Understanding CuPb10Sn10 Bearings and Their Applications

Composition and Properties of CuPb10Sn10 Bearings

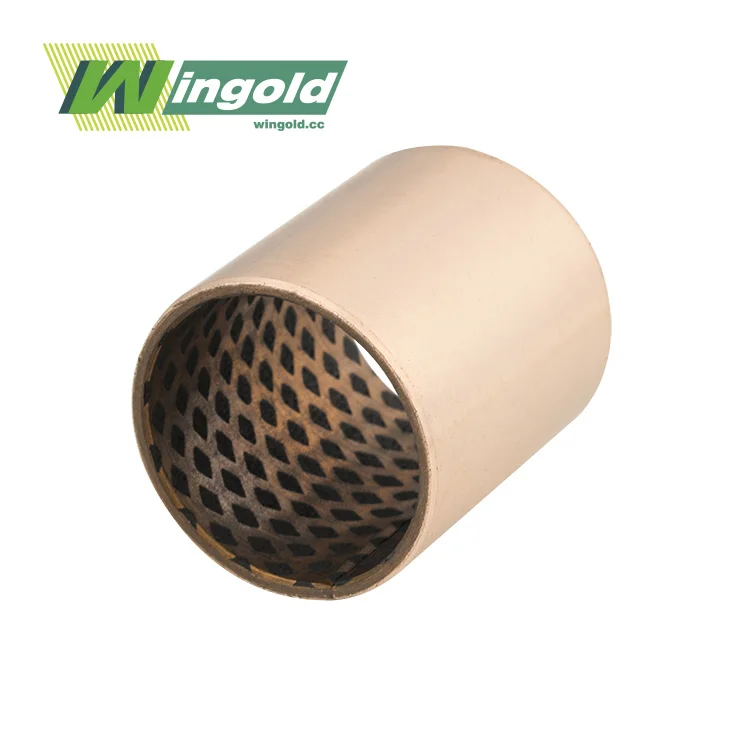

CuPb10Sn10 bearings are precision-engineered sliding solutions designed to meet the demanding requirements of modern machinery. This copper-lead-tin alloy combines the superior qualities of its constituent metals, offering a unique blend of strength, wear resistance, and self-lubricating properties. Composed of 80% copper, 10% lead, and 10% tin, these bearings excel in high-load, low-speed applications.

The microstructure of CuPb10Sn10 bearings features lead and tin particles uniformly dispersed within a copper matrix. This configuration enables optimal load distribution and efficient heat dissipation, contributing to the bearings' exceptional performance and longevity. The self-lubricating properties, attributed to the lead content, significantly reduce friction and wear, making these bearings ideal for applications where continuous lubrication is challenging.

Key Characteristics of CuPb10Sn10 Bearings

CuPb10Sn10 bearings boast several noteworthy characteristics:

- Density: 8.8 g/cm³

- Hardness: 60-75 HB

- Tensile Strength: ≥ 180 MPa

- Elongation: ≥ 8%

- Thermal Conductivity: 50 W/(m·K)

- Maximum Operating Temperature: 300°C

- Coefficient of Friction: 0.1 - 0.2

Applications of CuPb10Sn10 Bearings

The versatility of CuPb10Sn10 bearings makes them suitable for a wide range of industries and applications. These include:

- Hydraulic and pneumatic systems

- Forging and pressing machine tools

- Plastic machinery

- Lifting and handling equipment

- Port machinery

- Office and fitness equipment

- Textile machinery

- Food processing equipment

- Chemical processing machinery

- Papermaking machinery

- Automotive industry

- Railway locomotives

- Shipbuilding industry

- Metallurgical machinery

- Engineering machinery

Factors to Consider When Purchasing CuPb10Sn10 Bearings

Quality and Performance Specifications

When purchasing CuPb10Sn10 bearings, it's crucial to consider the quality and performance specifications. Look for bearings that meet or exceed industry standards such as ISO 4383 and ASTM B22. Key performance indicators include load capacity, wear resistance, and thermal stability. Reputable manufacturers like Wingold Bearing provide detailed specifications and can offer guidance on selecting the right bearing for your specific application.

