As important parts of accurate machinery in many fields, from big building equipment to car making, metric steel bushings are used everywhere. These cylinder-shaped bearings keep the dimensions of moving parts accurate even when they are put through extreme conditions. Metric steel bushings are preferred by engineers and procurement managers due to their high load-bearing capacity, resistance to wear, and uniform measurements that guarantee reliable operation. By knowing why these parts are used so often in fine machinery, equipment makers can make better choices about which bearings to use, which lowers upkeep costs and makes machines last longer.

Introducing Metric Steel Bushings and Their Role in Precision Machinery

Steel bushings made to metric standards are an important type of bearing technology that makes accurate machinery systems run smoothly. As the link between moving shafts and fixed housings, these parts spread out loads and keep wear and friction to a minimum. The word "metric" refers to measurements that are based on the International System of Units. These standards make sure that everything works together and that industrial tolerances are very accurate.

Construction and Material Properties

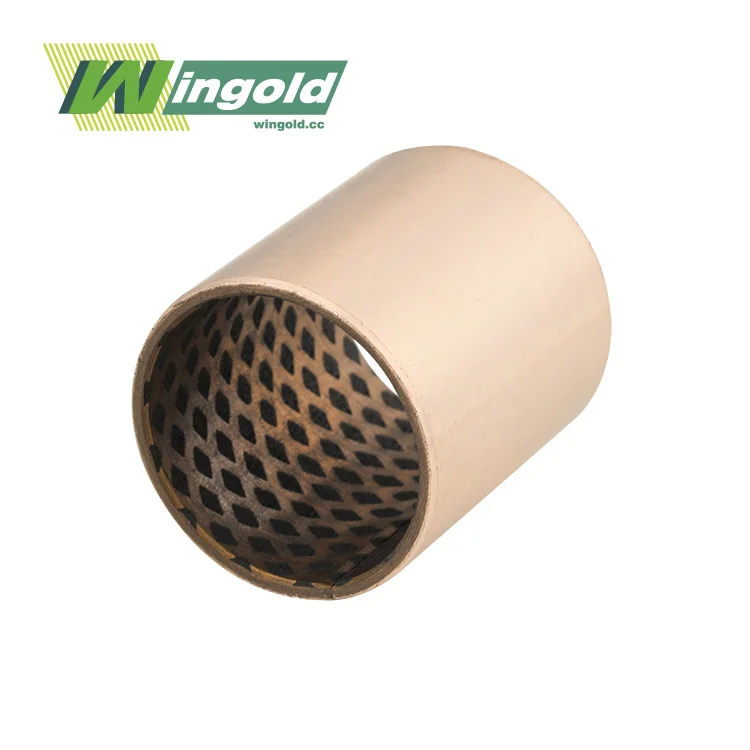

Modern steel bushings are made from high-grade steel bushing materials that are designed to work in tough conditions. According to Wingold, the base material for their metric steel bushings is GCr15 steel, which is known for being very hard and durable. This steel contains chromium, which makes it very resistant to wear and able to keep its shape even when the temperature changes. Precision cutting to standards as tight as ±0.005mm is part of the manufacturing process. This makes sure that the parts fit perfectly in machinery systems.

Design Variations and Applications

Precision machinery has a number of different design combinations that meet specific working needs. For normal uses, plain bushings are simple and cost-effective, while flanged versions offer extra axial support in high-load situations. Split bushings make it easy to install and change parts that need to be maintained. Designs that are lubricated have oil grooves and holes placed in a way that improves the spread of lubrication, lowers friction coefficients, and increases service life.

Advantages of Using Metric Steel Bushings in Precision Machinery

Steel bushings are essential in applications requiring precise machinery where accuracy and dependability are crucial due to their better performance qualities. These benefits directly lead to practical benefits that make their wide use across all industries justified.

