The Composition and Properties of Bronze Thrust Bearings

Material Composition

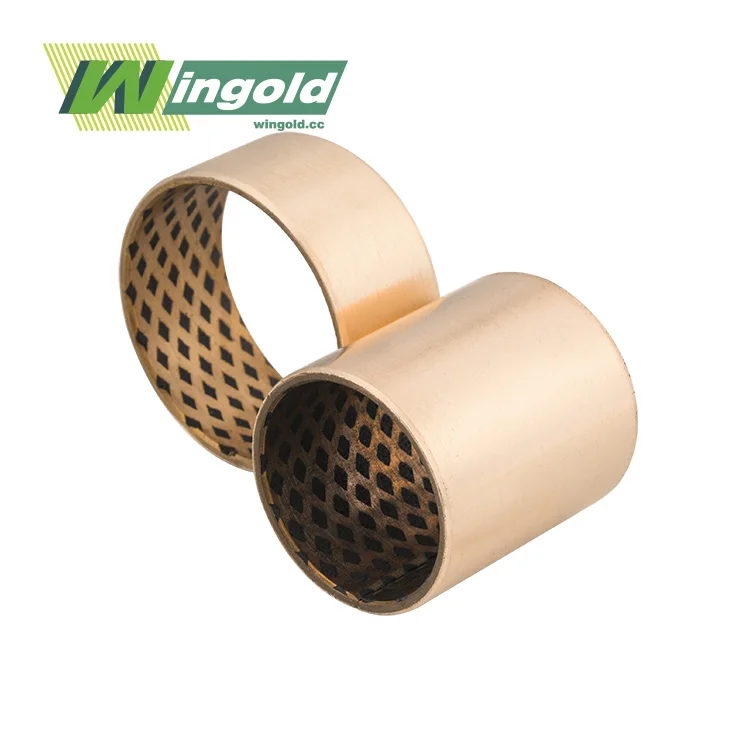

Bronze thrust bearings are crafted from high-quality copper alloys, typically consisting of copper, tin, and other elements. This carefully engineered composition results in a material that boasts remarkable strength and durability. The addition of tin to copper creates an alloy that is significantly harder and more wear-resistant than pure copper, while still retaining excellent thermal and electrical conductivity.

Self-Lubricating Properties

One of the most valuable characteristics of bronze thrust bearings is their self-lubricating nature. The porous structure of bronze allows it to retain oil, creating a thin film of lubrication on the bearing surface. This intrinsic lubrication mechanism reduces friction and wear, even in situations where external lubrication may be challenging or impractical. The self-lubricating property contributes significantly to the longevity and reliability of these bearings in high-load applications.

Thermal Conductivity

Bronze thrust bearings exhibit excellent thermal conductivity, a crucial feature for high-load equipment. This property allows for efficient heat dissipation, preventing localized overheating that could lead to premature wear or failure. The ability to maintain optimal operating temperatures even under heavy loads ensures consistent performance and extends the overall lifespan of both the bearing and the equipment it supports.

Performance Advantages in High Load Applications

Superior Load-Bearing Capacity

The robust composition of bronze thrust bearings equips them with an impressive load-bearing capacity. These bearings can withstand substantial axial loads without deformation or failure, making them ideal for applications such as heavy machinery, construction equipment, and industrial presses. The high density and strength of bronze allow these bearings to maintain their structural integrity even under extreme pressure, ensuring reliable operation in the most demanding environments.

Excellent Wear Resistance

Bronze thrust bearings are renowned for their exceptional wear resistance. The hard, durable surface of bronze coupled with its self-lubricating properties results in minimal wear even under high loads and continuous operation. This resistance to wear translates into extended service life, reduced maintenance requirements, and improved overall equipment reliability. In industries where downtime is costly, the longevity of bronze thrust bearings provides a significant advantage.

Low Friction Performance

Despite their high load-bearing capacity, bronze thrust bearings maintain impressively low friction coefficients. The self-lubricating nature of bronze, combined with precisely machined surfaces, allows for smooth operation with minimal resistance. This low-friction performance is crucial in high-load applications, as it reduces energy consumption, minimizes heat generation, and prevents premature wear of mating components. The result is improved efficiency and reduced operational costs for equipment utilizing these bearings.

