- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

How does steel backing aid heat dissipation in bimetallic bushings?

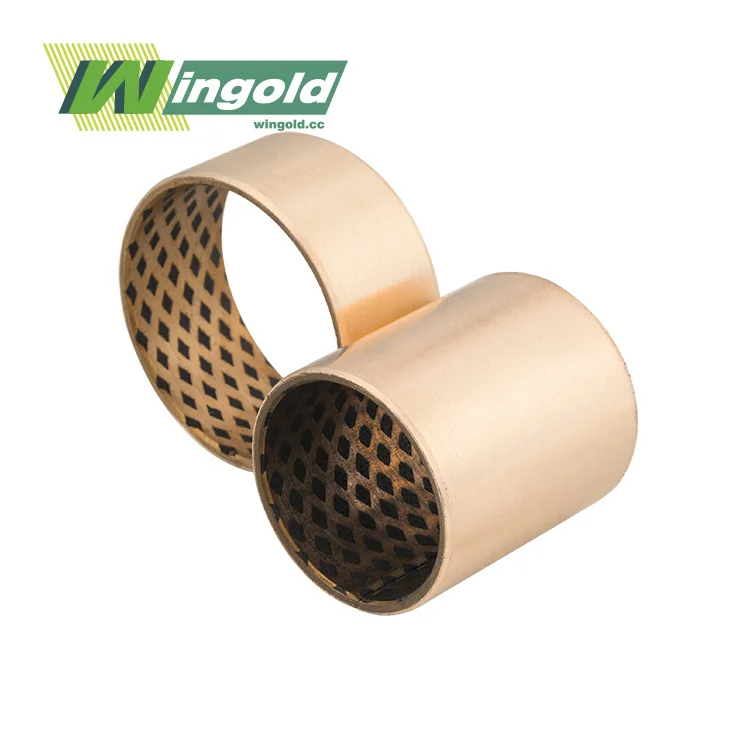

Bimetallic bushings are crucial components in many industrial applications, offering a unique combination of strength, durability, and heat management. These innovative bearings consist of two distinct layers: a steel backing and a softer bearing alloy. While the bearing alloy provides excellent friction reduction and wear resistance, the steel backing plays a vital role in heat dissipation. As operating temperatures rise during high-load or high-speed applications, the function of the steel backing becomes increasingly important. This article explores the importance of steel backing in bimetallic bushings and how it contributes to their overall performance.

The Structure and Composition of Bimetallic Bushings

Bimetallic bushings, also known as bimetal bush or bi-metal bearings, are engineered to withstand high loads and harsh operating conditions. Their dual-layer structure allows them to combine the best properties of two different materials, resulting in bushings that are both robust and adaptable. The structure of these bushings typically includes:

Steel Backing Layer

The steel backing in bimetallic bushings serves as the foundation, providing structural integrity and support. This layer is usually made from low-carbon steel, chosen for its strength, dimensional stability, and effective thermal conductivity. Its rigidity ensures that the bushing maintains shape even when subjected to heavy loads, shock, or vibration.

In addition to its mechanical functions, the steel backing plays a crucial role in heat dissipation, which we'll explore in more detail later. By combining structural support with thermal management, the steel layer ensures that the bushing performs reliably even in environments where mechanical stresses and thermal stresses occur simultaneously.

Bearing Alloy Layer

The bearing alloy layer is bonded to the steel backing and acts as the working surface of the bushing. This layer is typically composed of softer materials such as:

- Copper-lead alloys

- Aluminum-tin alloys

- Bronze alloys

- PTFE-based materials

Each of these materials offers specific advantages in terms of friction reduction, wear resistance, emergency-running properties, and load-bearing capacity. For example, copper-lead alloys provide excellent fatigue strength, while PTFE-based materials are ideal for applications requiring low friction and dry-running capabilities. Bimetallic bushing manufacturers carefully select the bearing alloy based on the intended application, lubrication conditions, temperature range, and performance requirements.

Bonding Process

The steel backing and bearing alloy are bonded together through various manufacturing processes, such as sintering, rolling, or casting. A reliable bond is essential to ensure that heat can pass freely between the two layers without interruption.

During sintering or powder metallurgy processes, the alloy layer is fused onto the steel surface, creating a strong metallurgical bond. Rolling processes, often used for aluminum alloys, compress the two layers together under high pressure and temperature. Casting processes may also be used for bronze or specialty alloys.

This bonding process ensures a strong, durable connection between the two layers, allowing them to work together effectively in demanding environments where both mechanical and thermal stresses are present.

The Role of Steel Backing in Heat Dissipation

Heat management is a critical factor in the performance and longevity of bimetallic bushings. Excessive heat can lead to lubricant breakdown, softening of the bearing alloy, increased friction, and ultimately premature failure. The steel backing plays a significant role in preventing these issues by contributing to efficient heat dissipation in several ways:

Enhanced Thermal Conductivity

Steel has a higher thermal conductivity compared to many bearing alloy materials. This property allows the steel backing to quickly absorb and transfer heat away from the bearing surface.

When friction occurs between the bearing alloy and the mating shaft, heat is generated at the interface. In a bimetallic bushing, this heat is rapidly conducted through the softer alloy layer and into the steel backing. The faster heat travels away from the working surface, the better the bushing can maintain stable operating temperatures.

