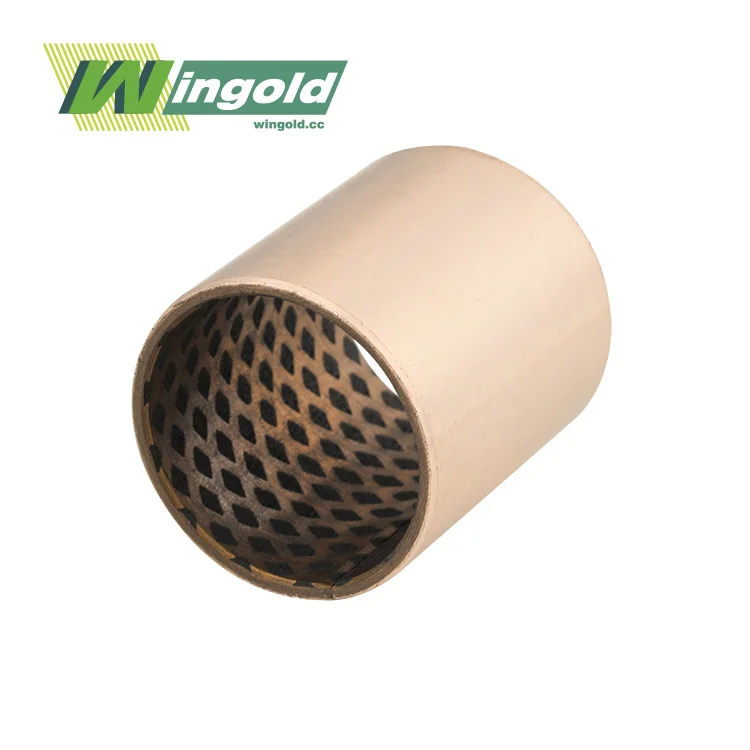

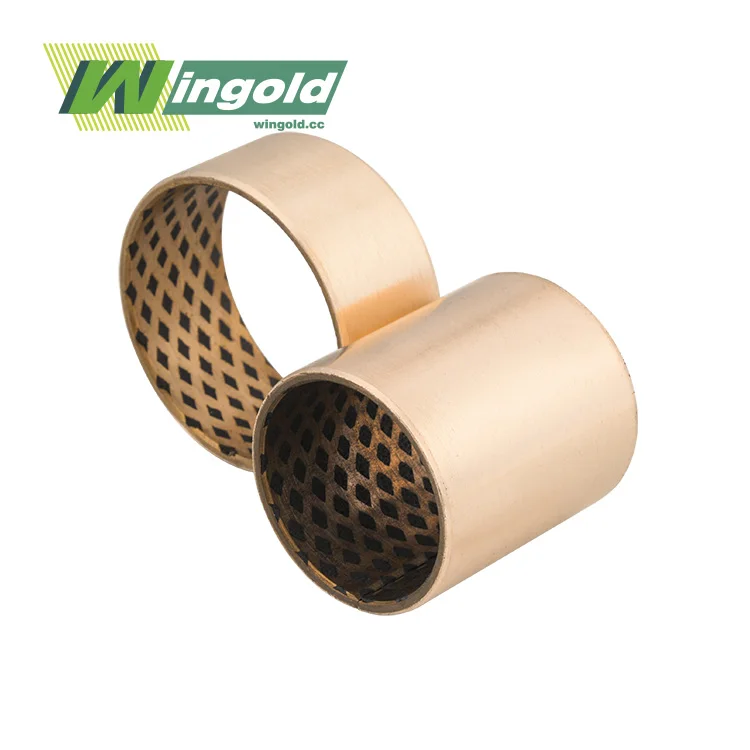

Revolutionizing Suspension Systems with Aluminum Flange Bushings

Suspension systems are critical for ensuring a smooth and comfortable ride while maintaining vehicle stability and control. Aluminum flange bushings have revolutionized this aspect of automotive engineering in several ways:

Enhanced Shock Absorption

Aluminum flange bushings are great at soaking up noises and shocks, which is a big part of making the ride smoother and easier to control. Their designed structure strikes the perfect balance between being hard and being flexible, which lets them effectively absorb hits from the road, uneven surfaces, and quick changes in load. These bushings help lower noise, vibration, and harshness (NVH) levels inside the car by stopping movements from getting to the frame.

