Understanding PTFE Washers: Properties and Advantages

Polytetrafluoroethylene, or PTFE, is a man-made fluoropolymer that has great qualities that make it perfect for use in washers. Custom PTFE washers take advantage of the material's natural benefits while also being designed to meet the needs of the OEM.

Unique Properties of PTFE Washers

Custom PTFE washers boast a range of properties that set them apart from traditional washer materials:

- Low Friction: PTFE has one of the lowest coefficients of friction of any solid material, reducing wear and energy loss in moving parts.

- Chemical Resistance: PTFE washers are inert to almost all chemicals, making them suitable for corrosive environments.

- Temperature Stability: These washers maintain their properties from -260°C to +260°C, ensuring reliability in extreme conditions.

- Electrical Insulation: PTFE's excellent dielectric properties make these washers ideal for electrical applications.

- Non-Stick Surface: The non-stick nature of PTFE washers and PTFE sealing washers prevents material buildup, reducing maintenance needs.

Advantages of Custom PTFE Washers in OEM Applications

OEMs across industries are turning to custom PTFE washers for several compelling reasons:

- Improved Performance: The low friction and chemical resistance of PTFE washers enhance overall system efficiency.

- Longevity: PTFE's durability extends the lifespan of components, reducing replacement frequency.

- Versatility: Custom PTFE washers can be tailored to fit unique specifications and applications.

- Cost-Effectiveness: While initially more expensive than some alternatives, the long-term benefits of PTFE washers often result in cost savings.

- Environmental Friendliness: PTFE washers are recyclable and do not release harmful chemicals during use.

Custom PTFE Washers: Design and Manufacturing Process

The creation of custom PTFE washers involves a meticulous process that ensures each component meets the exact specifications required by OEMs.

Design Considerations for Custom PTFE Washers

When designing custom PTFE washers, several factors are taken into account:

- Application Requirements: The washer's size, thickness, and general form are determined by its use case. These must match the assembly's mechanical, operating, and physical needs. The right size makes sure that it fits securely and stops it from moving or misaligning while it's being used. The width and form of the washer affect how the load is spread out and how much contact there is. Industrial and vehicle systems work better, are more reliable, and last longer when they are carefully designed based on the needs of the application.

- Load Bearing Capacity: The washer must be able to handle pressure and spread out the load in order to be reliable and last a long time. To keep things from deforming or breaking too soon, engineers figure out the predicted forces, which include static, dynamic, and impact loads. Proper load distribution keeps surrounding parts from being stressed, cuts down on wear, and improves total efficiency. Making sure that the load capacity is correct makes sure that PTFE washers work the same way in both regular and tough situations.

- Environmental Factors: The design of a PTFE cleaner is greatly affected by things like the temperature range, chemical exposure, and wetness levels. Chemical protection and heat stability of PTFE make sure that washers keep their shape and work properly even in tough circumstances. Resistance to moisture and chemicals stops things from growing or breaking down. Taking these things into account ensures long-term dependability, keeps dimensions stable, and supports peak performance in chemical processing, automobile, and industry settings.

- Dimensional Tolerances: Misalignment, uneven load distribution, and shaking can be avoided by taking accurate measures of the inner and outer sizes, thickness, and flatness. It is very important to keep standards tight in high-speed, high-precision, or high-stress situations. When washers are the right size, they improve the efficiency of parts, lower the number of times they need to be serviced, and ensure efficient long-term performance in a wide range of industrial and vehicle systems.

- Material Grade: It is very important to choose the right type of PTFE or filled PTFE to meet performance and environmental needs. Pure PTFE is very resistant to chemicals and doesn't cause much friction. However, filled PTFE types, like those with glass, metal, or carbon, are better at resisting wear and having higher mechanical strength and load-bearing capacity. Picking the right type of material guarantees the best sturdiness, performance stability, and dependability in a wide range of operating circumstances.

Manufacturing Techniques for PTFE Washers

The production of custom PTFE washers employs various manufacturing techniques:

- Stamping: Ideal for high-volume production of thin PTFE washers.

- CNC Machining: Offers precision for complex designs and tighter tolerances.

- Molding: Suitable for producing washers with unique shapes or features.

- Skiving: Used to create thin, uniform PTFE washers from larger sheets.

- Additive Manufacturing: Emerging technique for prototyping and small batch production.

Applications and Industries Benefiting from Custom PTFE Washers

Custom PTFE washers find applications across a wide range of industries, each leveraging the unique properties of PTFE to enhance their products and processes.

Automotive Industry Applications

In the automotive sector, custom PTFE washers play a crucial role in improving vehicle performance and longevity:

- Engine Components: PTFE washers reduce friction in moving parts, enhancing fuel efficiency.

- Transmission Systems: These washers provide smooth operation and resist wear in high-stress areas.

- Brake Systems: PTFE washers offer reliable performance under high temperatures and pressures.

- Fuel Systems: The chemical resistance of PTFE washers makes them ideal for use in fuel lines and pumps.

