minimizing maintenance and maximizing equipment efficiency becomes increasingly critical.

For more information on how our premium bronze bearings can help reduce maintenance in your high-heat applications, please contact us at info@wingold.cc. Our team of experts is ready to assist you in finding the optimal bearing solution for your specific needs.