The Composition and Properties of Marine-Grade Stainless Steel Sleeve Bearings

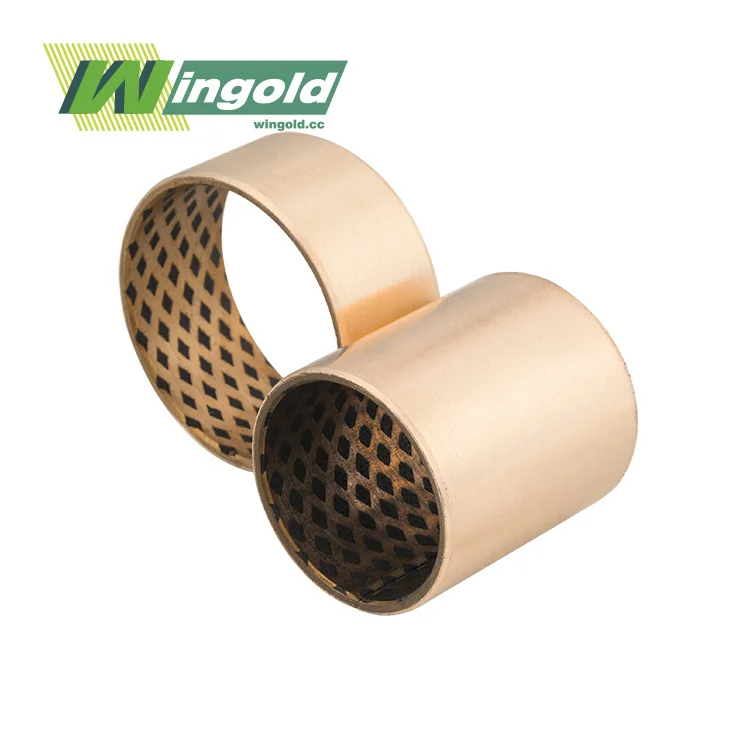

Stainless steel sleeve bearings designed for marine applications boast a sophisticated structure that contributes to their exceptional performance in aquatic environments. The composition typically includes:

- A stainless steel back for structural integrity and corrosion resistance

- A layer of sintered corrosion-resistant alloy powder for enhanced durability

- A PTFE (lead-free) coating for reduced friction and improved wear resistance

This multi-layered structure equips these bearings with a unique set of properties that make them ideal for marine use:

Corrosion Resistance

The use of high-grade stainless steel alloys, such as 316 or 440C, provides exceptional resistance to rust and chemical corrosion. This property is crucial in marine environments where constant exposure to saltwater and humid conditions can rapidly degrade standard bearings.

Load-Bearing Capacity

Despite their compact design, these bearings can withstand significant radial loads. With a maximum load pressure of up to 140N/mm², they can handle the demanding conditions often encountered in marine machinery and equipment.

Temperature Resilience

Marine-grade stainless steel sleeve bearings maintain their performance across a wide temperature range, typically from -195°C to 280°C. This resilience ensures reliable operation in various marine applications, from arctic waters to tropical climates.

Low Friction Performance

The PTFE coating and precision surface finish (Ra 0.1 - 0.8 μm) contribute to a remarkably low friction coefficient, ranging from 0.04 to 0.20. This characteristic reduces wear, extends service life, and improves overall efficiency in marine machinery.

Applications and Advantages of Stainless Steel Sleeve Bearings in Marine Settings

The unique properties of stainless steel sleeve bearings make them invaluable in a wide array of marine applications:

Propulsion Systems

In ship propellers and thrusters, these bearings provide smooth operation and resist the corrosive effects of seawater, ensuring reliable performance even under heavy loads and constant exposure to harsh saltwater environments over extended periods.

Deck Machinery

Winches, cranes, and other deck gear advantage from the tall stack capacity and erosion resistance of stainless steel sleeve orientation, keeping up usefulness in challenging sea conditions.

Steering Systems

The low friction and wear resistance of these bearings contribute to precise and responsive steering mechanisms, crucial for vessel maneuverability and safety.

Offshore Platforms

In seaward oil and gas stages, stainless steel sleeve orientation exceed expectations in different hardware, from pumps to penetrating apparatus, withstanding the cruel combination of saltwater shower and mechanical chemicals.

The advantages of using stainless steel sleeve bearings in these marine applications are numerous:

- Extended service life due to superior corrosion and wear resistance

- Reduced maintenance requirements and associated costs

- Improved equipment reliability and performance in harsh conditions

- Enhanced safety due to consistent operation in critical systems

- Versatility across a wide range of marine machinery and equipment

Maintenance and Longevity of Stainless Steel Sleeve Bearings in Marine Use

While stainless steel sleeve bearings are renowned for their durability in marine environments, proper maintenance can further extend their service life and ensure optimal performance:

Regular Inspection

Periodic visual inspections can help identify early signs of wear or potential issues. Look for any unusual discoloration, pitting, or changes in surface texture that might indicate corrosion or excessive wear.

Lubrication Considerations

Although many stainless steel sleeve bearings are self-lubricating due to their PTFE coating, some applications may benefit from additional lubrication. When lubrication is required, use marine-grade lubricants compatible with the bearing material and suitable for saltwater environments.

Cleaning and Protection

Regular cleaning with fresh water can help remove salt deposits and other contaminants that may accumulate on the bearing surface. After cleaning, apply a thin layer of corrosion-inhibiting oil to protect the bearing during periods of inactivity.

Proper Installation and Alignment

Ensure correct installation and alignment of stainless steel sleeve bearings to prevent uneven wear and premature failure. Proper fitting and alignment contribute significantly to the longevity and performance of these bearings in marine applications.

By adhering to these maintenance practices, marine operators can maximize the lifespan of their stainless steel sleeve bearings, potentially achieving service lives of several years even in the most challenging aquatic environments.

Conclusion

Stainless steel sleeve bearings have proven their worth in marine environments, offering unparalleled performance, durability, and reliability. Their unique composition and properties make them ideally suited to withstand the corrosive effects of saltwater, heavy loads, and extreme temperatures encountered in maritime applications. From propulsion systems to deck machinery, these bearings play a crucial role in ensuring the smooth operation of marine equipment.

As the maritime industry continues to evolve, the demand for high-performance, low-maintenance components like stainless steel sleeve bearings is likely to grow. Their ability to excel in marine environments not only improves equipment reliability but also contributes to enhanced safety and operational efficiency in the challenging world of maritime operations.

For more information about our range of stainless steel sleeve bearings and how they can benefit your marine applications, please contact us at info@wingold.cc. Our team of experts is ready to assist you in finding the perfect bearing solution for your specific needs.