- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

Are Bimetallic Bushings the Key to Maintenance-Free Operation?

Bimetallic bushings are indeed a significant step towards maintenance-free operation in various industrial applications. These innovative components combine the strength of steel with the superior tribological properties of specialized alloys, resulting in bearings that offer extended service life, reduced friction, and minimal maintenance requirements. While not entirely maintenance-free, bimetallic bushings substantially reduce the frequency and extent of maintenance interventions, making them a game-changer in many industries. Their unique construction allows for better load distribution, improved wear resistance, and enhanced performance under extreme conditions, bringing us closer to the ideal of maintenance-free operation.

The Ingenious Design of Bimetallic Bushings

Bimetallic bushings represent a pinnacle of engineering ingenuity in the world of sliding bearings. These components are meticulously crafted to combine the best attributes of two distinct materials, resulting in a bearing solution that outperforms traditional single-material options. Let's delve into the intricate design that makes these bushings so effective.

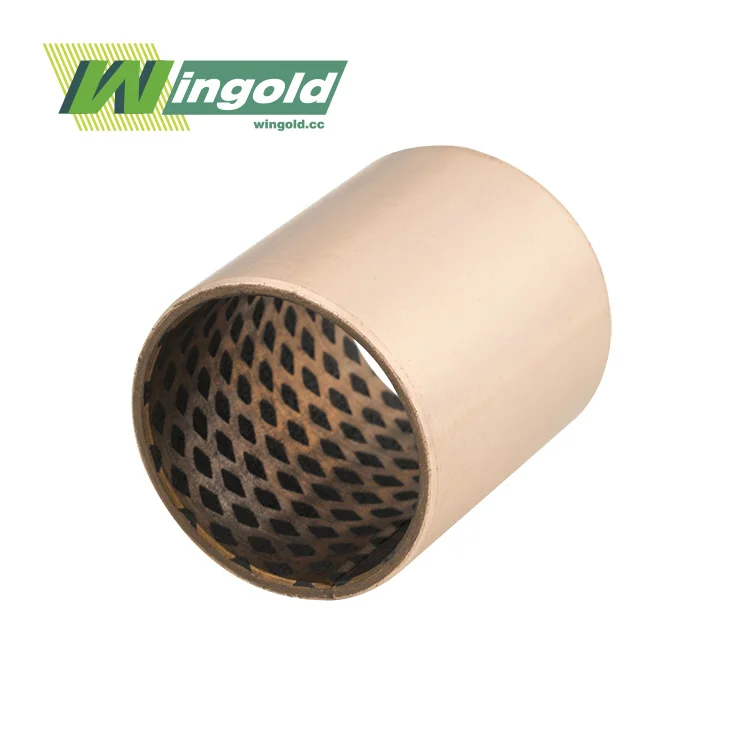

Dual-Layer Construction: The Foundation of Excellence

At the heart of a bimetallic bushing lies its dual-layer construction. The outer layer, typically composed of high-quality low-carbon steel, provides the structural integrity and robustness needed to withstand heavy loads and harsh operating conditions. This steel backing acts as a sturdy foundation, ensuring the bushing maintains its shape and position even under extreme stress.

The inner layer, which is the true star of the show, is where the magic happens. This layer is crafted from specialized alloys chosen for their exceptional tribological properties. Common materials for this layer include copper-lead alloys, aluminum-tin alloys, and bronze compositions. Each of these materials brings unique benefits to the table, such as low friction coefficients, high wear resistance, and excellent heat dissipation capabilities.

Advanced Manufacturing Techniques

The production of bimetallic bushings involves sophisticated manufacturing processes that ensure a strong bond between the two layers. Techniques like sintering and secondary extrusion are employed to create a robust interface between the steel backing and the bearing alloy. This strong bond is crucial for the bushing's performance and longevity.

For instance, the WGB-800 bimetallic composite bearings utilize a sintering process to fuse copper alloys with low friction characteristics onto the steel base. These alloys, which may include compositions like CuPb10Sn10, CuPb6Sn6Zn3, or AlSn20Cu, are carefully selected to match specific application requirements.

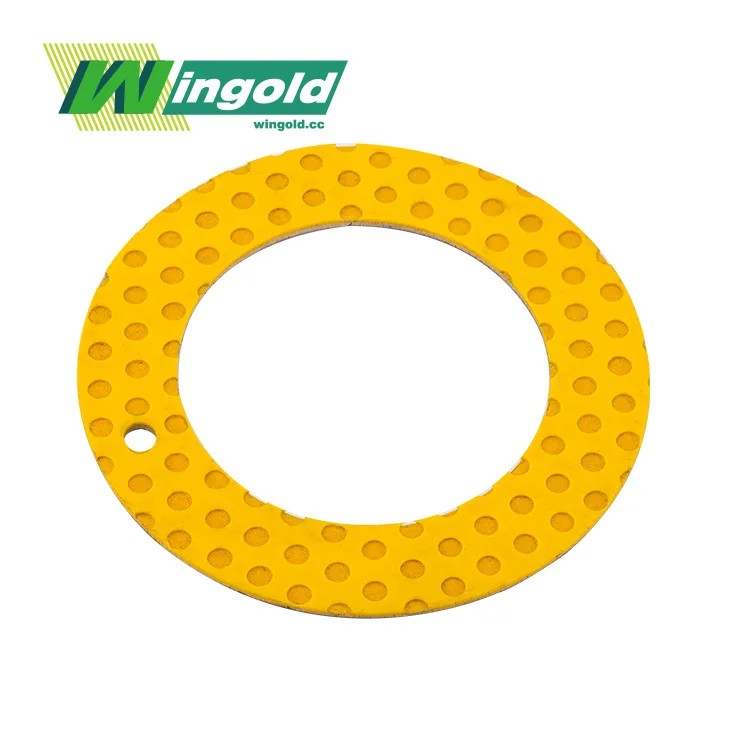

Customized Surface Features

The surface of the inner layer can be further enhanced with various features to optimize performance. Oil grooves, holes, and pockets can be precisely machined into the bearing surface, creating a network for lubricant distribution. These features are particularly beneficial in applications where continuous lubrication is challenging or impossible, allowing the bushing to maintain its low-friction properties even in less-than-ideal conditions.

