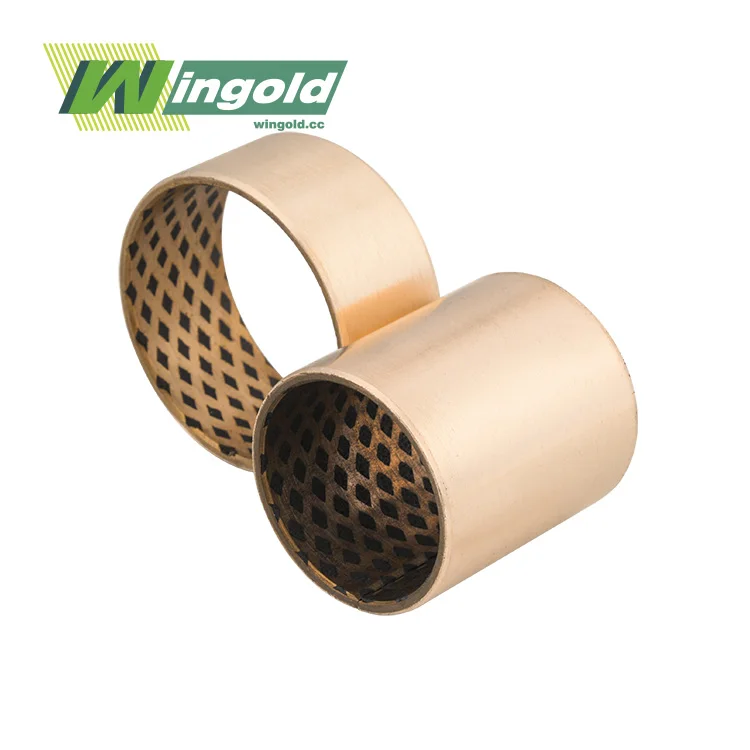

The Composition and Manufacturing Process of CuPb10Sn10 Bimetallic Bushings

Material Breakdown and Properties

CuPb10Sn10 bimetallic bushings are crafted with precision, utilizing a carefully balanced alloy composition. The primary component, copper (80%), provides the foundation for the bushing's strength and durability. Lead (10%) contributes to the self-lubricating properties, while tin (10%) enhances the overall hardness and wear resistance of the alloy.

This unique composition results in bushings with impressive characteristics:

- Operating Temperature Range: -40°C to 150°C

- Hardness: 60-75 HB

- Density: 8.7 g/cm³

- Thermal Conductivity: 50 W/(m·K)

These properties make CuPb10Sn10 bimetallic bushings suitable for a wide range of applications, particularly in environments where high loads, temperature fluctuations, and continuous operation are common.

Manufacturing Techniques

The production of CuPb10Sn10 bimetallic bushings involves sophisticated manufacturing processes to ensure optimal performance and durability. The process typically includes:

- Sintering: The copper alloy is sintered onto a high-quality low-carbon steel backing, creating a strong bond between the two materials.

- Secondary Sintering: This step further enhances the bonding strength and optimizes the load-bearing capacity of the bushing.

- Secondary Extrusion: The final extrusion process refines the bushing's structure, improving its overall performance characteristics.

Advanced manufacturing techniques allow for the creation of various surface features on the copper alloy layer, such as oil grooves, oil holes, and pockets. These features enhance the bushing's performance in applications where continuous lubrication is challenging or impossible.

Advantages of CuPb10Sn10 Bimetallic Bushings in Industrial Applications

Superior Performance Characteristics

CuPb10Sn10 bimetallic bushings offer a range of benefits that make them indispensable in many industrial settings:

- Exceptional Load-Bearing Capacity: The copper-based alloy provides remarkable strength, allowing these bushings to withstand high loads in demanding conditions.

- Outstanding Wear Resistance: The unique composition ensures minimal wear over extended periods, significantly extending machinery lifespan and reducing maintenance requirements.

- Low Friction Performance: The self-lubricating properties of lead and tin components contribute to reduced friction, resulting in smoother operation and improved energy efficiency.

