- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

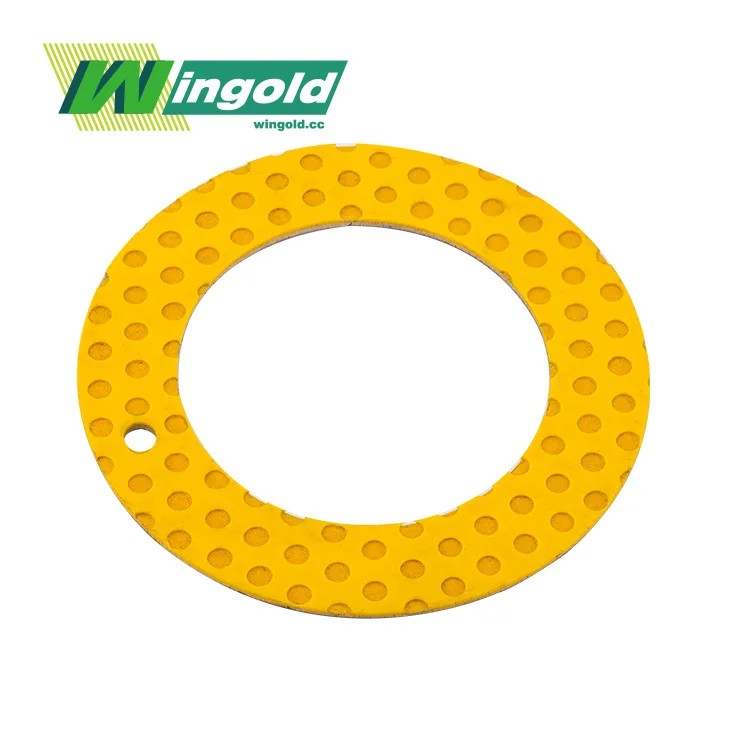

Bimetallic Bushing Sleeve

Jiashan Wingold Bearing Co., Ltd.: Your Trusted Bimetallic Bushing Sleeve Manufacturer

As a leading Bimetallic Bushing Sleeve manufacturer and supplier, Jiashan Wingold Bearing Co., Ltd. offers superior quality, innovative design, and exceptional customer service. Our advanced manufacturing techniques and stringent quality control ensure that our products meet the highest industry standards, providing reliable performance and long-lasting durability for your applications.

Bimetallic Bushing Sleeve Description:

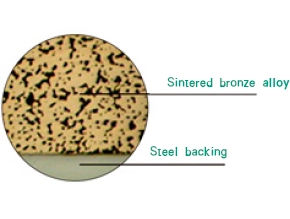

Our products are engineered to excel in demanding environments, combining the strength of steel with the low-friction properties of specialized alloys. These precision-crafted components feature a steel backing for structural integrity and a thin layer of high-performance bearing material, typically bronze or aluminum alloy. This unique construction provides an ideal balance of load-bearing capacity, wear resistance, and thermal conductivity.

The bimetallic design allows for excellent heat dissipation, reducing the risk of thermal expansion and ensuring consistent performance under varying operating conditions. Our bushing sleeves are suitable for both dry and lubricated applications, offering versatility across multiple industries. With customizable dimensions and material compositions, we can tailor our products to meet your specific requirements, ensuring optimal fit and function in your equipment.

Specifications:

| Parameter | Range |

|---|---|

| Inner Diameter | 10mm - 500mm |

| Outer Diameter | 12mm - 550mm |

| Length | 10mm - 1000mm |

| Wall Thickness | 1mm - 25mm |

| Operating Temperature | -40°C to 280°C |

| Load Capacity | Up to 250 MPa |

Why Choose Us?

- Over 20 years of industry experience

- State-of-the-art manufacturing facilities

- Customization capabilities to meet unique requirements

- Rigorous quality control and testing procedures

- Competitive pricing without compromising on quality

- Fast turnaround times and reliable delivery

- Comprehensive technical support and after-sales service

Material:

Our bimetallic bushing sleeves are crafted using carefully selected materials to ensure optimal performance:

- Steel backing: SAE 1010, SAE 1020, or stainless steel for structural integrity

- Bearing layer: Bronze alloys (CuSn8, CuPb10Sn10), aluminum alloys (AlSn20, AlSn40), or other specialized materials based on application requirements

Product Advantages:

- Superior Load Capacity: The steel backing provides excellent structural support, allowing our products to withstand high loads without deformation. This makes them ideal for heavy-duty applications in industrial machinery and automotive systems.

- Enhanced Wear Resistance: The carefully selected bearing layer materials offer exceptional wear resistance, significantly extending the lifespan of your equipment and reducing maintenance costs. This is particularly beneficial in high-friction environments or applications with frequent start-stop cycles.

- Excellent Thermal Management: The bimetallic construction facilitates efficient heat dissipation, preventing overheating and maintaining consistent performance even under demanding operating conditions. This thermal stability ensures reliable operation and reduced risk of premature failure.

- Self-Lubricating Properties: Many of our products incorporate materials with self-lubricating properties, reducing the need for frequent lubrication and minimizing maintenance requirements. This feature is especially valuable in hard-to-reach areas or applications where regular lubrication is impractical.

- Corrosion Resistance: Depending on the chosen materials, our products can offer excellent corrosion resistance, making them suitable for use in harsh environments or applications exposed to corrosive substances.

Application Areas:

- Automotive Industry: Engine components, suspension systems, steering mechanisms

- Aerospace: Landing gear, flight control systems, turbine engines

- Heavy Machinery: Excavators, bulldozers, cranes, agricultural equipment

- Marine Applications: Propeller shafts, rudder bearings, deck equipment

- Oil and Gas: Pumps, compressors, drilling equipment

- Power Generation: Turbines, generators, wind energy systems

- Material Handling: Conveyor systems, lift trucks, packaging machinery

- Textile Machinery: Spinning machines, weaving looms, finishing equipment

- Paper and Pulp Industry: Rollers, presses, drying cylinders

- Food Processing: Mixers, grinders, packaging equipment

- Medical Equipment: Imaging machines, surgical tools, rehabilitation devices

- Robotics and Automation: Robotic arms, linear actuators, assembly lines

Quality Control:

We implement rigorous quality control measures throughout our production process.

Factory related:

Provide suitable bearing products and supporting services according to the needs of different customers

Packaging and Transportation:

We ensure secure packaging and reliable shipping for all orders.

Shipping Samples:

Sample orders are available for testing and evaluation.

Qualification Certification:

We hold ISO 9001 certification for quality management.

Production process related:

Select appropriate raw materials to produce bearing products that meet technical requirements

Exhibitions:

We regularly participate in international trade shows to showcase our products.

FAQ:

- What is the minimum order quantity for the Bimetallic Bushing Sleeve?

We offer flexible order quantities to accommodate your needs. Please contact us for details. - Can you provide custom sizes for the products?

Yes, we specialize in customizing our products to meet your specific requirements. - What is the typical lead time for orders?

Lead times vary depending on the order size and specifications. We strive for quick turnaround times and will provide an accurate estimate upon inquiry. - Do you offer technical support for product selection and implementation?

Absolutely! Our team of experts is available to assist you in choosing the right product for your application and provide guidance on implementation.

Contact Us:

For more information about our bimetallic bushing sleeves or to discuss your specific requirements, please reach out to us at info@wingold.cc. Our team is ready to provide you with expert advice and tailored solutions to meet your sliding bearing needs.

Learn about our latest products and discounts through SMS or email