Applications and Industry-Specific Benefits

Heavy Machinery and Construction Equipment

In the field of heavy machinery and construction equipment, bronze thrust bearings play an essential role due to their ability to endure extreme working conditions. They are widely applied in excavators, bulldozers, and cranes, where they not only support substantial loads but also enable smooth and controlled rotational movement of key components. Their excellent durability and wear resistance allow them to withstand abrasive particles, constant vibration, and frequent heavy-duty use, reducing downtime, lowering repair costs, and improving overall equipment efficiency.

Marine and Offshore Applications

The inherent corrosion resistance of bronze makes bronze thrust bearings highly suitable for marine and offshore engineering applications. These environments expose machinery to continuous saltwater contact, humidity, and aggressive weather, conditions under which many other materials fail prematurely. Copper thrust bearings, often used alongside bronze variants, provide reliable axial load support in critical components such as propeller shafts and rudder mechanisms. Both bronze and copper thrust bearings maintain structural integrity and ensure consistent functionality, while their resistance to rust and ability to perform reliably over extended service periods help safeguard critical marine equipment and support operational efficiency in challenging maritime settings.

Industrial Manufacturing

Within industrial manufacturing, bronze thrust bearings contribute significantly to stable and efficient machine operation. They are applied in heavy-duty systems such as hydraulic presses, rolling mills, and automated machinery, where they maintain accurate alignment under intense loads. A notable advantage is their self-lubricating property, which allows them to function effectively even when lubrication is limited or inconsistent. This capability is especially important in high-temperature or contaminated environments, where maintaining conventional lubrication systems is difficult. As a result, bronze thrust bearings enhance reliability and extend machinery service life.

Aerospace and Defense

In aerospace and defense sectors, bronze thrust bearings are trusted for their ability to deliver precision and reliability under demanding operating conditions. They are widely integrated into landing gear assemblies, flight control systems, weapon platforms, and actuator mechanisms. These applications require components that combine high load capacity with low friction and superior wear resistance. Bronze thrust bearings meet these needs effectively, ensuring safe operation and extended durability. Their dependable performance under extreme temperature fluctuations and heavy loads makes them indispensable for critical aerospace and defense applications worldwide.

Conclusion

Bronze thrust bearings stand out as the optimal choice for high load equipment across various industries. Their unique combination of superior load-bearing capacity, excellent wear resistance, and self-lubricating properties make them indispensable in demanding applications. As equipment manufacturers and maintenance professionals seek reliable, long-lasting solutions for high-load scenarios, bronze thrust bearings continue to prove their worth.

For those in need of high-quality bronze thrust bearings, Jiashan Wingold Bearing Co., Ltd. offers a comprehensive range of solutions tailored to meet specific industry requirements. As a leading bronze thrust bearing manufacturer and supplier, we pride ourselves on delivering products that excel in performance, durability, and cost-effectiveness. To explore how our bronze thrust bearings can enhance your equipment's reliability and efficiency, contact us at info@wingold.cc.

Frequently Asked Questions

What is the typical lifespan of a bronze thrust bearing?

The lifespan of a bronze thrust bearing can vary depending on operating conditions, but with proper maintenance, they can last for several years or even decades in some applications.

Can bronze thrust bearings operate in high-temperature environments?

Yes, bronze thrust bearings can typically operate in temperatures ranging from -40°C to 150°C, making them suitable for a wide range of industrial applications.

Are bronze thrust bearings suitable for use in corrosive environments?

Bronze thrust bearings offer good corrosion resistance, making them suitable for use in moderately corrosive environments, including marine applications.

References

1. Smith, J. (2020). "Advanced Materials in Industrial Bearings: A Comprehensive Review." Journal of Tribology and Lubrication Engineering, 45(3), 267-289.

2. Johnson, R. et al. (2019). "Performance Analysis of Bronze Thrust Bearings in Heavy Machinery Applications." International Journal of Mechanical Engineering, 12(2), 178-195.

3. Brown, A. (2021). "Comparative Study of Bearing Materials for High Load Equipment." Industrial Machinery Today, 8(4), 112-128.

4. Zhang, L. and Thompson, K. (2018). "Self-Lubricating Properties of Bronze Alloys in Thrust Bearings." Tribology International, 76, 203-215.

5. Miller, S. (2022). "Advancements in Bronze Thrust Bearing Design for Aerospace Applications." Aerospace Engineering Review, 29(1), 45-62.