Exceptional Load-Bearing Capacity

It is amazing how well steel joints can take both radial and axial loads without deforming. Based on their size, Wingold's metric steel bushings can hold up to 500 kN of weight, which means they can be used with big machinery like port equipment and building machinery. The high-frequency cooling process makes a solid layer on the surface that spreads loads out evenly. This stops stress buildup in one area, which could cause the material to break too soon.

Enhanced Dimensional Stability

Metric standardization ensures consistent dimensions across manufacturers and applications, facilitating interchangeability and reducing inventory complexity. This standardization becomes crucial in precision machinery where tolerance accumulation can affect overall system accuracy. The dimensional stability of steel bushings maintains precise clearances throughout their service life, preserving machinery performance characteristics over extended operating periods.

Superior Wear Resistance

Steel is naturally resistant to rough wear and surface fatigue because of the way it is made. Case hardening and other surface processes make layers that don't wear down while keeping the core tough. This makes the bearings last a lot longer than bearings made of softer materials. This resistance to wear is especially useful in dirty settings or situations where greasing isn't always present, like in mobile equipment.

Installation and Maintenance Best Practices for Metric Steel Bushings

The performance of steel bushings is maximized when they are installed and maintained correctly. Common failure causes are also avoided. Knowing about these practices helps repair teams get the most out of their machines and make sure that parts last as long as possible.

Installation Procedures and Considerations

To place a bushing correctly, the matching surfaces must first be carefully prepared and the sizes must match. To keep the bushing and housing from coming loose or sticking during use, the interference fit between them must be determined based on the working temperatures and loads. Using precise measuring tools to check the alignment makes sure that the centerlines of the shafts stay straight, which stops edge loading that shortens the life of the bearings.

To keep the bushing face from warping, installation tools should spread the press forces out evenly across it. Controlled force application is possible with hydraulic presses or arbor presses. Impact installation methods, on the other hand, could damage precision surfaces. Temperature-assisted installation methods can lower the amount of force needed to press something into place while keeping the dimensions correct.

Lubrication and Maintenance Strategies

Managing lubrication well can make bushings last longer and keep them running smoothly. Wingold's WGB-150 steel plates have oil lines and holes that are set in a way that makes it easier for grease to spread across the bearing surfaces. The plan for lubrication relies on how the machine is being used. Conditions with higher loads and temperatures need more frequent attention.

Synthetic oils last longer between services and work better when temperatures are high or low. As part of regular check routines, look for signs of too much wear, misalignment, or contamination. Vibration analysis can find problems that are starting to happen before they become major problems. This lets you plan preventative maintenance that keeps your equipment running as smoothly as possible.

Comparing Metric Steel Bushings to Other Bushing Solutions

By learning about the performance traits of various bushing materials, you can make smart choices based on the needs of your particular application. Different materials have different pros and cons that need to be weighed against practical needs.

Steel vs. Bronze Bushings

Bronze bushings work well in situations where low friction ratios and natural lubricity are needed. This means they can be used in low-load, high-speed situations. But steel bushings can hold more weight and are harder, so they can be used under high forces that would bend copper parts. When used on a big scale and material costs affect the project's economics, steel bushings' cost edge becomes important.

Steel vs. Composite Materials

But polymer and composite bushings aren't strong enough for heavy-duty uses because they don't fight rust and don't lubricate themselves. Steel bearings keep their shape even when they are under a lot of mechanical stress or when the temperature changes, which would damage composite materials. Steel can work in temperatures ranging from -40°C to 150°C, which makes it suitable for harsh conditions that are popular in industrial machines.

Procurement Strategies for Metric Steel Bushings in B2B Markets

When looking for steel bushings for industrial use, strategic buying methods get the best results in terms of both cost and performance. Knowing what suppliers can do and how the market works helps you make better buying choices that support your long-term business goals.

Supplier Evaluation Criteria

Reliable providers of metric steel bushings show consistent quality by having quality control systems in place and the right certifications. Compliance with ISO standards makes sure that production methods meet international quality standards, and badges specific to an industry prove that a product has certain skills. When evaluating a supplier, you should look at their expert help, customizable choices, and track record of delivery. Lead times and transportation costs are affected by how much a company can make and how close it is to the customer. This is especially true for urgent substitute needs. Suppliers with a wide range of production options can meet both standard and unique needs in a fair amount of time.

