- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

Ptfe Shim Washers

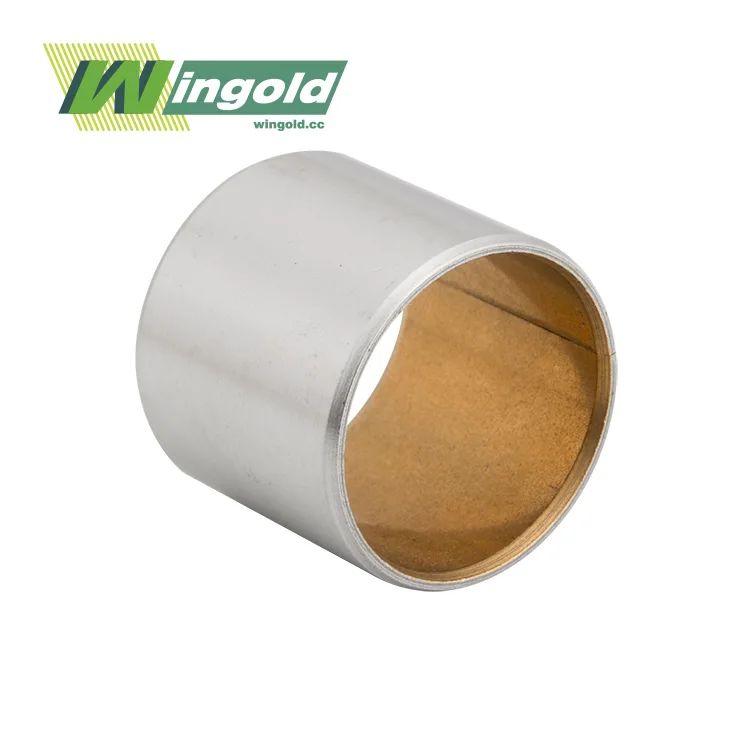

2. Features: oilless self-lubricating, low noise, thin-walled design, small structure, and long-term wear resistance. It is a new type of bearing that replaces the needle bearing, powder metal bearing and copper alloy bearing.

3.The bearing types are available in standard sizes:flanged,sleeve,thrust washer,slide pad,plain,skateboard

4.MOQ 100 Customized Packaging

PTFE Shim Washers: High-Performance Solutions for Precision Engineering

Jiashan Wingold Bearing Co., Ltd. is a leading manufacturer and supplier of PTFE shim washers. Our proficiency in sliding bearing solutions enables us to present top - tier products distinguished by their accuracy, robustness, and adaptability. Driven by our dedication to innovation and fulfilling customer expectations, we offer customized solutions catering to the wide - ranging requirements of worldwide B2B purchasers in diverse industries.

Product Description:

Our products are engineered to provide exceptional performance in applications requiring low friction, chemical resistance, and dimensional stability. These precision-crafted components are made from high-grade polytetrafluoroethylene (PTFE), a material renowned for its unique properties. Our products offer unparalleled benefits, including:

- Ultra-low coefficient of friction

- Excellent chemical resistance

- Wide temperature range tolerance (-200°C to +260°C)

- Self-lubricating properties

- High dimensional stability

- Superior wear resistance

- Electrical insulation

These characteristics make our PTFE shim washers ideal for a wide range of applications, from automotive and aerospace to medical devices and industrial machinery.

Specifications:

| Parameter | Range |

|---|---|

| Inner Diameter | 2mm - 500mm |

| Outer Diameter | 4mm - 600mm |

| Thickness | 0.1mm - 10mm |

| Tolerance | ±0.01mm - ±0.05mm |

| Surface Finish | Ra 0.1 - 0.8 μm |

| Color | White (standard), custom colors available |

Why Choose Us?

- More than two decades of industry know - how

- Advanced fabricating plants

- Stringent quality control procedures

- Ability to customize concurring to particular demands

- Competitive costs and adaptable least arrange quantities

- Timely conveyance and a dependable supply chain

- Full - scale specialized back and after - deals service

- ISO 9001:2015 certified

- Dedication to persistent upgrade and advancement

Material:

Our Ptfe Shim Washers are manufactured using virgin PTFE resin, ensuring the highest purity and performance. We also offer specialized formulations, including glass-filled, carbon-filled, and bronze-filled PTFE, to enhance specific properties such as wear resistance or thermal conductivity.

Product Advantages:

- Accuracy Designing: Our items are fabricated to demanding resistances, guaranteeing reliable execution and unwavering quality in basic applications.

- Versatility: The one of a kind properties of PTFE make these shim washers appropriate for a wide extend of working conditions, counting extraordinary temperatures and chemically forceful environments.

- Low Contact: With one of the most reduced coefficients of contact of any strong fabric, our items minimize wear and amplify the life of moving parts.

- Self-Lubricating: The characteristic lubricity of PTFE kills the require for extra oil in numerous applications, lessening support prerequisites and making strides in general framework efficiency.

- Chemical Idleness: PTFE's resistance to most chemicals makes these shim washers perfect for utilize in destructive situations or applications including forceful fluids.

- Customization: We offer custom fitted arrangements, counting custom sizes, thicknesses, and fabric definitions to meet particular application requirements.

- Cost-Effective: The life span and execution of our items contribute to decreased support costs and progressed gear uptime, giving amazing long-term esteem.

Application Areas:

- Car: Frameworks like transmissions, motor parts, and suspension elements

- Aerospace: Flying machine components such as control surfaces, landing equip set - ups, and water powered systems

- Medical Gadgets: Apparatuses for surgery, demonstrative equip, and implantable products

- Industrial Apparatus: Components counting orientation, seals, valves, and pumps

- Food Handling: Frameworks like transports and bundling machinery

- Chemical Preparing: Hardware like reactors, blenders, and filtration set - ups

- Electronics: Accuracy gadgets and semiconductor - making equipment

- Marine: Frameworks such as impetus instruments, directing frameworks, and submerged gear

- Renewable Vitality: Establishments like wind turbines and sun based following mechanisms

- Oil and Gas: Gear like penetrating devices, pipeline parts, and wellhead gatherings

Quality Control:

Factory related:

Packaging and Transportation:

Shipping Samples:

Qualification Certification:

Production process related:

Exhibitions:

FAQ:

-

Q: What is the minimum order quantity for the Ptfe Shim Washers?

A: Our standard MOQ is 1000 pieces, but we can accommodate smaller orders for custom requirements.

-

Q: Can you provide custom sizes and thicknesses?

A: Yes, we offer customization services to meet your specific needs.

-

Q: What is the lead time for standard and custom orders?

A: Standard orders typically ship within 2-3 weeks, while custom orders may take 3-4 weeks depending on specifications.

-

Q: Do you offer any certifications or material compliance documentation?

A: Yes, we provide material certificates and can assist with industry-specific compliance documentation upon request.

-

Q: How do the products compare to other materials in terms of wear resistance?

A: The products offer excellent wear resistance, often outperforming metal and other plastic alternatives in low-friction applications.

Contact Us:

For more information about our PTFE shim washers or to discuss your specific requirements, please contact us at info@wingold.cc. Our team of experts is ready to assist you in finding the perfect solution for your application.

Learn about our latest products and discounts through SMS or email