Advanced Manufacturing Techniques for Bronze Machine Bushings

The production of bronze machine bushings has evolved significantly with the advent of cutting-edge manufacturing technologies. These advancements have revolutionized the way bushings are designed, produced, and customized to meet specific industrial needs.

CNC Machining for Precision and Versatility

Computer Numerical Control (CNC) machining has become a cornerstone in the custom manufacturing of bronze machine bushings. This technology allows for unprecedented precision in creating complex geometries and tight tolerances. CNC machines can produce bushings with intricate oil grooves, precisely sized bores, and custom external features that would be challenging or impossible with traditional manufacturing methods.

The versatility of CNC machining enables manufacturers to produce bronze bushings in a wide range of sizes and shapes, from small, delicate components to large, heavy-duty bushings for industrial machinery. This flexibility is particularly valuable when creating prototypes or small production runs, as it allows for rapid iteration and refinement of designs without the need for expensive tooling changes.

Centrifugal Casting for Enhanced Material Properties

Centrifugal casting is another advanced technique used in the production of high-quality bronze machine bushings. This process involves pouring molten bronze into a rapidly spinning mold, utilizing centrifugal force to distribute the material evenly and create a dense, uniform structure.

The benefits of centrifugal casting for bronze bushings are numerous:

Improved material density and reduced porosity

Enhanced mechanical properties, including strength and wear resistance

Excellent surface finish, reducing the need for post-casting machining

Ability to produce bushings with complex internal features

These attributes make centrifugally cast bronze bushings ideal for applications requiring high load-bearing capacity and extended service life.

Additive Manufacturing for Complex Designs

While still emerging in the field of bronze bushing production, additive manufacturing, or 3D printing, is opening new possibilities for custom designs. This technology allows for the creation of bushings with internal structures and geometries that would be impossible to achieve through traditional manufacturing methods.

3D printing of bronze bushings can offer advantages such as:

Optimized material distribution for weight reduction

Integration of cooling channels or lubrication pathways

Rapid prototyping for design validation

Cost-effective production of small batches or one-off custom parts

As this technology continues to advance, it's likely to play an increasingly important role in the custom manufacturing of bronze machine bushings, particularly for specialized applications requiring unique features or material properties.

Customization Options for Enhanced Performance

The ability to customize bronze machine bushings extends far beyond basic dimensions. Manufacturers can tailor various aspects of bushing design and composition to optimize performance for specific applications.

Alloy Selection and Composition

Bronze is an alloy of copper and tin, but the exact composition can be adjusted to enhance specific properties. Custom bronze alloys for machine bushings might include additives such as:

Lead: Improves machinability and self-lubrication properties

Nickel: Increases strength and corrosion resistance

Aluminum: Enhances hardness and wear resistance

Silicon: Improves fluidity during casting and increases strength

By fine-tuning the alloy composition, manufacturers can create bronze bushings that excel in specific environments or under particular operating conditions.

Surface Treatments and Coatings

Custom surface treatments can significantly enhance the performance of bronze machine bushings. Some options include:

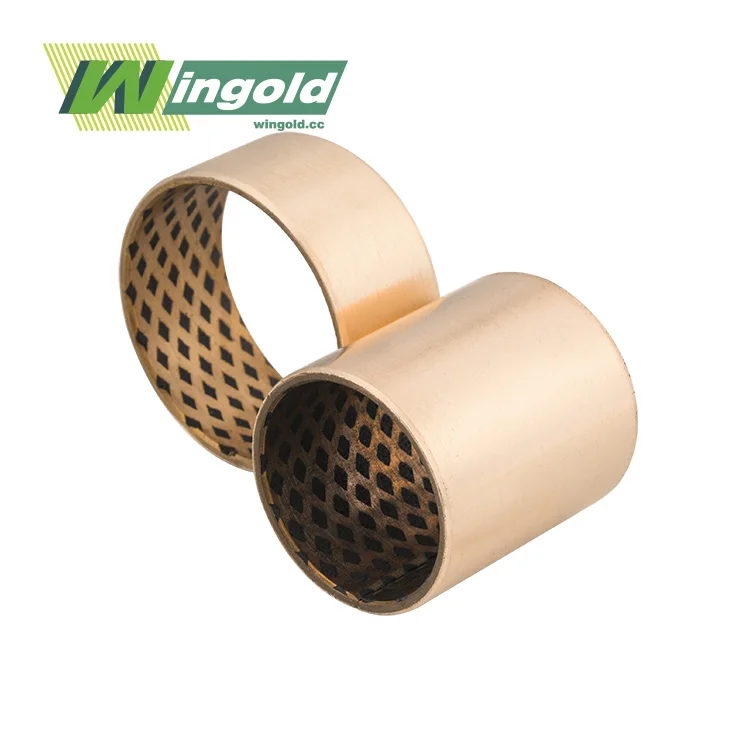

Diamond or hemispherical oil holes: Improve lubrication retention and distribution

Oil grooves: Enhance lubricant flow and coverage

Nitriding: Increases surface hardness and wear resistance

PTFE coating: Reduces friction and improves dry-running capabilities

Shot peening: Enhances fatigue strength and stress corrosion resistance

These surface modifications can be tailored to the specific requirements of the application, optimizing the bushing's performance and longevity.