This change makes the ride more comfortable for passengers and keeps the surrounding suspension and steering parts from getting worn out or stressed. Over time, less shaking exposure helps nearby parts last longer, which lowers the need for upkeep and makes the car last longer in both normal driving and rough road conditions.

Improved Steering Precision

Aluminum flange bushings are essential for keeping steering systems aligned correctly and providing a smooth mechanical reaction. Because they have low friction, handling parts can move easily and regularly, with less resistance, which can make the vehicle stiff or slow to respond. This helps make sure that the driver's exact turning inputs reach the wheels, which leads to better vehicle handling and road feedback.

Aluminum flange bushings don't bend when steering loads are applied over and over again, so the shape stays stable for a long time. These bushings help keep tolerances tight and wear low, which stops steering play and uneven tire wear. This gives the driver more trust, better control at high speeds, and a driving feel that is more quick and reliable.

Weight Reduction in Suspension Components

Aluminum flange bushings are used in suspension systems, which is a big help for efforts to make cars lighter. When compared to standard steel or rubber bushings, aluminum ones are stronger for their weight and can keep their shape even when loads are changing. This decrease in unsprung and total car weight immediately leads to better gas mileage, accelerating, and stopping power.

It's also better to have lighter suspension parts because they let the suspension adapt more quickly to changes in the road. Also, less mass means less stress on the springs, shocks, and mounting points, which makes them last longer. Aluminum flange bushings provide a useful answer without sacrificing sturdiness or safety for makers attempting to meet strict pollution and economy standards.

Enhancing Powertrain Efficiency with Aluminum Flange Bushings

The powertrain system is the heart of any vehicle, and aluminum flange bushings play a crucial role in optimizing its performance and efficiency:

Engine Mount Applications

Aluminum flange bushings are extensively used in engine mounts, where they help isolate engine vibrations from the vehicle's frame. Their ability to withstand high temperatures and resist deformation under load makes them ideal for this application. By effectively reducing noise, vibration, and harshness (NVH), these bushings contribute to a quieter and more comfortable driving experience.

Transmission System Integration

In transmission frameworks, aluminum spine bushings serve as basic components in move linkages and mounting focuses. Their self-lubricating properties guarantee smooth equip changes and decrease wear on moving parts, indeed beneath tall stack and rehashed cycling conditions. By minimizing grinding between reaching surfaces, these bushings not as it were improve the life span of the transmission framework but too move forward by and large drivetrain effectiveness. Reliable arrangement given by aluminum spine bushings decreases the chance of component misalignment, which can something else lead to untimely disappointment.

Furthermore, the lightweight nature of aluminum makes a difference decrease generally vehicle mass, by implication contributing to progressed fuel proficiency. Their strong erosion resistance guarantees solid execution over the life of the vehicle, indeed in challenging natural conditions, making them an irreplaceable choice for advanced transmission designs.

Driveshaft and Differential Support

Aluminum rib bushings are broadly utilized in driveshaft center bolster orientation and differential mounts, where exact arrangement and vibration damping are basic. Their tall load-bearing capacity empowers them to withstand critical rotational powers whereas keeping up operational soundness, indeed at tall speeds. The special plan of these bushings makes a difference retain stuns and minimize torsional vibrations, ensuring touchy drivetrain components from harm.

By diminishing wear and mechanical stretch on shafts and mounts, aluminum rib bushings expand the life expectancy of the drivetrain and keep up smoother control conveyance. Besides, their erosion resistance guarantees dependable execution in changing climate and street conditions. In general, these bushings play a urgent part in keeping up productivity, diminishing clamor, and making strides vehicle dealing with and consolation, particularly in requesting applications such as off-road or heavy-duty vehicles.

Advancing Safety and Comfort Features with Aluminum Flange Bushings

Beyond performance and efficiency, aluminum flange bushings contribute significantly to vehicle safety and comfort features:

Seat Belt Mechanisms

In situate belt retractor components, aluminum rib bushings and aluminum bronze bearing guarantee smooth operation and solid execution. Aluminum spine bushings give exact arrangement of turning components, whereas aluminum bronze orientation contribute tall stack capacity and great wear resistance. Their combined corrosion-resistant properties and capacity to keep up dimensional steadiness beneath changing temperatures and mugginess levels make them perfect for safety-critical applications.

