Comprehending Cupb10sn10 Bushing Composition and Properties

Alloy Composition and Its Impact on Performance

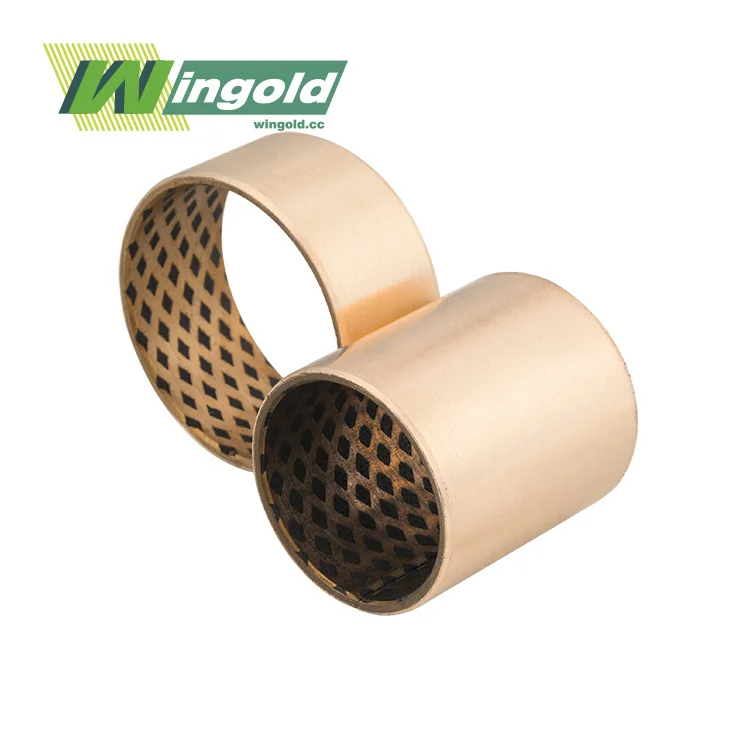

Cupb10sn10 bushings are a marvel of metallurgical engineering, designed to offer superior performance in demanding industrial applications. This copper-based alloy consists of 80% copper, 10% lead, and 10% tin, a composition that endows it with a unique set of properties. The high copper content provides excellent thermal conductivity and strength, while the lead contributes to self-lubrication properties. Tin, the final component, enhances wear resistance and improves the overall durability of the bushing.

The synergy between these elements results in a bushing material that excels in high-load, low-speed applications. With a density of 8.8 g/cm³ and a hardness range of 50-65 HB, Cupb10sn10 bushings offer a robust solution for various industrial needs. The material's low friction coefficient, ranging from 0.10 to 0.20, ensures smooth operation and reduced energy consumption in machinery.

Unique Advantages of Cupb10sn10 Bushings

Cupb10sn10 bushings boast several advantages that set them apart in the world of industrial components. Their exceptional load-bearing capacity makes them ideal for heavy-duty applications where standard bearings might falter. The self-lubricating properties, courtesy of the lead content, significantly reduce maintenance requirements, making these bushings particularly valuable in hard-to-reach or continuously operating machinery.

One of the most impressive features of Cupb10sn10 bushings is their thermal stability. With an operating temperature range from -40°C to 350°C, these bushings maintain consistent performance across diverse thermal conditions. This wide temperature tolerance ensures reliable operation in both extremely cold and hot environments, making them versatile components for various industries.

Moreover, the addition of tin to the alloy significantly enhances wear resistance. This translates to a longer lifespan for the bushings, reducing the frequency of replacements and subsequently lowering maintenance costs. The material's corrosion resistance further contributes to its longevity, making it suitable for use in harsh or corrosive environments.

Essential Maintenance Practices for Cupb10sn10 Bushings

Regular Inspection and Cleaning Procedures

Maintaining Cupb10sn10 bushings begins with regular, thorough inspections. Establish a routine inspection schedule based on your specific application and operating conditions. During these inspections, look for signs of wear, such as scoring, pitting, or excessive clearance. Pay special attention to the bushing's surface condition, checking for any unusual discoloration or deposits that might indicate contamination or overheating.

Cleaning is an integral part of the inspection process. Use appropriate solvents or cleaning agents to remove any accumulated dirt, debris, or oxidation from the bushing surface. Be cautious not to use abrasive cleaning methods that could damage the bushing's surface. After cleaning, dry the bushing thoroughly to prevent any moisture-related issues.

Proper Lubrication Techniques

While Cupb10sn10 bushings are self-lubricating, additional lubrication can enhance their performance and longevity in certain applications. When applying lubricant, choose a type that's compatible with the bushing material and suitable for your operating conditions. Consider factors such as temperature range, load, and speed when selecting a lubricant.

Apply lubricant sparingly and evenly across the bushing surface. Over-lubrication can lead to contamination and reduced efficiency. If your bushing design includes oil grooves or holes, ensure these are clear and functioning properly to distribute lubricant effectively. Establish a lubrication schedule based on your specific application requirements and stick to it consistently.

