Understanding Large Bronze Bushings: Characteristics and Applications

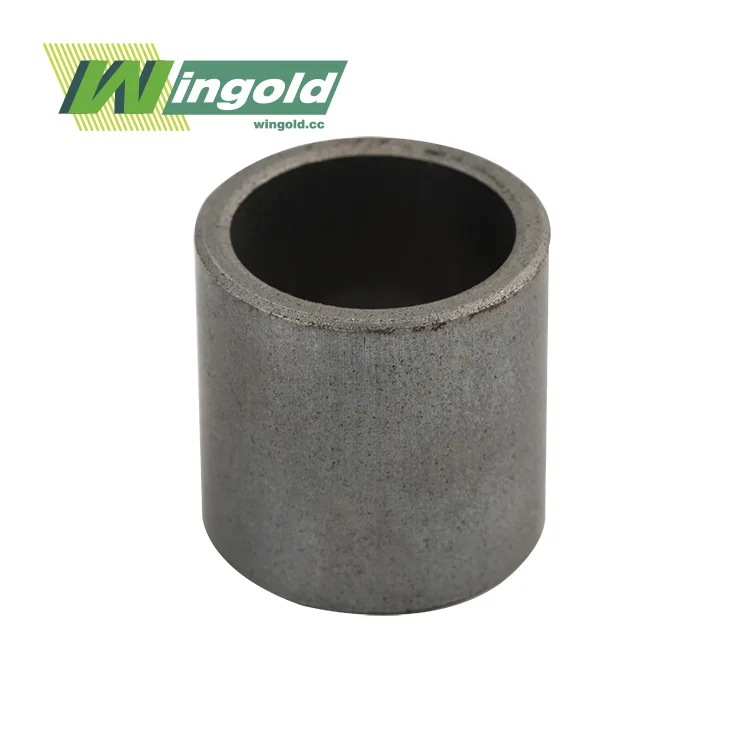

Large bronze bushings, also known as oversized bronze bearings, are specialized components designed to handle substantial loads and dimensions in various industrial applications. These precision-engineered parts are crafted from high-quality bronze alloys, such as C93200 (SAE 660) and C86300, known for their exceptional mechanical properties and corrosion resistance.

Key Features of Large Bronze Bushings

Large bronze bushings boast several advantageous characteristics that make them ideal for demanding industrial environments:

- Superior load-bearing capacity (up to 150 MPa)

- Excellent wear resistance

- High thermal conductivity

- Self-lubricating properties

- Dimensional stability

- Corrosion resistance

These features contribute to reduced maintenance requirements, extended operational life, and consistent performance under heavy loads and extreme conditions.

Common Applications

Large bronze bushings find extensive use across various industries due to their versatility and robust performance. Some common applications include:

- Heavy machinery and equipment

- Marine and offshore installations

- Steel mills and metalworking plants

- Mining and construction equipment

- Power generation facilities

- Paper and pulp processing plants

The ability of large bronze bushings to withstand harsh environments and heavy loads makes them indispensable in these industries.

Mounting Techniques for Large Bronze Bushings

Proper mounting of large bronze bushings is crucial for ensuring optimal performance and longevity. The following techniques are recommended for effective installation:

Press-Fit Method

The press-fit method is a common technique for mounting large bronze bushings, and proper bronze bushing lubrication plays an important role in ensuring successful installation and long-term performance. This approach involves creating an interference fit between the bushing and the housing. Key considerations for this method include:

- Precise machining of both the bushing and housing to achieve the correct interference

- Use of specialized pressing equipment to apply uniform force

- Gradual and controlled application of pressure to prevent damage

- Proper alignment to ensure even distribution of loads

Thermal Expansion Technique

For larger bushings or those requiring a tighter fit, the thermal expansion technique can be employed. This method involves:

- Cooling the bushing to contract its dimensions

- Heating the housing to expand its bore

- Quickly inserting the cooled bushing into the heated housing

- Allowing the components to return to ambient temperature, creating a secure fit

Mounting Considerations

Regardless of the chosen method, several factors should be considered during the mounting process:

- Cleanliness: Ensure all components are free from debris and contaminants

- Lubrication: Apply a thin layer of lubricant to facilitate installation

- Alignment: Use specialized tools to ensure proper alignment during mounting

- Support: Provide adequate support to prevent distortion or damage during installation

- Inspection: Conduct thorough post-installation checks to verify proper fit and alignment

Lubrication Strategies for Large Bronze Bushings

Effective lubrication is essential for maintaining the performance and extending the operational lifespan of large bronze bushings used in heavy-duty machinery and industrial systems. Although bronze bushings naturally exhibit some degree of self-lubrication, additional lubrication techniques are often required to cope with high-load, high-speed, or high-temperature environments. Proper lubrication minimizes friction and wear, prevents metal-to-metal contact, and helps dissipate heat generated during operation. Implementing the right lubrication strategy ensures smoother movement, reduced maintenance frequency, and consistent long-term performance under demanding conditions.