Geometric Customization

The geometry of bronze machine bushings can be customized to address unique installation or performance requirements. This may include:

Flanged designs for easier mounting or increased load-bearing surface

Split bushings for simplified installation in confined spaces

Tapered bores for precise fit and alignment

Custom external profiles to match housing geometries

Integrated thrust washers or other features to simplify assembly

By tailoring the bushing's geometry, manufacturers can create solutions that not only perform better but also simplify installation and maintenance procedures.

Quality Control and Testing for Custom Bronze Bushings

Ensuring the quality and performance of custom-manufactured bronze machine bushings is crucial for maintaining reliability and customer satisfaction. Rigorous quality control measures and comprehensive testing procedures are essential components of the custom manufacturing process.

Material Verification and Analysis

Before production begins, the bronze alloy composition must be verified to ensure it meets the specified requirements. This typically involves:

Spectrographic analysis to confirm elemental composition

Hardness testing to verify material properties

Microstructure examination to assess grain structure and uniformity

These tests help ensure that the base material will perform as expected and provide the desired characteristics in the finished bushing.

Dimensional Inspection

Precise dimensional control is critical for custom bronze machine bushings. Quality control measures may include:

Coordinate Measuring Machine (CMM) inspection for complex geometries

Laser scanning for rapid, high-precision measurement

Optical comparators for profile and surface finish inspection

Go/No-Go gauging for quick verification of critical dimensions

These inspection techniques ensure that custom bushings meet the exact specifications required for optimal performance in their intended application.

Performance Testing

To validate the performance of custom bronze machine bushings, manufacturers may conduct a range of tests, including:

Friction coefficient testing to assess lubrication properties

Load capacity testing to verify strength and durability

Wear resistance testing to predict service life

Corrosion resistance testing for bushings used in harsh environments

Thermal conductivity testing for applications involving high temperatures

These tests provide valuable data on the bushing's performance under simulated operating conditions, helping to ensure that the custom design meets or exceeds the required specifications.

Life Cycle Acceleration Testing

For critical applications, life cycle acceleration testing can provide insights into the long-term performance and durability of custom bronze bushings. These tests simulate extended use under accelerated conditions, allowing manufacturers to:

Identify potential failure modes

Estimate expected service life

Validate design improvements

Provide customers with reliable performance data

By subjecting custom bushings to rigorous testing, manufacturers can ensure that their products will deliver consistent, reliable performance throughout their intended service life.

Conclusion

Custom manufacturing options for bronze machine bushings offer a wealth of possibilities for optimizing performance, extending service life, and solving unique engineering challenges. By leveraging advanced manufacturing techniques, tailored material compositions, and rigorous quality control processes, manufacturers can create bushings that precisely meet the needs of even the most demanding applications.

As a leading bronze machine bushing supplier and manufacturer, Wingold Bearing is committed to providing innovative, high-quality solutions for your custom bushing needs. Our expertise in sliding bearing solutions, combined with state-of-the-art manufacturing capabilities, ensures that we can deliver bushings that exceed your expectations in terms of performance, durability, and reliability. To learn more about our custom manufacturing options for bronze machine bushings or to discuss your specific requirements, please contact us at info@wingold.cc

.

FAQ

What are the advantages of custom-manufactured bronze machine bushings?

Custom bronze bushings offer optimized performance, enhanced durability, and improved efficiency tailored to specific applications. They allow for precise specifications in size, shape, alloy composition, and surface treatments.

How do CNC machining and centrifugal casting improve bronze bushing quality?

CNC machining provides high precision and versatility, while centrifugal casting enhances material density, strength, and wear resistance. These techniques result in superior quality bushings with improved performance characteristics.

Can bronze bushings be customized for specific operating environments?

Yes, bronze bushings can be customized through alloy selection, surface treatments, and geometric modifications to suit specific operating conditions, including high loads, corrosive environments, or high-temperature applications.

What quality control measures are used in custom bronze bushing manufacturing?

Quality control includes material verification, dimensional inspection, performance testing, and life cycle acceleration testing to ensure bushings meet specified requirements and perform reliably in their intended applications.