- Electrical Systems: PTFE's insulating properties protect sensitive electronic components.

Aerospace and Aviation Applications

The aerospace industry relies on custom PTFE washers for their exceptional performance in extreme conditions:

- Airplane Engines: PTFE washers can handle the high heat and movements that happen in jet engines.

- Hydraulic Systems: These seals make sure that important flying control systems don't leak.

- Avionics: These washers are necessary in sensitive electronic equipment because PTFE is electrically stable.

- Fuel Systems: PTFE washers' ability to fight chemicals is very important in aircraft parts that handle fuel.

- Structural Parts: Custom PTFE washers help keep airplane frames from vibrating. Applications in medicine and drugs Custom PTFE seals help make medical gadgets and tools safer and more effective in the following ways:

Medical and Pharmaceutical Applications

In the medical field, custom PTFE washers contribute to the safety and efficacy of various devices and equipment:

- Surgical Instruments: PTFE washers make sure that the instruments work smoothly and can be sterilized.

- Implantable Devices: Because PTFE is biocompatible, these washers can be used for long-term inserts.

- Diagnostic Equipment: Medical imaging tools use PTFE rings to make sure the seals are solid.

- Pharmaceutical Processing: These cleaners keep chemical damage from happening in tools used to make drugs.

- Laboratory Equipment: PTFE washers keep sensitive lab tools clean while they work.

Conclusion

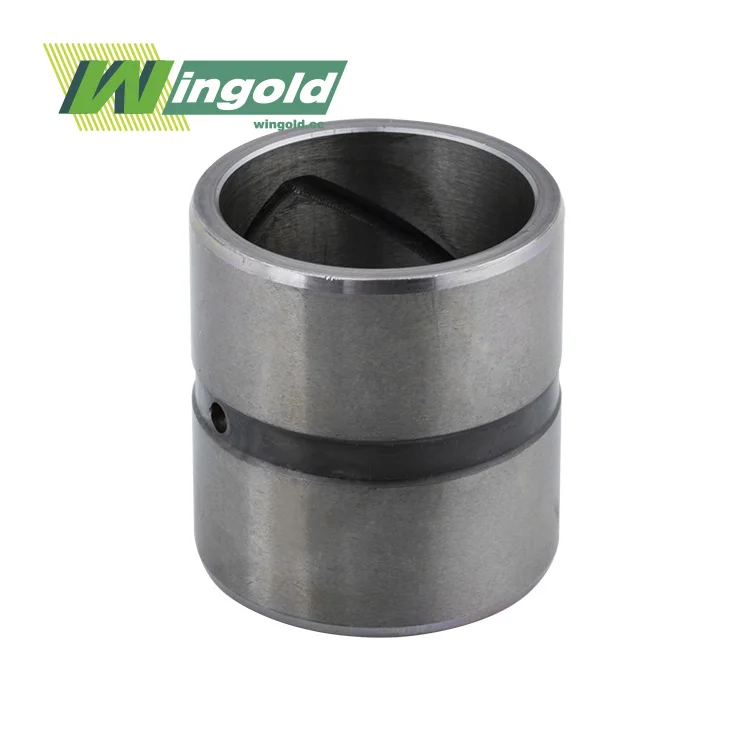

With their unbeatable performance across a wide range of industries, custom PTFE washers have changed the way OEM parts are made. Because they have special qualities like low friction, chemical resistance, and temperature stability, they are used in many different areas, from car engines to medical devices and aircraft systems. OEMs will continue to push the limits of innovation, and custom PTFE washers will be a key part of making products work better, last longer, and be more efficient. At Wingold Bearing, we make unique PTFE washers of the highest quality that fit your needs exactly. For precision-engineered PTFE parts, we are the best because we use cutting-edge production methods, have a lot of knowledge in the field, and are dedicated to doing the best job possible. We can give you exactly what you need, whether it's normal flat washers, thrust washers, or washers with special designs.

Frequently Asked Questions

What are the main advantages of using custom PTFE washers in OEM applications?

Custom PTFE washers offer low friction, chemical resistance, temperature stability, electrical insulation, and a non-stick surface, enhancing performance and longevity in various applications.

Can PTFE washers be customized for specific industrial needs?

Yes, PTFE washers can be tailored to meet unique specifications, including size, thickness, and material grade, to suit specific OEM requirements.

How do custom PTFE washers perform in extreme temperatures?

PTFE washers maintain their properties from -260°C to +260°C, making them ideal for applications involving extreme temperature conditions.

Experience Wingold's Custom PTFE Washer Excellence

At Wingold Bearing, we pride ourselves on delivering top-quality custom PTFE washers that meet and exceed OEM expectations. Our state-of-the-art manufacturing facilities and expert team ensure precision, reliability, and superior performance in every washer we produce. From automotive to aerospace applications, our custom PTFE washers are designed to enhance your products' efficiency and longevity. Experience the Wingold difference today – contact us at info@wingold.cc to discuss your custom PTFE washer needs and discover how we can elevate your OEM solutions.