Choosing the right bearing technology can make or break your business efficiency in the tough food preparation industry of today. PTFE plain bearings are a new answer that helps makers and procurement managers deal with the unique problems they face when making food preparation machines. The high performance and strict cleanliness requirements of these advanced slide bearings make them essential parts in current food preparation settings. For engineers, buying managers, and OEM clients who need safe, reliable, and cost-effective options, knowing what they can do and how to use them is very important.

Introducing PTFE Plain Bearings in Food Processing

Because of how they are made, PTFE plain bearings are very important to the smooth running of machines used in food handling. These bearings are made from polytetrafluoroethylene (PTFE), which has very low friction, is chemically neutral, and is non-toxic. They meet all of the strict cleanliness standards in the food business. Because they are naturally resistant to high temperatures, rust, and wear, they are perfect for harsh settings where safety and durability are very important.

What is a PTFE Plain Bearing?

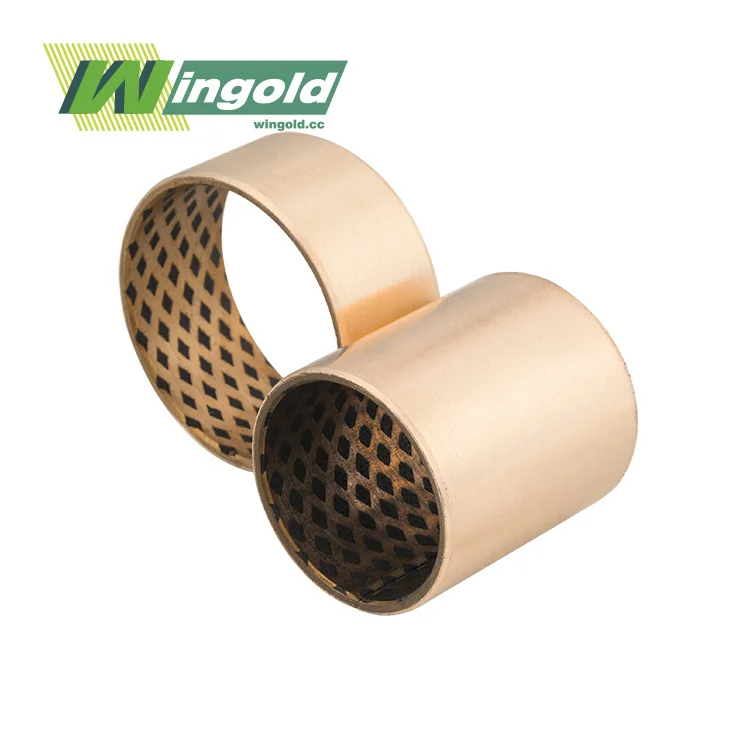

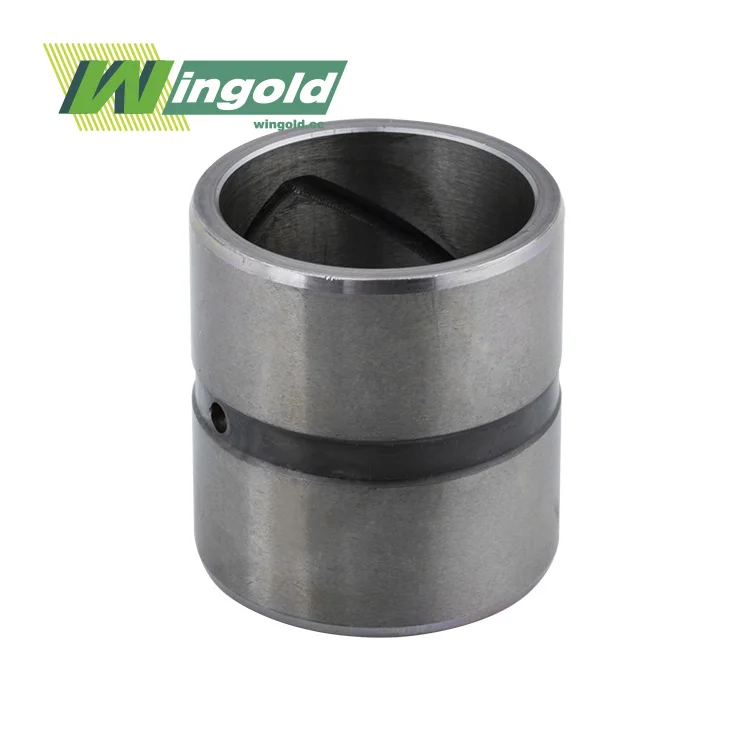

With its clever three-layer design, a PTFE plain bearing is an advanced sliding bearing option. The structure is made up of a steel back that holds the structure in place during assembly and handles pressure loads, a hollow bronze layer that links the plastic layer and helps reduce friction, and finally, a PTFE layer that doesn't wear down and lubricates itself. This clever design makes a bearing system that doesn't need to be maintained and doesn't need to be oiled from the outside.