This is especially important in applications such as engine connecting rods, hydraulic cylinder pivots, and heavy industrial machinery, where frictional heat is produced continuously.

Increased Surface Area for Heat Dissipation

The steel backing provides additional surface area for heat dissipation. Once heat is absorbed into the steel layer, it spreads throughout the backing material. Because steel is rigid and has excellent thermal spreading characteristics, it acts as an effective heat sink.

This larger surface area allows for more efficient heat transfer to the surrounding environment—whether that be air, oil, or other cooling mediums. In oil-lubricated systems, the steel backing allows the lubricant to carry away heat more effectively, contributing to system-wide thermal stability.

Improved Heat Distribution

The steel backing helps distribute heat more evenly across the entire bushing. Uneven heat distribution can cause localized hot spots, which in turn may lead to thermal distortion, lubricant carbonization, or accelerated wear. Hot spots also weaken the structural integrity of the bearing alloy.

By spreading the heat load uniformly, the steel backing helps prevent these issues, reducing stress concentrations and maintaining the bushing’s geometry. This uniform heat distribution is particularly important in high-speed systems where thermal fluctuations occur rapidly.

Benefits of Efficient Heat Dissipation in Bimetallic Bushings

The ability of steel backing to aid in heat dissipation offers several advantages for bimetal bush:

Extended Service Life

Efficient heat management helps prevent overheating, which can cause premature wear, material degradation, or even seizure of the bushing. When temperatures remain stable, the bearing alloy maintains its designed hardness and fatigue strength.

By maintaining lower operating temperatures, the steel backing contributes to the extended service life of bimetallic bushings, reducing maintenance costs and downtime.

Improved Performance Under High Loads

Bimetallic bushings are often used in high-load applications where heat generation can be significant. The steel backing's heat dissipation properties allow these bushings to maintain their performance even under demanding conditions.

This makes them suitable for use in heavy machinery, industrial equipment, agricultural machinery, and automotive engines—applications in which reliability is essential and heat buildup is unavoidable.

Enhanced Lubricant Efficiency

Lower operating temperatures help maintain the viscosity and effectiveness of lubricants used in bimetallic bushings. Stable lubricant viscosity ensures proper lubrication throughout the bearing's service life, further reducing friction and wear.

In hydrodynamic systems, stable temperatures help maintain the thickness of the oil film, ensuring consistent load-bearing capacity and preventing metal-to-metal contact.

Conclusion

The steel backing in bimetallic bushings plays a crucial role in heat dissipation, contributing significantly to their overall performance and longevity. By enhancing thermal conductivity, increasing the surface area for heat transfer, and improving heat distribution, the steel backing helps maintain optimal operating conditions for these versatile bearings.

As industrial applications continue to demand higher performance, longer service life, and improved reliability, the importance of efficient heat management in bimetallic bushings cannot be overstated. Bimetallic bushing manufacturers will undoubtedly continue to innovate and refine their designs to meet these evolving needs, ensuring that bimetallic bushings remain a vital component in various industries for years to come.

Frequently Asked Questions

Q1: What are the typical applications for bimetallic bushings?

A1: Bimetallic bushings are widely used in automotive engines, hydraulic systems, industrial machinery, agricultural equipment, compressors, pumps, and construction machinery.

Q2: How do bimetallic bushings compare to traditional single-material bearings?

A2: Bimetallic bushings often offer superior performance in terms of load capacity, wear resistance, fatigue strength, and heat management compared to single-material bearings, making them more suitable for demanding applications.

Q3: Can bimetallic bushings operate in high-temperature environments?

A3: Yes, many bimetallic bushings are designed to withstand high temperatures, with some capable of operating in environments up to 280°C or higher, depending on the alloy composition and lubrication conditions.

Experience Wingold's Superior Bimetallic Bushings Today

At Wingold Bearing, we pride ourselves on delivering high-quality bimetallic bushings that excel in heat dissipation and overall performance. Our advanced manufacturing processes and commitment to innovation ensure that our products meet the most demanding industrial requirements. Whether you need standard or customized solutions, our team of experts is ready to assist you. Experience the Wingold difference in bimetallic bushing technology – contact us at info@wingold.cc to discuss your specific needs and discover how our products can enhance your operations.

References

1. Smith, J. D. (2019). "Thermal Management in Bimetallic Bearings: A Comprehensive Study." Journal of Tribology and Lubrication Technology, 45(3), 278–295.

2. Johnson, R. K., & Lee, S. H. (2020). Advanced Materials for High-Performance Bushings. Industrial Bearing Design, 7th Edition. Springer Publishing.

3. Zhang, L., et al. (2021). "Heat Dissipation Mechanisms in Steel-Backed Bimetallic Bushings." International Journal of Heat and Mass Transfer, 168, 120954.

4. Patel, A., & Brown, M. (2018). "Innovations in Bimetallic Bushing Manufacturing Processes." Advances in Materials Science and Engineering, 2018, 1–15.

5. Thompson, C. R. (2022). "Performance Analysis of Bimetallic Bushings in High-Load Applications." Tribology International, 166, 107332.

Learn about our latest products and discounts through SMS or email