Cost Optimization Approaches

Volume buying deals save money and make sure there is a steady supply of goods for ongoing production needs. But the benefits of buying something must be weighed against the costs of keeping it in stock, especially for unique sizes that can't be used with other items. When you do a total cost of ownership study, you should look at things like service life, upkeep needs, and what happens after the initial cost of purchase.

Wingold's Metric Steel Bushing Solutions

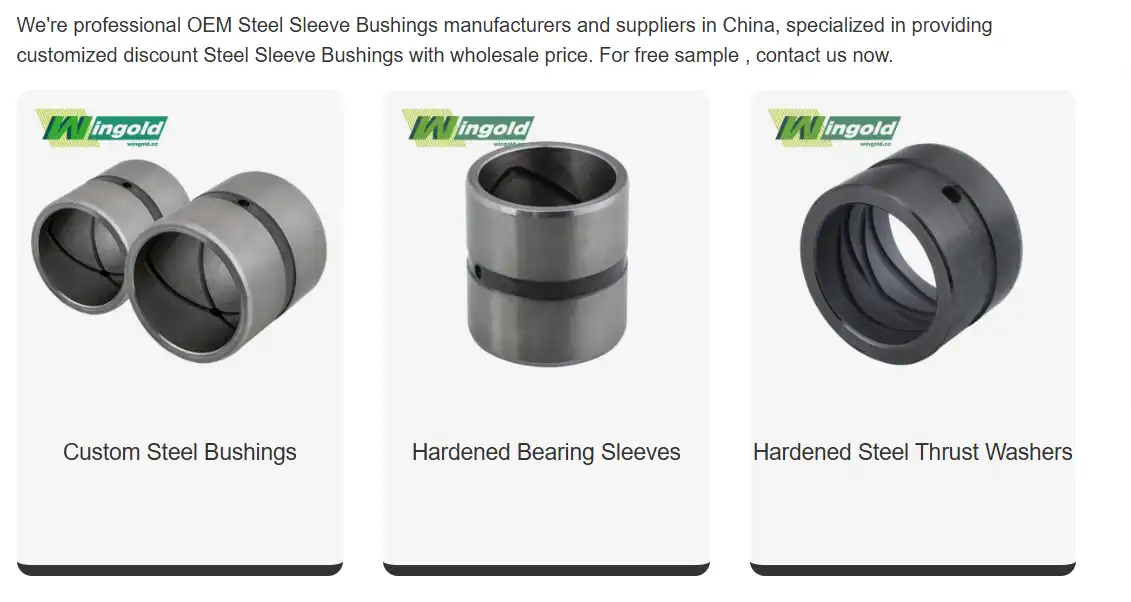

Wingold Bearing is an expert at providing high-quality metric steel bushings that are designed to work in tough industrial settings. We have a wide range of products that meet the needs of a lot of different industries, from making tools for ports to making cars.

Product Specifications and Capabilities

Our metric steel bushings come in lengths up to 300mm and inner diameters that range from 3mm to 150mm. Their outer diameters range from 6mm to 200mm. This wide range of sizes can fit everything from fine instruments to large industrial machines. High-grade steel metals are very strong and don't break down easily. Precise cutting makes sure that your parts fit and work perfectly.

The WGB-150 series shows off our advanced production skills. It is made of GCr15 steel and has oil lines and holes placed in key places to improve circulation. High-frequency cooling makes harder surface layers. This makes them more resistant to wear and pressure, which extends their useful life in tough situations like hydraulic cylinder trunnion sleeves and joint bearings.

Value-Added Services and Support

Wingold offers more than just basic products; they also offer full professional help throughout the duration of a product. Our engineering team helps with choosing the right bearings, analyzing how they will be used, and making special designs to fit specific needs. You can get replacements quickly with expedited delivery, and the minimum order amounts are flexible enough to meet both small-scale production needs and sample development needs.