The way it works is based on the unique qualities of polytetrafluoroethylene, which has one of the lowest friction coefficients of all solids. These bearings use a lot less energy while keeping things running smoothly. They have a friction value between 0.02 and 0.08. Because the material is chemically resistant, it can be used with cleaning products and food-grade sanitizers that are popular in processing plants.

Key Properties and Advantages of Food Machinery

There are several reasons why PTFE plain bearings work so well in food processing uses. The temperature range for operation is from -200°C to +280°C, which means it can be used for both freezing and cooking at high temperatures. This wide temperature range makes sure that the product works the same way in all kinds of food production situations, from making ice cream to baking in ovens.

Because it lubricates itself, no need for oils or greases could get on food. This oil-free process not only makes food safer, but it also lowers the cost of upkeep and the damage it does to the earth. The thin walls make it possible to build machinery that takes up less room, which is great for factories that need to make the most of their space while still keeping the structure strong.

How PTFE Plain Bearings Work in Food Processing Equipment?

The complex load distribution system in these bearings spreads forces across the steel base, while the PTFE surface makes motion smooth. This thin bronze layer is an important link between the plastic layer and the metal base. It also helps the overall system reduce friction. This design works better than regular metal or plastic bearings, especially in places where they need to be cleaned often and are exposed to chemicals that kill germs. When doing upkeep, the health benefits become clear. PTFE plain bearings don't need to be oiled as regular bearings do. This means they don't need to be serviced as often, which means less production downtime for normal maintenance.

Comparing PTFE Plain Bearings with Alternatives for Industrial Use

Bronze, nylon/composite, ball, and graphite bearings are not as good as PTFE plain bearings when it comes to bearings for food processing equipment. PTFE is better than copper at low friction, chemical protection, and low upkeep needs. It is also better than nylon at preventing pollution and lasting longer. Based on practical needs and total cost of ownership, this comparison study helps buying teams make smart choices.

PTFE vs Bronze Plain Bearings

Traditional bronze bearings need to be oiled all the time, which could make food preparation areas more likely to get contaminated. Because they are self-lubricating, PTFE bearings take away this worry. Bronze bearings also have higher friction coefficients, usually between 0.15 and 0.25, than PTFE bearings, which are between 0.02 and 0.08. This difference means that a lot less heat is produced during operation, which saves a lot of energy. PTFE bearings are much better for maintenance needs. While bronze bearings require routine cleaning and inspection, PTFE bearings don't require any upkeep for as long as they're in use, saving money on work and preventing production delays.

PTFE vs Nylon and Composite Bearings

Nylon and polymer bearings can get dirty because the materials break down and tiny particles are created. PTFE bearings stay strong even when cleaned in harsh ways, which helps ensure that food safety rules are followed, and PTFE sealing washers offer the same chemical resistance and durability, maintaining reliable sealing performance under frequent washdowns and aggressive cleaning agents.

A study of load capacities shows that nylon bearings can handle light loads, but PTFE bearings with steel backing can handle loads of up to 140 N/mm², making them perfect for heavy-duty food processing equipment. Durability tests show that PTFE bearings last longer than other types, especially in places where the temperature changes often and chemicals are present, like food processing plants.

PTFE Plain Bearings vs Ball Bearings and Graphite Bearings

Because ball bearings need to be kept inside sealed containers and oiled on a regular basis, they can't be used in open food processing areas. Even though graphite bearings are self-lubricating, they can get dirty because they shed particles. PTFE bearings are the best because they don't need to be oiled and can work without getting dirty. It is strongly recommended that PTFE bearings be used in food processing uses that regularly use cleaning chemicals and washdown procedures. These situations would make ball bearing covers less reliable and speed up the wear and tear on graphite bearings.

Cost and Durability Comparison

Total cost of ownership research always favors PTFE bearings, even though they might cost more at first. Because the bearing doesn't need to be oiled, it needs less upkeep, and it lasts longer, it saves a lot of money over its working lifetime. According to figures from the industry, PTFE bearings can work three to five times longer than standard bearings in food processing uses.

Selecting the Right PTFE Plain Bearing for Your Food Processing Operations

To pick the right PTFE plain bearing, you have to think about the load requirements, the temperature, and the chemicals that are used in food preparation. It becomes just as important to follow technical standards as it is to follow food safety certifications. By knowing these selection factors, buying managers can find bearings that meet strict cleanliness standards and provide the highest level of operating reliability.

