- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

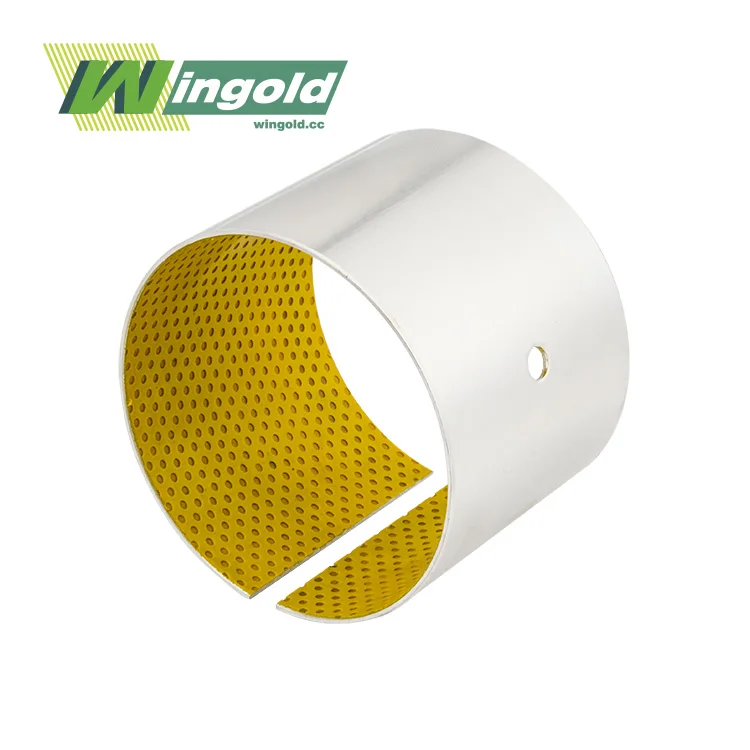

Brass Flange Bearing

Brass Flange Bearings: High-Performance Solutions for Your Industrial Needs

Jiashan Wingold Bearing Co., Ltd. is a leading brass flange bearing manufacturer and supplier. With our cutting-edge technology and years of industry expertise, we offer superior quality products that outperform competitors. Our commitment to innovation, precision engineering, and customer satisfaction makes us the preferred choice for businesses worldwide.

Product Description:

Our products are painstakingly designed to deliver outstanding performance across a diverse range of industrial applications. These bearings are characterized by a robust brass structure with an incorporated flange. This configuration imparts superior load - bearing capabilities and remarkable wear resistance. The self - lubricating features of our products guarantee seamless operation and minimize maintenance needs, rendering them highly suitable for both high - speed and low - speed operational scenarios.

Our Brass Flange Bearing are engineered to endure harsh environments, encompassing corrosive and high - temperature conditions. The distinctive design facilitates straightforward installation and precise alignment, thereby reducing operational downtime and enhancing overall efficiency in your processes. Whether your requirement pertains to standard - sized products or customized solutions, our team of professionals stands ready to fulfill your specific needs.

Specifications:

| Parameter | Value |

|---|---|

| Material | High-grade brass alloy |

| Flange Type | Plain, Grooved, or Custom |

| Inner Diameter | 5mm - 100mm |

| Outer Diameter | 8mm - 150mm |

| Length | 10mm - 200mm |

| Load Capacity | Up to 5000 N |

| Operating Temperature | -40°C to 250°C |

| Lubrication | Self-lubricating or oil-impregnated |

Why Choose Us?

- Over 20 years of industry experience

- State-of-the-art manufacturing facilities

- Rigorous quality control processes

- Customization capabilities to meet unique requirements

- Competitive pricing without compromising on quality

- Excellent customer support and technical assistance

- Fast turnaround times and reliable delivery

- Commitment to sustainable and eco-friendly practices

Material:

Our brass flange bearings are crafted from high-grade brass alloy, carefully selected for its superior properties. This material offers excellent corrosion resistance, high thermal conductivity, and outstanding machining characteristics. The brass composition is optimized to provide the perfect balance between strength and self-lubrication, ensuring long-lasting performance in demanding applications.

Product Advantages:

- Superior Load Capacity: Our products are engineered to handle heavy radial and axial loads, making them suitable for a wide range of industrial applications. The integrated flange design provides additional support and stability, enhancing overall performance.

- Self-Lubricating Properties: The unique composition of our brass alloy allows for self-lubrication, reducing friction and wear. This feature extends the bearing's lifespan and minimizes maintenance requirements, resulting in lower operational costs for our customers.

- Excellent Thermal Management: Brass's high thermal conductivity enables efficient heat dissipation, preventing overheating and ensuring consistent performance even in high-temperature environments.

- Corrosion Resistance: Our products offer exceptional resistance to corrosion, making them ideal for use in challenging environments where moisture or chemical exposure is a concern.

- Precision Engineering: Each bearing is manufactured to tight tolerances, ensuring optimal fit and alignment in your machinery. This precision contributes to reduced vibration, smoother operation, and improved overall equipment efficiency.

Application Areas:

- Automotive Sector: Components within transmission systems, steering mechanisms, and suspension assemblies.

- Aerospace Industry: Landing gear components, flight control systems, and hydraulic actuator units.

- Marine Equipment Domain: Propeller shaft arrangements, rudder systems, and deck - mounted machinery.

- Construction Machinery Field: Excavator equipment, bulldozer machinery, and crane systems.

- Agriculture Sector: Tractor units, harvester machinery, and irrigation system components.

- Material Handling Industry: Conveyor systems, lift equipment, and packaging machinery.

- Food Processing Industry: Mixing equipment, grinding machinery, and packaging apparatus.

- Textile Machinery Industry: Spinning frame equipment, weaving loom machinery, and knitting machine units.

- Printing Press Industry: Paper - feeding mechanisms and roller bearing components.

- Renewable Energy Industry: Wind turbine installations and solar tracking systems.

Quality Control:

We implement rigorous quality control measures throughout our production process.

Factory related:

Provide suitable bearing products and supporting services according to the needs of different customers

Packaging and Transportation:

We ensure secure packaging and reliable shipping for all orders.

Shipping Samples:

Sample orders are available for testing and evaluation.

Qualification Certification:

We hold ISO 9001 certification for quality management.

Production process related:

Select appropriate raw materials to produce bearing products that meet technical requirements

Exhibitions:

We regularly participate in international trade shows to showcase our products.

FAQ:

- What is the minimum order quantity for the Brass Flange Bearing?

Our minimum order quantity is typically 100 pieces, but we can be flexible depending on your specific needs. - Can you provide custom designs for the products?

Yes, we offer customization services to meet your unique requirements. Our engineering team will work closely with you to develop the perfect solution. - What is the lead time for standard products?

Standard sizes usually have a lead time of 2-3 weeks. For custom orders, lead times may vary depending on the complexity of the design. - Do you offer any warranty on your products?

Yes, we provide a 12-month warranty on all our standard products. Extended warranties are available for certain applications. - How do I determine the right size and type of the product for my application?

Our technical team can assist you in selecting the most suitable bearing based on your application requirements. Please provide us with details such as load, speed, and operating conditions.

Contact Us:

For more information about our brass flange bearings or to discuss your specific needs, please contact us at info@wingold.cc. Our team of experts is ready to provide you with the best bearing solutions for your industrial applications.

Learn about our latest products and discounts through SMS or email