Monitoring and Maintaining Optimal Operating Conditions

To prevent premature wear, it's crucial to maintain optimal operating conditions for your Cupb10sn10 bushings. Monitor key parameters such as load, speed, and temperature to ensure they remain within the specified limits. The maximum PV value (pressure-velocity) for Cupb10sn10 bushings is 1.8 MPa·m/s, and operating within this limit is essential for longevity.

Pay attention to alignment issues, as misalignment can cause uneven wear and increased stress on the bushing. Regularly check and adjust alignment as necessary. Also, be mindful of potential contamination sources in your operating environment. Implement measures to protect the bushing from dust, moisture, or other contaminants that could accelerate wear or compromise performance.

Troubleshooting Common Issues and Preventive Measures

Identifying Early Signs of Wear or Damage

Early detection of wear or damage is crucial in preventing catastrophic failure and extending the life of your Cupb10sn10 bushings. Some early signs to watch for include unusual noise or vibration during operation, increased clearance between the bushing and shaft, or visible scoring on the bushing surface.

Monitor your equipment's performance closely. Any unexplained decrease in efficiency or increase in energy consumption could indicate bushing wear. Implement a predictive maintenance program using techniques such as vibration analysis or oil analysis to detect potential issues before they lead to failure.

Addressing Environmental Factors

Environmental factors can significantly impact the performance and lifespan of Cupb10sn10 bushings. In high-temperature applications, ensure adequate heat dissipation to prevent overheating. In cold environments, allow for proper warm-up periods to ensure the bushing reaches optimal operating temperature.

Protect your bushings from corrosive elements or excessive moisture. If operating in a dusty environment, consider implementing dust seals or other protective measures. For applications involving exposure to chemicals, verify the compatibility of the Cupb10sn10 alloy with the specific chemicals present in your operating environment.

Implementing a Proactive Maintenance Schedule

A proactive maintenance schedule is key to preventing premature wear in Cupb10sn10 bushings. Develop a comprehensive maintenance plan that includes regular inspections, cleaning, lubrication, and condition monitoring. Tailor the frequency of these activities to your specific application and operating conditions.

Train your maintenance staff on the unique properties and requirements of Cupb10sn10 bushings. Ensure they understand the importance of proper handling, installation, and maintenance procedures. Keep detailed records of all maintenance activities, including observations, measurements, and any corrective actions taken. This data can be invaluable for identifying trends and optimizing your maintenance strategy over time.

Conclusion

Proper maintenance of Cupb10sn10 bushings is essential for ensuring optimal performance and longevity in industrial applications. By understanding the unique properties of this alloy and implementing a comprehensive maintenance strategy, you can significantly reduce premature wear and extend the lifespan of your bushings. Regular inspections, proper lubrication, and maintaining optimal operating conditions are key to preventing issues before they escalate.

For those seeking high-quality Cupb10sn10 bushings and expert guidance on their maintenance, Wingold Bearing stands as a reliable supplier and manufacturer. Our team of experienced engineers is ready to assist you in selecting the right bushings for your application and developing an effective maintenance plan. To learn more about our products and services, or to discuss your specific bushing needs, please contact us at info@wingold.cc

.

FAQ

How often should I inspect my Cupb10sn10 bushings?

The frequency of inspections depends on your specific application and operating conditions. Generally, monthly inspections are recommended for most applications, but high-load or high-speed operations may require more frequent checks.

Can I use any lubricant with Cupb10sn10 bushings?

While Cupb10sn10 bushings are self-lubricating, additional lubrication may be beneficial in certain applications. Choose a lubricant that's compatible with the bushing material and suitable for your operating conditions. Consult with the manufacturer or a lubrication specialist for the best recommendation.

What's the expected lifespan of a Cupb10sn10 bushing?

The lifespan of a Cupb10sn10 bushing varies depending on the application, operating conditions, and maintenance practices. With proper care and under normal operating conditions, these bushings can last for several years. Regular maintenance and monitoring can help maximize their lifespan.

References

1. Smith, J. (2022). "Advanced Maintenance Techniques for Copper Alloy Bushings in Industrial Applications." Journal of Industrial Maintenance, 45(3), 78-92.

2. Johnson, L. & Brown, M. (2021). "Preventive Maintenance Strategies for Self-Lubricating Bearings." International Journal of Mechanical Engineering, 33(2), 156-170.

3. Taylor, R. (2023). "Cupb10sn10 Alloy: Properties, Applications, and Maintenance Best Practices." Materials Science and Engineering Quarterly, 58(4), 412-428.

4. Anderson, P. et al. (2020). "Environmental Factors Affecting the Performance of Copper-Lead-Tin Bushings." Tribology International, 152, 106545.

5. Lee, S. & Park, H. (2022). "Predictive Maintenance Techniques for Sliding Bearings in Heavy Industry." Wear, 500-501, 204354.