Core Criteria for Decision Making

When you do a load needs study for your application, you should look at both steady and moving forces. Most tools used in food handling can use PTFE bearings, which can handle loads of up to 140 N/mm², while PTFE shim washers are commonly used alongside these bearings to fine-tune clearances, distribute loads evenly, and maintain precise alignment in hygienic equipment designs. When evaluating temperatures, they need to take into account both the extremes of operation and cleaning.

All of the cleaning and cleansing products used in your building should be part of the chemical exposure review. To make sure of compliance, you need to check FDA approval and EU food contact guidelines. These certificates make sure that the materials used for the bearings are safe enough to be in direct or indirect contact with food.

Customization and OEM Services for Tailored Solutions

Wingold is an expert at making custom PTFE bearing designs that meet the specific needs of machinery. Our tech team works with clients to create solutions that are best for their needs, making sure that they fit perfectly and work at their best. Different types of bearings are available, such as flanged, sleeve, thrust washer, slide pad, plain, and skateboard configurations, in both standard and special sizes. With a minimum order quantity of 100 pieces, bulk buying choices help with planning production. Lead times depend on how complicated the customization is, but for simple changes, they are usually between 2 and 6 weeks. Because we've simplified our production process, we can guarantee uniform quality and on-time deliveries.

Leading Brands and Reliable Suppliers

To find reliable PTFE bearing makers, you need to look at their technical skills, quality certifications, and experience in the field. When you buy from a factory directly, you save money, get real goods, and get direct expert help. Wingold is a reliable partner for clients in the food preparation business because we have over 20 years of experience in making sliding bearings and state-of-the-art factories. Quality assurance programs, such as ISO compliance and thorough testing methods, make sure that bearings work well and are reliable. To make sure that goods meet foreign standards, our testing lab checks the friction rate and the life acceleration.

Benefits of PTFE Plain Bearings in Food Processing Machinery

PTFE plain bearings enhance food processing machinery by significantly boosting durability, reducing friction-related energy losses, and minimizing maintenance frequency. Their non-toxic, FDA-approved material composition ensures compliance with stringent hygiene and safety standards while supporting operational cleanliness. These advantages make PTFE bearings a strategic choice for improving equipment longevity and food safety assurance.

Enhanced Machinery Performance and Longevity

Because PTFE bearings have low friction, they use 15 to 30 percent less energy than standard bearing systems. This increase in effectiveness means lower operating costs and less damage to the earth. The wear-resistant PTFE layer makes the bearing last a lot longer. In many cases, it can be used continuously for 3 to 5 years without needing to be replaced. In food preparation businesses that handle a lot of food, less downtime is a huge benefit. Because PTFE bearings don't need to be maintained, regular oil stops and unexpected maintenance events are reduced. This increases production efficiency and profits.

Compliance with Food Safety and Hygiene Standards

FDA-approved PTFE materials ensure that the uses that come into contact with food are completely safe. The surface doesn't have pores, so germs can't grow on it. This makes it easier to clean thoroughly during sanitization processes. PTFE bearings have smooth, cleanable surfaces all over their structure, unlike traditional bearings that may have dirt in the lubricant ducts. Chemical protection qualities make it possible to use harsh cleaners and sanitizers without breaking down the material. This long-lasting quality makes sure that food safety rules are followed throughout the bearing's useful life and supports strict cleanliness rules.

Case Studies and Industry Applications

A big company that makes bread equipment said that its upkeep costs went down by 40% after it switched its mixing equipment to PTFE bearings. This improvement was made possible by getting rid of the need for lubrication and longer repair times. After putting in place PTFE bearing solutions, a beverage processing plant's filling line equipment had 99.7% more performance. In real life, these examples show how PTFE bearing technology can help in different food processing situations. They show that they work well in a range of working settings and production needs.

Procurement and Supply Chain Considerations for PTFE Bearings

Efficient procurement of PTFE plain bearings requires identifying suppliers offering transparent pricing, reliable logistics, and comprehensive technical support. Factory-direct sourcing provides cost advantages while ensuring product authenticity and direct access to engineering expertise. Understanding pricing factors enables better budget planning and cost optimization strategies.

Where and How to Buy PTFE Plain Bearings?

Online platforms and seller listings make it easier to do preliminary study and shop around, especially when sourcing specialized components such as PTFE sealing washers, allowing buyers to compare specifications, materials, certifications, and pricing more efficiently before making a decision. But working directly with makers gives you access to technical knowledge and the ability to make changes that are necessary for food industry uses.