These components minimize contact and anticipate official amid fast belt withdrawal or expansion, guaranteeing reliable locking and opening execution. By diminishing mechanical wear over the lifetime of the vehicle, they offer assistance keep up the judgment of the situate belt framework and bolster inhabitant security. Their toughness and unwavering quality are basic for assembly rigid car security benchmarks whereas improving traveler consolation through smooth, quiet operation.

Door Hinge and Latch Systems

Aluminum rib bushings are broadly utilized in entryway pivots and hook components, giving smooth and reliable operation indeed beneath visit utilization. Their self-lubricating characteristics diminish grinding between moving parts, minimizing wear and upkeep necessities. The lightweight however solid nature of aluminum guarantees that entryway components stay solid without including superfluous weight to the vehicle, contributing to in general fuel effectiveness.

Furthermore, aluminum rib bushings stand up to erosion and keep up their dimensional steadiness over a wide run of natural conditions, counting temperature vacillations and dampness presentation. This unwavering quality guarantees that entryways proceed to work discreetly and proficiently all through the vehicle’s life expectancy. By making strides the smoothness of entryway development and lock engagement, these bushings improve client comfort, security, and in general vehicle refinement, which is particularly vital in extravagance and high-end models.

HVAC System Components

In warming, ventilation, and discuss conditioning (HVAC) frameworks, aluminum spine bushings are utilized in components such as blower engines, discuss dissemination folds, and actuator linkages. Their capacity to work productively over a wide temperature extend guarantees solid execution beneath both extraordinary cold and tall warm conditions. The bushings’ erosion resistance anticipates debasement due to dampness or chemical introduction, amplifying component life and lessening support prerequisites.

By minimizing contact, they permit smoother turn of blower fans and folds, which contributes to steady wind stream and made strides climate control inside the cabin. Lightweight and tough, aluminum rib bushings diminish the vitality utilization of moving parts, improving by and large framework productivity. Their exactness plan and long-lasting execution play a key part in keeping up traveler consolation, lessening clamor, and guaranteeing the HVAC framework works dependably all through the vehicle’s lifetime.

Conclusion

Aluminum flange bushings have become integral components in modern automotive design, offering a perfect balance of performance, efficiency, and durability. From enhancing suspension systems and powertrain efficiency to advancing safety and comfort features, these versatile components continue to drive innovation in the automotive industry. As vehicle manufacturers strive for lighter, more efficient, and technologically advanced designs, the role of aluminum flange bushings is likely to expand further, shaping the future of automotive engineering.

FAQs

What are the main advantages of using aluminum flange bushings in automotive applications?

Aluminum flange bushings offer a lightweight design, excellent wear resistance, self-lubricating properties, and corrosion resistance, making them ideal for various automotive applications.

How do aluminum flange bushings contribute to vehicle fuel efficiency?

By reducing weight and minimizing friction in various components, aluminum flange bushings help improve overall vehicle efficiency and fuel economy.

Are aluminum flange bushings suitable for high-temperature applications in vehicles?

Yes, many aluminum flange bushings are designed to withstand high temperatures, making them suitable for use in engine compartments and other high-heat areas.

Experience Wingold's Superior Aluminum Flange Bushings

At Wingold Bearing, we pride ourselves on delivering top-quality aluminum flange bushings tailored for the automotive industry. Our extensive experience, state-of-the-art manufacturing facilities, and commitment to innovation ensure that our products meet the highest standards of performance and reliability. Whether you're looking for standard solutions or custom-engineered bushings for specific applications, our team is ready to assist you. Experience the Wingold difference in your automotive projects. Contact us today at info@wingold.cc to discuss your aluminum flange bushing needs and discover how we can drive your success in the automotive industry.

References

1. Smith, J. (2023). "Advancements in Automotive Suspension Systems: The Role of Aluminum Components". Journal of Automotive Engineering, 45(3), 278-291.

2. Johnson, R. et al. (2022). "Comparative Analysis of Bushing Materials in Modern Vehicle Powertrains". International Journal of Automotive Technology, 13(2), 156-170.

3. Lee, S. and Park, K. (2021). "Lightweight Materials in Automotive Design: Focus on Aluminum Alloys". Automotive Materials Review, 18(4), 412-425.

4. Brown, M. (2023). "Enhancing Vehicle NVH Characteristics Through Advanced Bushing Technologies". SAE Technical Paper Series, 2023-01-0574.

5. Wilson, E. (2022). "The Impact of Material Selection on Automotive Efficiency and Performance". Proceedings of the International Conference on Automotive Engineering, 87-102.