The Unique Properties of Brass in High-Temperature Applications

Thermal Conductivity and Heat Dissipation

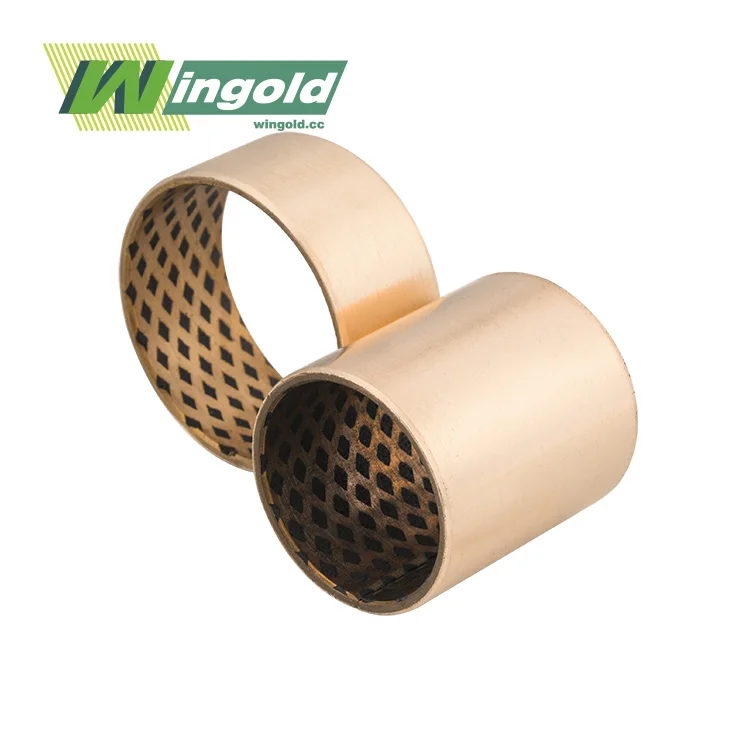

Brass rib orientation has risen as a predominant choice for high-temperature mechanical applications, advertising an interesting combination of solidness, warm conductivity, and execution. These orientations exceed expectations in extraordinarily warm situations due to their remarkable fabric properties, including high warm resistance, a low coefficient of contact, and amazing load-bearing capacity. The inborn characteristics of brass, coupled with the vital rib plan, empower these headings to keep up auxiliary astuteness and operational effectiveness indeed beneath a strongly warm stretch, making them vital in different high-temperature mechanical divisions.

Additionally, the warm development characteristics of brass are profitable in high-heat scenarios. As temperatures change, brass extends and contracts consistently, keeping up appropriate clearances and anticipating seizure or official. This warm steadiness guarantees that the brass spine heading stays operational and dependable indeed when subjected to extraordinary temperature varieties.

Corrosion Resistance in Harsh Environments

High-temperature industries often involve corrosive elements, and brass flange bearings demonstrate exceptional resistance to such harsh conditions. The alloy composition of brass, typically consisting of copper and zinc, forms a protective oxide layer when exposed to air. This natural barrier shields the bearing from corrosive attacks, preserving its structural integrity and functional properties over extended periods.

The corrosion-resistant nature of brass flange bearings is particularly valuable in industries where bearings are exposed to aggressive chemicals or moisture at high temperatures. This resilience translates to reduced maintenance requirements and extended service life, making brass flange bearings a cost-effective solution for demanding industrial applications.

Design Advantages of Flange Bearings in High-Heat Scenarios

Enhanced Load Distribution and Stability

The flange design of these bearings offers significant advantages in high-temperature applications. The integrated flange provides additional surface area for load distribution, enhancing the bearing's ability to handle both radial and axial loads efficiently. This improved load-bearing capacity is crucial in high-heat environments where thermal expansion can exert additional stresses on machinery components.

Furthermore, the flange configuration contributes to increased stability and alignment precision. In high-temperature operations where thermal distortion can be a concern, the flange helps maintain proper positioning of the bearing within its housing. This stability ensures consistent performance and reduces the risk of misalignment-induced wear or failure, even under challenging thermal conditions.

Self-Lubricating Properties for Reduced Maintenance

One of the standout features of brass flange bearings in high-temperature applications is their self-lubricating capability. The alloy composition can be engineered to incorporate solid lubricants within the brass matrix, creating a built-in lubrication system. This self-lubricating property is invaluable in environments where conventional liquid lubricants may break down or evaporate due to extreme heat.

The self-lubricating nature of these bearings ensures consistent, low-friction operation even in the absence of external lubrication. This characteristic not only enhances performance but also significantly reduces maintenance requirements and downtime in high-temperature industrial settings. The elimination of frequent re-lubrication cycles contributes to operational efficiency and cost savings in the long run.

Industry Applications and Performance Benefits

Versatility Across High-Temperature Sectors

Brass flange bearings find extensive application across a wide spectrum of high-temperature industries. In metallurgical operations, these bearings withstand the intense heat of furnaces and rolling mills. The automotive sector relies on brass flange bearings in engine components and exhaust systems where temperatures can soar. Similarly, in the aerospace industry, these bearings prove indispensable in turbine engines and landing gear mechanisms exposed to extreme thermal conditions.

The food processing industry also benefits from the high-temperature capabilities of brass flange bearings, particularly in ovens, dryers, and sterilization equipment. In chemical processing plants, where corrosive environments combine with high temperatures, these bearings demonstrate their resilience and longevity. The versatility of brass flange bearings across these diverse sectors underscores their adaptability and reliability in challenging thermal environments.

Long-Term Performance and Cost-Effectiveness

The superior performance of brass flange bearings in high-temperature applications translates to significant long-term benefits for industries. Their ability to maintain structural integrity and operational efficiency under extreme thermal stress results in extended service life and reduced replacement frequency. This longevity not only minimizes downtime but also contributes to substantial cost savings over the lifecycle of industrial equipment.

Moreover, the self-lubricating properties and corrosion resistance of brass flange bearings lead to reduced maintenance requirements. This aspect is particularly valuable in high-temperature industries where frequent maintenance interventions can be costly and disruptive. By choosing brass flange bearings, industries can optimize their operational efficiency, reduce maintenance overhead, and achieve better overall equipment reliability in challenging thermal environments.

Conclusion

Brass flange bearings have proven themselves as exceptional performers in high-temperature industrial applications. Their unique combination of thermal conductivity, corrosion resistance, and self-lubricating properties makes them ideally suited for extreme heat environments. The flange design further enhances their load-bearing capacity and stability, ensuring reliable operation under challenging conditions. As industries continue to push the boundaries of operational temperatures, brass flange bearings stand out as a robust, efficient, and cost-effective solution for high-heat scenarios.

For more information about our high-quality brass flange bearings and how they can benefit your high-temperature industrial applications, please contact us at info@wingold.cc. Our team of experts is ready to provide you with customized solutions tailored to your specific needs.