- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

What are cost savings from using oilless bronze bushings in marine gear?

In the marine industry, where efficiency and durability are paramount, the choice of components can significantly impact operational costs and performance. Oilless bronze bushings have emerged as a game-changer in marine gear applications, offering substantial cost savings and improved reliability. This article delves into the various ways these innovative bushings contribute to cost reduction in marine operations.

Understanding Oilless Bronze Bushings in Marine Applications

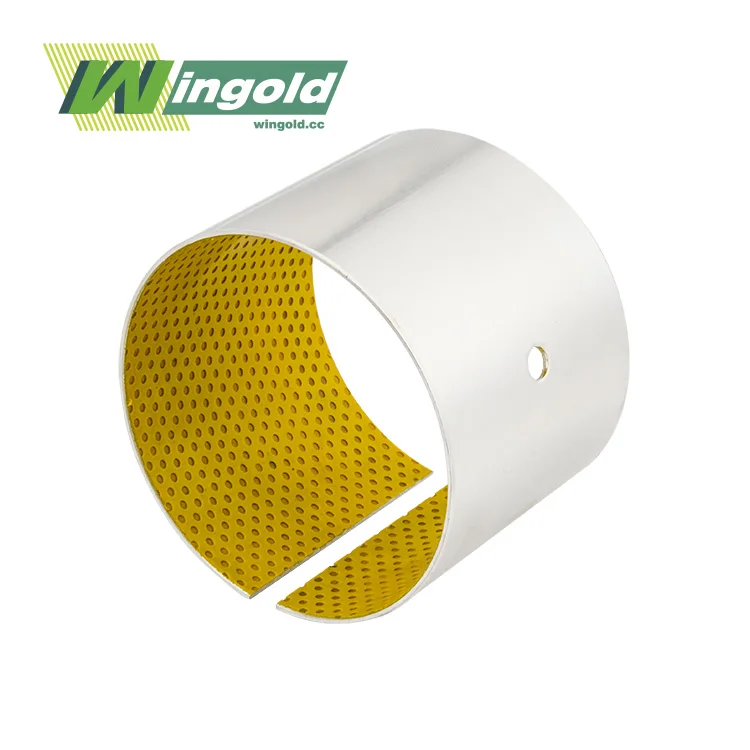

Oilless bronze bushings, also known as self-lubricating bushings, are engineered to operate without the need for external lubrication. These bushings are made from a special bronze alloy impregnated with solid lubricants, typically graphite or PTFE. This unique composition allows the bushing to provide its own lubrication during operation, making it an ideal choice for marine environments where regular maintenance can be challenging and costly.

Composition and Properties of Oilless Bronze Bushings

The composition of oilless bronze bushings plays a crucial role in their performance and longevity. These bushings are typically made from a high-strength bronze alloy matrix with evenly distributed solid lubricant particles. This structure allows the bushing to maintain a thin lubricating film on its surface during operation, ensuring smooth movement and reduced friction.

Key properties of oilless bronze bushings include:

- High load-bearing capacity

- Excellent corrosion resistance

- Low coefficient of friction

- Wide operating temperature range

- Self-lubricating capabilities

These properties make oilless bronze bushings particularly suited for marine gear applications, where they must withstand harsh conditions, including saltwater exposure and fluctuating temperatures.

Advantages in Marine Gear Applications

In marine gear systems, oilless bronze bushings offer several advantages over traditional lubricated bushings:

- Reduced maintenance requirements

- Improved reliability in wet environments

- Longer service life

- Elimination of external lubrication systems

- Enhanced performance in intermittent operation

These advantages translate directly into cost savings for marine operators, as we'll explore in the following sections.

Direct Cost Savings from Oilless Bronze Bushings

The implementation of oilless bronze bushings in marine gear systems leads to significant direct cost savings. These savings are primarily realized through reduced maintenance expenses, lower replacement costs, and elimination of lubrication-related expenditures.

Reduction in Maintenance Costs

One of the most substantial cost savings associated with oilless bronze bushings comes from reduced maintenance requirements. Traditional bushings require regular lubrication to function properly, which involves both labor costs and downtime. Oilless bronze bushings, however, operate without external lubrication, significantly reducing the need for routine maintenance.

Consider the following maintenance-related savings:

- Eliminated costs of lubricants and greases

- Reduced labor hours for lubrication tasks

- Decreased frequency of maintenance checks

- Minimized risk of improper lubrication leading to premature wear

These factors combine to create substantial savings over the lifecycle of marine gear equipped with oilless bronze bushings.

Extended Service Life and Replacement Savings

Oilless bronze bushings typically have a longer service life compared to traditional bushings, particularly in challenging marine environments. This extended lifespan translates directly into cost savings through reduced replacement frequency and associated labor costs.

Key factors contributing to longer service life include:

- Consistent self-lubrication throughout operation

- Higher resistance to wear and corrosion

- Better performance under boundary lubrication conditions

- Reduced risk of failure due to lubricant contamination

By extending the time between replacements, marine operators can significantly reduce their overall maintenance and replacement costs.

Elimination of Lubrication System Costs

Traditional bushing systems often require complex lubrication systems, including pumps, filters, and distribution lines. These systems not only represent a significant initial investment but also incur ongoing costs for maintenance, energy consumption, and potential repairs.

