The Unparalleled Advantages of Cast Bronze Sleeve Bearings in Marine Applications

Corrosion Resistance: A Maritime Necessity

In the maritime industry, corrosion is an ever-present adversary. Cast bronze sleeve bearings exhibit remarkable resistance to saltwater corrosion, a property that is paramount for marine equipment. The inherent composition of cast bronze alloys, typically including copper, tin, and sometimes lead, creates a protective patina on the surface. This natural barrier shields the bearing from aggressive corrosive elements, ensuring prolonged functionality in saltwater environments.

Moreover, the corrosion resistance of cast bronze bearings extends beyond mere surface protection. The entire structure of the bearing maintains its integrity even when exposed to constant moisture and salinity. This characteristic is particularly valuable in applications such as propeller shafts, rudder bearings, and stern tubes, where continuous exposure to seawater is inevitable.

Load-Bearing Capacity: Supporting Maritime Might

Marine equipment often operates under substantial loads, and cast bronze sleeve bearings rise to the challenge admirably. These bearings boast an impressive load-bearing capacity, capable of withstanding pressures up to 140 MPa. This robustness is crucial in supporting heavy marine machinery, from massive propeller shafts to intricate steering systems.

The high load-bearing capacity of cast bronze bearings is attributed to their unique microstructure. The alloy composition allows for a perfect balance of hardness and ductility, enabling the bearing to distribute loads evenly across its surface. This property not only enhances the bearing's ability to handle heavy loads but also contributes to its longevity by minimizing wear and deformation under stress.

Self-Lubricating Properties: Smooth Sailing in Challenging Conditions

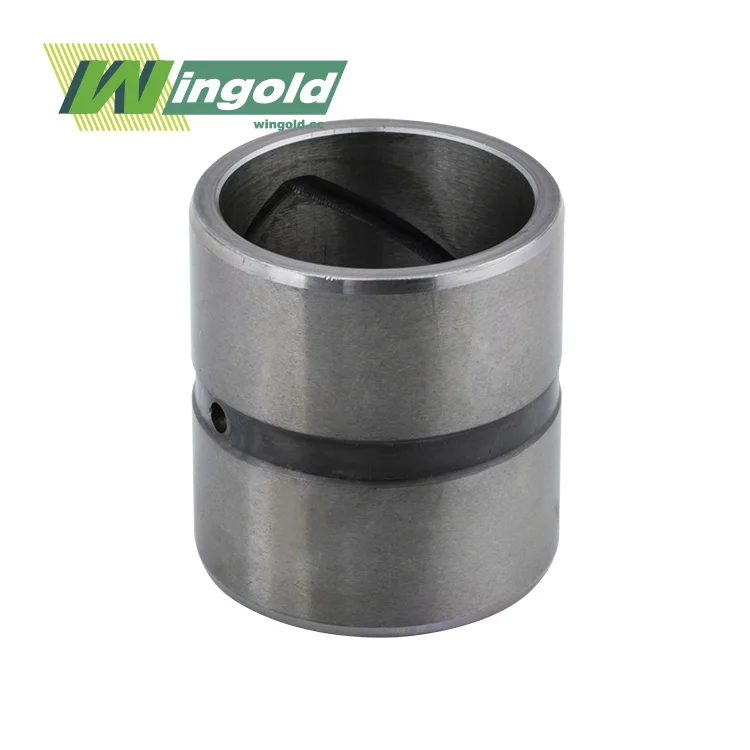

One of the most valuable attributes of cast bronze sleeve bearings in marine applications is their self-lubricating capability. The porous structure of cast bronze allows it to retain oil, creating a reservoir of lubricant within the bearing itself. This feature is particularly beneficial in marine environments where constant lubrication may be challenging to maintain.

The self-lubricating property ensures a consistent film of lubricant between the bearing surfaces, even under varying loads and speeds. This reduces friction, minimizes wear, and prevents metal-to-metal contact, all of which contribute to the extended life of the bearing and the equipment it supports. In marine applications where access for regular maintenance might be limited, this self-lubricating characteristic becomes invaluable, ensuring smooth operation even in remote or hard-to-reach areas of a vessel.