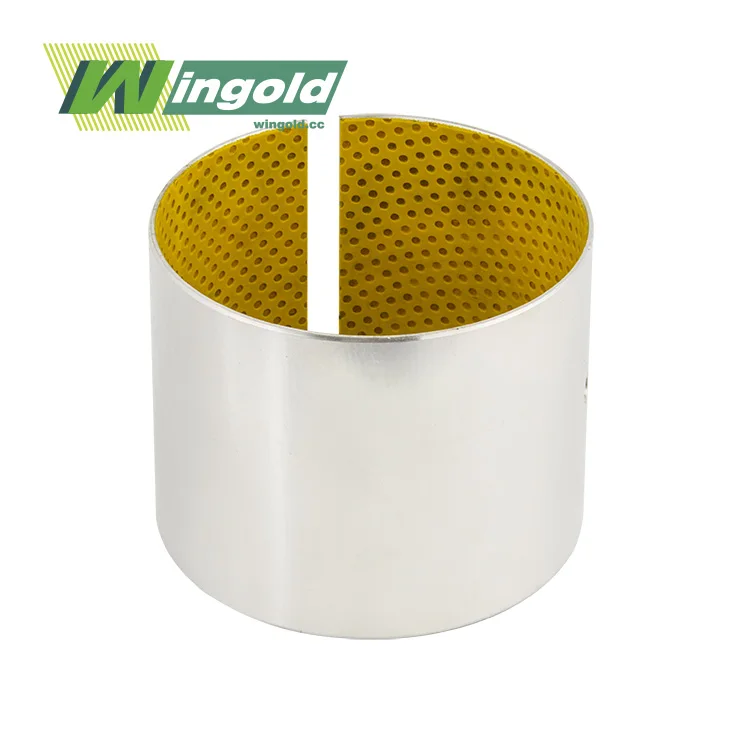

Self-Lubricating Properties

Many large bronze bushings are engineered with built-in self-lubricating capabilities, reducing the need for frequent manual lubrication. These properties can be achieved by impregnating the bushing material with lubricating oils or embedding solid lubricants such as graphite, PTFE, or MoS₂ during the manufacturing process. Additionally, surface coatings or composite bronze alloys can further enhance lubricity, especially under dry or marginal lubrication conditions. Such self-lubricating mechanisms not only improve wear resistance but also significantly lower maintenance costs and minimize operational interruptions, making them ideal for continuous or hard-to-access machinery.

External Lubrication Systems

In applications involving extreme pressure, rapid motion, or high thermal loads, external lubrication systems are often required to supplement the inherent lubricity of bronze bushings. These systems may include grease fittings for manual lubrication at set intervals, automated lubrication units for consistent delivery, or oil circulation systems designed to cool and flush contaminants from the bearing interface. In specialized cases, spray or mist lubrication can be applied to reach rotating or enclosed components. Implementing a well-designed external lubrication system enhances load capacity, ensures temperature stability, and extends the service life of the bushing under demanding operational conditions.

Lubrication Best Practices

Maintaining effective lubrication for large bronze bushings requires a systematic and preventive approach. Begin by selecting high-quality lubricants that are chemically compatible with bronze and formulated for specific temperature and load conditions. Establish a regular lubrication schedule based on operating hours or load cycles to ensure consistent performance. Regularly monitor lubricant condition—checking for contamination, viscosity changes, or oxidation—and avoid both over- and under-lubrication. Clean lubrication points frequently to prevent dirt buildup, and employ condition monitoring technologies such as vibration or temperature sensors to detect lubrication deficiencies early. These best practices help optimize performance and reduce costly downti

Conclusion

Proper mounting and lubrication of large bronze bushings are critical factors in ensuring their optimal performance and longevity in industrial applications. By understanding the unique characteristics of these components and implementing appropriate installation and maintenance techniques, you can maximize their efficiency and service life.

As a leading large bronze bushing supplier and manufacturer, Wingold Bearing offers a wide range of high-quality products designed to meet the most demanding industrial requirements. Our team of experts is ready to assist you in selecting the right bushing for your application and provide guidance on proper mounting and lubrication techniques. For more information about our large bronze bushings or to discuss your specific needs, please contact us at info@wingold.cc. Let Wingold Bearing be your trusted partner in optimizing your industrial operations with our precision-engineered bronze bushing solutions.

FAQs

What is the typical lifespan of a large bronze bushing?

The lifespan of a large bronze bushing can vary significantly depending on factors such as application, loading conditions, and maintenance practices. With proper installation and maintenance, these bushings can last for several years or even decades.

Can large bronze bushings operate in water or other liquids?

Yes, bronze bushings are often used in marine and other liquid-exposed applications due to their excellent corrosion resistance. However, special considerations for lubrication and material selection may be necessary.

How often should large bronze bushings be inspected?

Inspection frequency depends on the application and operating conditions. Generally, a visual inspection should be performed at least annually, with more frequent checks for critical or high-load applications.