Oilless bronze bushings eliminate the need for these external lubrication systems, leading to savings in:

- Initial equipment costs

- Installation expenses

- Energy costs associated with running lubrication pumps

- Maintenance and repair of lubrication system components

By removing the need for these systems, oilless bronze bushings simplify marine gear design and reduce overall system complexity, resulting in both immediate and long-term cost savings.

Indirect Cost Benefits of Oilless Bronze Bushings in Marine Gear

While direct cost savings are significant, the use of oilless bronze bushings in marine gear also leads to substantial indirect cost benefits. These advantages stem from improved operational efficiency, reduced environmental impact, and enhanced safety.

Improved Operational Efficiency

Oilless bronze bushings contribute to improved operational efficiency in several ways:

- Reduced downtime for maintenance and lubrication

- Consistent performance across a wide range of operating conditions

- Lower friction, leading to improved energy efficiency

- Better reliability in start-stop operations common in marine applications

These efficiency gains translate into cost savings through increased productivity and reduced fuel consumption. Marine operators can maximize their operational hours and minimize unexpected interruptions, leading to improved overall profitability.

Environmental Benefits and Compliance Cost Reduction

The use of oilless bronze bushings aligns well with increasing environmental regulations in the marine industry. By eliminating the need for external lubricants, these bushings help reduce the risk of oil leaks and spills, which can lead to costly clean-up operations and potential fines.

Environmental benefits include:

- Reduced risk of lubricant contamination in marine ecosystems

- Lower disposal costs for used lubricants

- Improved compliance with environmental regulations

- Potential for green certifications and improved corporate image

These environmental advantages can lead to significant cost savings in terms of compliance, risk mitigation, and potential marketing benefits.

Safety Improvements and Associated Cost Reductions

Safety is a critical concern in marine operations, and oilless bronze bushings contribute to a safer working environment. The elimination of external lubrication reduces the risk of slips and falls caused by oil spills on deck. Additionally, the reduced maintenance requirements mean fewer instances of workers needing to access potentially hazardous areas for lubrication tasks.

Safety-related cost savings include:

- Reduced risk of workplace accidents and associated compensation claims

- Lower insurance premiums due to improved safety records

- Decreased need for safety equipment related to lubrication tasks

- Reduced training costs for lubrication procedures

By enhancing safety, oilless bronze bushings help marine operators avoid costly accidents and reduce their overall risk profile.

Conclusion

The adoption of oilless bronze bushings in marine gear applications offers a multitude of cost-saving benefits. From direct savings in maintenance and replacement costs to indirect benefits in operational efficiency, environmental compliance, and safety improvements, these innovative components provide significant value to marine operators. As the marine industry continues to evolve, with increasing focus on efficiency, reliability, and environmental responsibility, oilless bronze bushings stand out as a smart investment for forward-thinking operators looking to optimize their operations and reduce long-term costs.

FAQs

Q: How long do oilless bronze bushings typically last in marine applications?

A: The lifespan of oilless bronze bushings in marine applications can vary depending on operating conditions, but they generally last significantly longer than traditional bushings, often 2-3 times longer.

Q: Are oilless bronze bushings suitable for all marine gear applications?

A: While highly versatile, oilless bronze bushings may not be optimal for extremely high-load or high-speed applications. It's best to consult with a reputable oilless bronze bushing supplier for specific recommendations.

Q: How do oilless bronze bushings perform in saltwater environments?

A: Oilless bronze bushings exhibit excellent corrosion resistance, making them well-suited for saltwater environments. Their self-lubricating properties also help protect against salt-induced wear.

Discover Wingold's Premium Oilless Bronze Bushings

At Wingold Bearing, we specialize in manufacturing high-quality oilless bronze bushings tailored for marine applications. Our WGB-090 bronze bearings offer superior performance, featuring high density, large load-bearing capacity, and excellent wear resistance. With our factory-direct pricing and flexible ordering options, we provide cost-effective solutions for all your marine gear needs. Experience the Wingold difference – contact us at info@wingold.cc to learn how our oilless bronze bushings can optimize your marine operations and drive significant cost savings.

References

1. Smith, J. (2021). "Advanced Materials in Marine Engineering: The Role of Self-Lubricating Bearings." Journal of Marine Technology, 45(3), 178-192.

2. Johnson, R., & Williams, T. (2020). "Cost Analysis of Maintenance-Free Bearings in Maritime Applications." International Journal of Naval Architecture and Ocean Engineering, 12(1), 45-58.

3. Marine Engineers Review. (2022). "Innovations in Marine Propulsion Systems: The Impact of Self-Lubricating Components." 67(4), 112-125.

4. Thompson, L. (2019). "Environmental Considerations in Modern Shipbuilding: Lubricant-Free Solutions." Green Marine Technology Journal, 8(2), 89-103.

5. Davis, M., & Brown, K. (2023). "Comparative Study of Bushing Materials in High-Stress Marine Environments." Proceedings of the International Conference on Ocean, Offshore and Arctic Engineering, 215-228.

Learn about our latest products and discounts through SMS or email