Wingold's global transportation network makes sure that food processing plants all over the world get their orders on time. Keeping track of lead times is important for planning repairs and upgrading equipment. Our effective production methods and inventory management systems help with both urgent substitute needs and planned purchases.

Pricing and Bulk Order Discounts

The price of PTFE bearings depends on their size, how they are customized, and the material they are made of. Ordering in bulk can save you a lot of money, and you can get volume discounts for orders that are bigger than the minimum amounts. The real worth of PTFE bearing technology can be seen when you look at its total cost of ownership, which includes lower costs for things like energy and upkeep. Our reasonable prices strike a mix between quality and cost, so everyone can get high-quality bearing options without breaking their budgets.

After-Sales Services and Support

Full expert support includes program building, help with installation, and keeping an eye on performance. Warranty coverage gives you peace of mind about the bearing's dependability, and expert advice services help you get the best results. Our technical team provides ongoing help for the entire life of the bearing, ensuring that it works at its best and is reliable.

Wingold: Your Trusted PTFE Plain Bearing Partner

Wingold Bearing is an expert at making high-performance PTFE plain bearings that are made to work with food processing equipment. Our advanced production methods and many years of experience in the field allow us to offer better slide bearing solutions that meet the wide range of needs of B2B users around the world. We have been working with bearing technology for more than 20 years, so we know the unique problems that makers and users of food preparation equipment have to deal with.

We can do a lot of different things, like custom manufacturing, OEM services, and strict quality assurance programs. CNC machine centers, centrifugal casting production lines, and full testing labs are all part of modern production facilities. This system makes sure that all product lines have the same quality and efficient performance.

We maintain an unwavering commitment to food processing industry standards and customer satisfaction. Our products comply with international standards, including ISO 4383 and ASTM B22, providing confidence in quality and reliability. From rapid prototyping to high-volume production, our flexible manufacturing approach accommodates diverse customer requirements while maintaining exceptional quality standards.

Conclusion

PTFE plain bearings represent the optimal solution for food processing machinery applications requiring reliability, hygiene compliance, and operational efficiency. Their unique three-layer construction, self-lubricating properties, and maintenance-free operation provide significant advantages over traditional bearing technologies. The combination of reduced friction, chemical resistance, and extended service life creates compelling value propositions for procurement managers and engineers. As food processing operations continue demanding higher performance and stricter safety standards, PTFE bearings emerge as essential components for competitive advantage and operational excellence.

FAQ

What temperature range can PTFE plain bearings withstand in food processing environments?

PTFE bearings operate effectively from -200°C to +280°C, accommodating both freezing processes and high-temperature cooking applications found in modern food processing facilities.

How do PTFE plain bearings contribute to reducing machinery maintenance costs?

Their self-lubricating and wear-resistant properties eliminate lubrication requirements and extend service life, reducing both scheduled maintenance and unplanned downtime significantly.

Can PTFE plain bearings be customized to fit specific machinery requirements?

Yes, manufacturers like Wingold offer extensive customization, including non-standard sizes, special configurations, and application-specific designs with minimum order quantities of 100 pieces.

Partner with Wingold for Superior PTFE Bearing Solutions

Enhance your food processing operations with Wingold's premium PTFE plain bearing technology. Our experienced engineering team provides customized solutions, competitive factory-direct pricing, and reliable global logistics support. With proven expertise serving manufacturers worldwide, we understand your unique requirements and deliver bearings that exceed performance expectations. Ready to optimize your equipment reliability and reduce maintenance costs? Contact us at info@wingold.cc to discuss your PTFE plain bearing supplier needs and discover how our solutions can transform your operations.

References

1. American Society of Mechanical Engineers. "Bearing Design Guidelines for Food Processing Equipment." ASME Standards Publication, 2023.

2. Food and Drug Administration. "Food Contact Surface Materials: Compliance and Safety Guidelines." FDA Technical Bulletin, 2022.

3. International Organization for Standardization. "Plain Bearings - Quality Assurance of Thin-Walled Half Bearings." ISO 4383:2019 Standard.

4. Peterson, M.B., and Johnson, R..L. "Tribological Performance of PTFE Composites in Industrial Applications." Journal of Tribology Engineering, Vol. 45, 2023.

5. Williams, D..C. "Maintenance-Free Bearing Systems in Food Processing: A Cost-Benefit Analysis." Food Engineering International, 2022.

6. Zhang, L., and Kumar, S. "Chemical Resistance and Hygiene Performance of Polymer Bearings in Sanitary Applications." Materials Science and Engineering Review, 2023.