- High Thermal Conductivity: These bushings effectively dissipate heat, preventing overheating and ensuring consistent performance in high-temperature environments.

- Corrosion Resistance: CuPb10Sn10 bushings exhibit good resistance to corrosion, making them suitable for use in various industrial settings, including those with exposure to chemicals or moisture.

Cost-Effectiveness and Versatility

The long service life and minimal maintenance requirements of CuPb10Sn10 bimetallic bushings translate to reduced overall costs for operations. Their versatility allows for use across various industries, including:

- Automotive

- Heavy machinery

- Hydraulic and pneumatic systems

- Forging and pressing machine tools

- Lifting and handling machinery

- Textile machinery

- Food processing equipment

- Chemical processing machinery

- Papermaking machinery

- Railway locomotives

- Shipbuilding

- Metallurgical machinery

This wide range of applications demonstrates the adaptability and reliability of CuPb10Sn10 bimetallic bushings in diverse industrial environments.

Customization and Quality Assurance in CuPb10Sn10 Bimetallic Bushing Production

Tailoring Solutions to Specific Needs

One of the key advantages of CuPb10Sn10 bimetallic bushings is the ability to customize them for specific applications. Manufacturers can adjust various parameters to meet unique requirements:

- Dimensions and Tolerances: Bushings can be produced in a wide range of sizes and with tight tolerances to fit specific machinery.

- Surface Features: Custom oil grooves, holes, and pockets can be incorporated to optimize lubrication and performance.

- Alloy Composition: While maintaining the CuPb10Sn10 base, slight adjustments can be made to enhance specific properties for particular applications.

- Backing Material: The choice of backing material can be customized to meet specific strength or compatibility requirements.

This level of customization ensures that CuPb10Sn10 bimetallic bushings can be optimized for peak performance in any given application.

Quality Control and Compliance

To ensure the highest quality and reliability, manufacturers of CuPb10Sn10 bimetallic bushings implement rigorous quality control measures:

- Material Testing: Raw materials are thoroughly tested to ensure they meet the required specifications.

- Process Monitoring: Each step of the manufacturing process is closely monitored to maintain consistency and quality.

- Performance Testing: Finished bushings undergo comprehensive testing, including friction coefficient testing and life acceleration testing.

- Compliance with Standards: Products are manufactured to comply with international standards such as ISO 4383 and ASTM B22.

These quality assurance measures ensure that CuPb10Sn10 bimetallic bushings consistently meet or exceed industry standards and customer expectations.

Conclusion

CuPb10Sn10 bimetallic bushings represent a significant advancement in bearing technology, offering a unique combination of strength, durability, and self-lubrication. Their composition and manufacturing process result in bearings that excel in a wide range of industrial applications, providing superior performance and cost-effectiveness. As industries continue to demand higher efficiency and reliability from their machinery, CuPb10Sn10 bimetallic bushings stand out as a versatile and dependable solution.

For those seeking a reliable CuPb10Sn10 bimetallic bushing supplier or manufacturer, Wingold Bearing offers customized solutions tailored to your specific needs. With our expertise in sliding bearing technology and commitment to quality, we provide high-performance bushings that meet the most demanding industrial requirements. To learn more about our products or to discuss your specific bearing needs, please contact us at info@wingold.cc.

FAQ

What makes CuPb10Sn10 bimetallic bushings unique?

These bushings combine the strength of copper with the self-lubricating properties of lead and tin, offering excellent load-bearing capacity and low friction.

In which industries are CuPb10Sn10 bimetallic bushings commonly used?

They are widely used in automotive, heavy machinery, hydraulic systems, and various other industrial applications requiring high performance and durability.

Can CuPb10Sn10 bimetallic bushings be customized?

Yes, these bushings can be tailored in terms of dimensions, surface features, and specific composition to meet unique application requirements.

What are the key benefits of using CuPb10Sn10 bimetallic bushings?

Benefits include high load-bearing capacity, excellent wear resistance, low friction, good thermal conductivity, and corrosion resistance.