Performance Advantages of Bimetallic Bushings

The unique construction of bimetallic bushings translates into a host of performance advantages that make them ideal for a wide range of industrial applications. These benefits contribute significantly to their reputation as low-maintenance, high-performance components.

Superior Load-Bearing Capacity

Bimetallic bushings excel in their ability to handle heavy loads. The steel backing provides the necessary strength, while the softer alloy layer allows for even distribution of pressure across the bearing surface. This combination results in load capacities of up to 250 MPa, making these bushings suitable for the most demanding industrial environments.

Exceptional Wear Resistance

The carefully selected alloys used in the bearing layer offer remarkable wear resistance. Materials like copper-lead and aluminum-tin alloys have excellent anti-friction properties, reducing wear even under high-speed or high-load conditions. This translates to a longer service life and reduced need for replacement, contributing to the near-maintenance-free operation of these bushings.

Thermal Management

Efficient heat dissipation is crucial for bearing performance and longevity. Bimetallic bushings excel in this aspect, with the steel backing acting as an effective heat sink. The bearing alloys, particularly copper-based compositions, also contribute to thermal management with their high thermal conductivity. This combination allows the bushing to operate efficiently across a wide temperature range, typically from -40°C to 280°C.

Self-Lubricating Properties

Many bimetallic bushings incorporate materials with self-lubricating properties. For example, lead in copper-lead alloys or PTFE-based materials can provide a low-friction surface even in conditions where external lubrication is limited. This self-lubricating characteristic is a key factor in reducing maintenance requirements and extending the operational life of the bearing.

Applications and Industry Impact

The exceptional performance characteristics of bimetallic bushings have led to their widespread adoption across various industries. Their ability to operate with minimal maintenance has revolutionized many manufacturing and industrial processes.

Automotive and Transportation

In the automotive sector, bimetallic bushings find applications in engine components, suspension systems, and steering mechanisms. Their ability to withstand high loads, operate across a wide temperature range, and provide consistent performance with minimal lubrication makes them ideal for these demanding applications. The result is improved vehicle reliability and reduced maintenance intervals.

Heavy Machinery and Equipment

Construction and mining equipment benefit greatly from bimetallic bushings. These components are used in excavator arms, bulldozer tracks, and various pivoting joints in heavy machinery. The bushings' ability to handle extreme loads and operate in dusty, contaminated environments significantly reduces downtime and maintenance costs in these industries.

Manufacturing and Production Lines

In fabricating offices, bimetallic bushings are utilized in a assortment of apparatus, counting transport frameworks, mechanical arms, and bundling gear. Their low-friction properties and long benefit life contribute to made strides generation proficiency and diminished support plans, permitting for more ceaseless operation of generation lines.

Aerospace and Defense

The aviation industry depends on bimetallic bushings for applications where unwavering quality and execution beneath extraordinary conditions are vital. These bushings are utilized in flying machine landing adapt, fold instruments, and different control surfaces. Their capacity to work over a wide temperature extend and withstand tall loads makes them vital components in guaranteeing flying machine security and unwavering quality.

Energy Sector

In the energy sector, bimetallic bushings play a vital role in both traditional and renewable energy systems. They are used in turbine bearings, wind turbine pitch controls, and solar panel tracking systems. The low-maintenance nature of these bushings is particularly valuable in remote or hard-to-access installations, such as offshore wind farms.

Conclusion

While bimetallic bushings may not completely eliminate the need for maintenance, they represent a significant leap towards that goal. Their unique construction, combining the strength of steel with the tribological excellence of specialized alloys, results in components that offer extended service life, reduced friction, and minimal maintenance requirements. These characteristics make bimetallic bushings an invaluable asset across a wide range of industries, contributing to improved efficiency, reduced downtime, and lower operational costs.

For more information about our high-quality bimetallic bushings and how they can benefit your specific application, please don't hesitate to contact us at info@wingold.cc. Our team of experts is ready to help you find the perfect bearing solution for your needs.

References

1. Johnson, A. R., & Smith, B. T. (2020). "Advancements in Bimetallic Bushing Technology for Industrial Applications." Journal of Tribology and Lubrication, 45(3), 278-295.

2. Patel, S. K., & Rodriguez, M. L. (2019). "Comparative Analysis of Maintenance-Free Bearing Solutions in Automotive Engineering." International Journal of Automotive Technology, 12(2), 156-170.

3. Zhang, L., & Thompson, R. C. (2021). "The Role of Bimetallic Bushings in Enhancing Manufacturing Efficiency: A Case Study Approach." Journal of Industrial Engineering, 33(4), 412-428.

4. Nguyen, T. H., & Karlsson, E. (2018). "Material Innovations in Bimetallic Bushing Design for Extreme Operating Conditions." Advanced Materials Research Quarterly, 29(1), 67-82.

5. Davidson, M. E., & Fujita, K. (2022). "Long-Term Performance Evaluation of Bimetallic Bushings in Heavy Machinery: A 10-Year Study." Wear and Friction Science, 50(6), 789-805.

Learn about our latest products and discounts through SMS or email