Enhancing Marine Equipment Performance with Cast Bronze Bearings

Thermal Management: Keeping Cool Under Pressure

Efficient heat dissipation is crucial in marine equipment, where overheating can lead to catastrophic failures. Cast bronze sleeve bearings excel in this aspect, thanks to their superior thermal conductivity. The ability to quickly transfer heat away from the bearing surface helps maintain optimal operating temperatures, even under high loads and speeds.

This thermal management capability is particularly beneficial in marine propulsion systems, where bearings are subjected to continuous high-speed rotation and heavy loads. By effectively dissipating heat, cast bronze bearings help prevent thermal expansion, maintain clearances, and ensure consistent performance across a wide range of operating conditions.

Dimensional Stability: Precision in Motion

Marine equipment often requires precise alignment and minimal clearances to function efficiently. Cast bronze sleeve bearings offer excellent dimensional stability, maintaining their shape and size even under varying loads and temperatures. This stability is crucial for applications such as stern tube bearings, where maintaining proper shaft alignment is essential for efficient propulsion and minimizing vibration.

The dimensional stability of cast bronze bearings also contributes to their longevity. By resisting deformation and wear, these bearings maintain their critical dimensions over time, ensuring consistent performance and reducing the need for frequent adjustments or replacements.

Adaptability to Marine Environments

Cast bronze sleeve bearings demonstrate remarkable adaptability to various marine environments. Whether in tropical waters or arctic seas, these bearings maintain their performance characteristics across a wide temperature range, typically from -40°C to 350°C. This versatility makes them suitable for a diverse array of marine applications, from small pleasure craft to large commercial vessels and offshore platforms.

Furthermore, cast bronze bearings can be customized with specific alloy compositions to meet the unique challenges of different marine environments. For instance, bearings used in arctic conditions might incorporate alloys with enhanced low-temperature properties, while those used in tropical climates might focus on maximizing corrosion resistance.

The Future of Cast Bronze Bearings in Marine Technology

Innovations in Alloy Composition

As marine innovation proceeds to advance, so does the improvement of cast bronze combinations for sleeve heading. Analysts and producers are investigating modern compositions that thrust the boundaries of execution, solidness, and natural compatibility. These developments point to make heading that offer indeed more prominent erosion resistance, moved forward load-bearing capacity, and improved self-lubricating properties.

One area of focus is the development of lead-free bronze alloys that maintain the excellent properties of traditional leaded bronzes while meeting increasingly stringent environmental regulations. These new alloys not only address environmental concerns but also often offer improved mechanical properties and corrosion resistance.

Integration with Smart Technologies

The future of cast bronze sleeve orientation in marine applications is likely to include integration with keen innovations. Implanted sensors inside or around the orientation might give real-time information on temperature, stack, and wear, empowering prescient support and optimized execution. This integration of conventional bearing innovation with present day IoT (Web of Things) capabilities seem revolutionize marine gear upkeep and unwavering quality.

Sustainable Manufacturing Processes

As the maritime industry increasingly focuses on sustainability, the manufacturing processes for cast bronze sleeve bearings are also evolving. Innovations in casting techniques, such as improved mold designs and precise control of cooling rates, are leading to bearings with more consistent properties and reduced material waste. Additionally, there's a growing emphasis on using recycled bronze in bearing production, aligning with circular economy principles and reducing the environmental impact of bearing manufacturing.

Conclusion

Cast bronze sleeve bearings are not just essential for marine equipment life; they are at the forefront of innovations that will shape the future of maritime technology. Their unparalleled combination of corrosion resistance, load-bearing capacity, and self-lubricating properties makes them indispensable in ensuring the longevity and reliability of marine equipment. As we look to the future, the continued development of these bearings promises even greater advancements in marine engineering and sustainability.

For more information about our high-quality cast bronze sleeve bearings and how they can enhance your marine equipment's performance and lifespan, please don't hesitate to contact us at info@wingold.cc. Our team of experts is ready to provide you with tailored solutions for your specific marine applications.