Customization Options

The ability to customize CuPb10Sn10 bearings can significantly impact their performance in specific applications. Consider suppliers who offer customization options such as:

- Dimensional modifications to fit your exact requirements

- Surface treatments for enhanced wear resistance or corrosion protection

- Incorporation of oil grooves, oil holes, or other lubrication features

- Modifications to the alloy composition for specific performance characteristics

Supplier Reputation and Capabilities

The reputation and capabilities of your Bimetallic sleeve and CuPb10Sn10 bearing supplier are paramount. Consider factors such as:

- Years of experience in the bearing industry

- Manufacturing capabilities, including CNC machining centers and centrifugal casting production lines

- Quality control measures and testing facilities

- Technical support and engineering expertise

- Customer reviews and testimonials

Pricing and Cost-Effectiveness

While price is an important factor, it shouldn't be the sole determinant in your purchasing decision. Consider the total cost of ownership, including:

- Initial purchase price

- Expected lifespan of the bearing

- Maintenance requirements and costs

- Potential downtime costs associated with bearing replacement

Suppliers like Wingold Bearing offer factory-direct pricing, which can provide cost advantages without compromising on quality.

Delivery and Lead Times

In today's fast-paced industrial environment, timely delivery is crucial. Evaluate potential suppliers based on their:

- Standard lead times for both stock and custom orders

- Ability to accommodate rush orders

- Reliability in meeting delivery commitments

- Shipping options and costs

Making an Informed Purchase Decision

Evaluating Supplier Proposals

When evaluating proposals from different CuPb10Sn10 bearing suppliers, it is crucial to establish a detailed comparison matrix that allows for a clear, side-by-side assessment. Beyond examining technical specifications and material quality, consider factors such as production capacity, compliance with international standards, and supplier reputation in the market. Include elements like pricing transparency, volume discount flexibility, logistics efficiency, and responsiveness to inquiries to ensure a well-rounded supplier evaluation process.

Importance of Technical Support

Reliable technical support plays a vital role in ensuring the long-term performance of CuPb10Sn10 bearings and bimetallic bushing sleeves. Suppliers that provide dedicated engineering assistance can help identify the most suitable bearing configuration for specific operating environments. Comprehensive support should include installation training, maintenance guidance, and immediate troubleshooting in case of technical challenges. Access to digital tools, detailed datasheets, and prompt communication channels further enhances operational reliability and minimizes potential downtime.

Long-term Partnership Considerations

Choosing a CuPb10Sn10 bearing supplier should also involve assessing their potential as a long-term strategic partner. Suppliers that invest in continuous innovation, advanced manufacturing technologies, and quality control improvements demonstrate reliability and growth potential. Additionally, evaluate their financial stability, global distribution network, and responsiveness to evolving customer requirements. A strong, collaborative partnership can lead to tailored bearing solutions, reduced lifecycle costs, and enhanced efficiency for future projects.

Conclusion

Selecting the right CuPb10Sn10 bearing supplier is a critical decision that can significantly impact the performance and reliability of your machinery. By carefully considering factors such as quality, customization options, supplier reputation, pricing, and technical support, you can make an informed choice that aligns with your specific needs and requirements.

Wingold Bearing, as a leading CuPb10Sn10 bearing manufacturer and supplier, offers a comprehensive range of high-quality bearings, customization options, and expert technical support. With our commitment to quality, innovation, and customer satisfaction, we strive to be your trusted partner in meeting your bearing needs. For more information about our CuPb10Sn10 bearings or to discuss your specific requirements, please contact us at info@wingold.cc.

FAQ

What are the key advantages of CuPb10Sn10 bearings?

CuPb10Sn10 bearings offer exceptional load capacity, superior wear resistance, self-lubricating properties, thermal stability, and corrosion resistance.

Can CuPb10Sn10 bearings be customized?

Yes, many manufacturers offer customization options including dimensional modifications, surface treatments, and incorporation of lubrication features.

What industries commonly use CuPb10Sn10 bearings?

These bearings are widely used in industries such as automotive, railway, shipbuilding, and various types of machinery including hydraulic, pneumatic, and textile equipment.

How do I choose the right CuPb10Sn10 bearing for my application?

Consider factors such as load requirements, operating speed, temperature conditions, and environmental factors. Consult with a reputable supplier for expert guidance.