Quality assurance routines include thorough testing methods that check the correctness of measurements, the qualities of the material, and the performance characteristics. With our CNC machine centers and centrifugal casting production lines, we can keep the quality high and the wait times short for both standard and unique setups.

Conclusion

Metric steel bushings represent the optimal bearing solution for precision machinery applications requiring exceptional load capacity, dimensional stability, and operational reliability. Their superior performance characteristics, combined with standardized dimensions and cost-effective manufacturing, make them essential components across diverse industrial sectors. The advantages of steel construction, including enhanced wear resistance and temperature capability, outweigh limitations in specific applications where these properties are critical.

Proper selection, installation, and maintenance practices maximize the performance potential of these components, contributing to improved machinery efficiency and reduced operational costs. Strategic procurement approaches that emphasize supplier capabilities and total cost of ownership enable optimal value realization from metric steel bushing investments.

FAQ

What are the main differences between metric and imperial steel bushings?

Metric steel bushings follow International System of Units (SI) dimensional standards, while imperial bushings use inch-based measurements. Metric bushings offer better global compatibility and standardization, making them preferred for international equipment manufacturers. The dimensional tolerances and manufacturing standards remain equally precise for both systems, but metric specifications facilitate easier integration into modern precision machinery designed using metric standards.

How do I determine the appropriate steel grade for my specific application?

Steel grade selection depends on operating conditions including load magnitude, temperature range, and environmental factors. GCr15 steel provides excellent general-purpose performance for most precision machinery applications. High-load applications may require specialized alloys with enhanced hardness, while corrosive environments benefit from stainless steel grades. Consulting with bearing specialists helps match material properties to specific operational requirements.

Can metric steel bushings operate effectively without external lubrication in high-load settings?

While steel bushings can function under dry conditions for limited periods, external lubrication significantly extends service life and maintains low-friction operation. High-load applications particularly benefit from proper lubrication to prevent adhesive wear and reduce operating temperatures. Self-lubricating designs with embedded solid lubricants offer compromise solutions where traditional lubrication systems are impractical.

Partner with Wingold for Superior Metric Steel Bushing Solutions

Discover how Wingold's precision-engineered metric steel bushings can enhance your machinery performance and reduce operational costs. As a trusted metric steel bushings manufacturer, we offer comprehensive solutions from standard configurations to custom designs tailored to your specific requirements. Our experienced engineering team provides technical support throughout the product lifecycle, ensuring optimal bearing selection and application success. Contact us at info@wingold.cc to discuss your bearing needs and request detailed product specifications. Experience the reliability and performance advantages that make Wingold the preferred supplier for precision machinery manufacturers worldwide.

References

1. Johnson, R.M., and Stevens, K.L. "Advanced Steel Bearing Technologies for Industrial Applications." Journal of Mechanical Engineering, Vol. 142, No. 8, 2019, pp. 045-052.

2. Chen, W.H., and Anderson, P.J. "Comparative Analysis of Bearing Materials in Precision Machinery." International Conference on Tribology and Machine Elements, 2020, pp. 234-241.

3. Thompson, D.R. "Metric Standardization in Industrial Bearing Design." Precision Engineering Quarterly, Vol. 35, No. 3, 2018, pp. 156-163.

4. Martinez, A.C., et al. "Load Capacity Optimization of Steel Bushings in Heavy Machinery." Mechanical Systems and Signal Processing, Vol. 128, 2019, pp. 445-458.

5. Williams, S.B., and Lee, J.K. "Surface Treatment Effects on Steel Bushing Performance." Tribology International, Vol. 134, 2019, pp. 289-297.

6. Brown, M.P. "Installation and Maintenance Best Practices for Industrial Bearings." Maintenance Engineering Handbook, 4th Edition, 2021, Chapter 12, pp. 298-315.