Understanding CuPb10Sn10 Bushings and Their Applications

Composition and Properties of CuPb10Sn10 Alloy

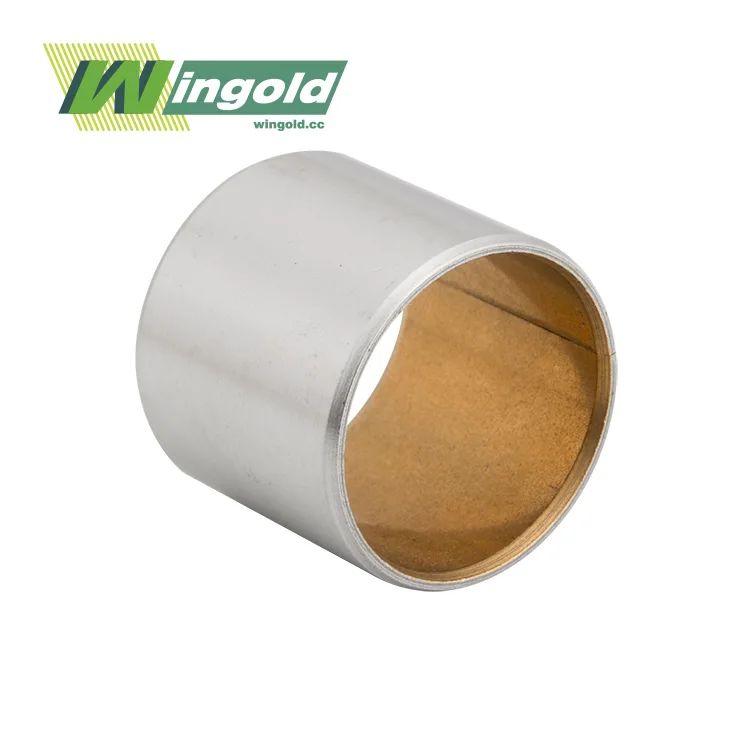

CuPb10Sn10 bushings are crafted from a specialized copper-lead-tin alloy, boasting a unique composition that offers exceptional performance characteristics. This alloy consists of 80% copper, 10% lead, and 10% tin, creating a material with remarkable properties suited for demanding industrial applications. The copper base provides strength and thermal conductivity, while the lead component contributes self-lubricating properties, and tin enhances wear resistance.

These bushings exhibit a density of approximately 8.8 g/cm³ and a hardness range of 50-65 HB. Their maximum PV value (pressure-velocity) reaches 1.8 MPa·m/s, indicating their capability to handle high loads at low speeds. Moreover, CuPb10Sn10 bushings maintain their performance across a wide temperature spectrum, from -40°C to 350°C, showcasing impressive thermal stability.

Advantages in Industrial Applications

The unique composition of CuPb10Sn10 bushings translates into several advantages for industrial use. Their superior load-bearing capacity makes them ideal for heavy-duty machinery and equipment subjected to intense pressures. The self-lubricating nature of these bushings, attributed to the lead content, significantly reduces maintenance requirements and extends operational life, particularly in environments where regular lubrication is challenging.

Furthermore, the excellent wear resistance imparted by the tin component ensures longevity, minimizing the frequency of replacements and associated downtime. The bushings' ability to operate effectively across a broad temperature range makes them versatile components suitable for diverse industrial settings, from freezing cold to extremely hot environments.

Common Uses in Various Industries

CuPb10Sn10 bushings find widespread application across numerous industries due to their robust performance characteristics. In the automotive sector, these bushings are frequently employed in suspension systems, steering mechanisms, and engine components. The marine industry utilizes them in propeller shafts and rudder bearings, capitalizing on their corrosion resistance and self-lubricating properties in harsh saline environments.

In the realm of heavy machinery, CuPb10Sn10 bushings play crucial roles in construction equipment, such as excavators and bulldozers, where they endure high loads and abrasive conditions. The aerospace industry also benefits from these bushings in landing gear assemblies and control surface hinges, where reliability under extreme conditions is paramount.

Moreover, these versatile components are integral to various manufacturing processes, finding use in metalworking machinery, textile equipment, and food processing plants. Their ability to operate without external lubrication makes them particularly valuable in clean environments where oil contamination must be avoided, such as in pharmaceutical and electronics manufacturing.

Preparation and Tools Required for CuPb10Sn10 Bushing Installation

Essential Tools and Equipment

Proper installation of CuPb10Sn10 bushings necessitates a specific set of tools and equipment to ensure precision and efficiency. A caliper or micrometer is indispensable for accurate measurement of both the bushing and the housing dimensions. A hydraulic or mechanical press is often required for inserting the bushing into its housing, especially for larger or tighter-fitting components.

Additionally, you'll need a set of mandrels or arbor press attachments that match the bushing dimensions to apply even pressure during installation. For cleaning and deburring, have on hand a selection of fine-grit sandpaper, emery cloth, and a deburring tool. A dial indicator can be useful for checking alignment during and after installation.

Safety Precautions and Personal Protective Equipment

Safety should be paramount when working with CuPb10Sn10 bushings and the associated installation equipment. Always wear appropriate personal protective equipment (PPE), including safety glasses to shield your eyes from metal particles or debris. Gloves are essential to protect your hands from sharp edges and to maintain cleanliness of the components.

If using a press or other power tools, hearing protection may be necessary. Ensure your work area is well-ventilated, particularly if any cleaning solvents are used. Be mindful of proper lifting techniques when handling heavy components or equipment to prevent strain or injury.

Preparing the Work Environment

Creating an optimal work environment is crucial for successful CuPb10Sn10 bushing installation. Begin by thoroughly cleaning your workspace to prevent contamination of the bushing or housing. Adequate lighting is essential for precise measurements and alignment checks.

Organize your tools and materials in a logical manner to streamline the installation process. If possible, set up a dedicated area for measuring and another for the actual installation. Ensure you have a stable, level surface for your press or installation equipment. Keep a clean, lint-free cloth and appropriate cleaning solvents on hand for final cleaning of components before assembly.

Step-by-Step Installation Process for CuPb10Sn10 Bushings

Inspection and Measurement

Begin the installation process with a thorough inspection of both the CuPb10Sn10 bushing and the housing. Check for any signs of damage, deformation, or contamination. Using your caliper or micrometer, carefully measure the outer diameter of the bushing and the inner diameter of the housing. Verify that these measurements align with the specifications provided by the manufacturer.

Pay particular attention to the interference fit requirements. CuPb10Sn10 bushings typically require a specific interference fit to function optimally. Consult the manufacturer's guidelines to ensure the dimensions fall within the acceptable range for your application.

Preparation of the Housing

Proper preparation of the housing is crucial for a successful installation. Start by thoroughly cleaning the housing bore using an appropriate solvent to remove any dirt, oil, or debris. Once clean, inspect the bore for any burrs, nicks, or irregularities that could interfere with the bushing installation.

If necessary, use fine-grit sandpaper or a honing tool to smooth out any imperfections in the bore. Be cautious not to remove too much material, as this could affect the interference fit. After smoothing, clean the bore again to remove any residual particles.

Bushing Insertion Technique

With the housing prepared, you're ready to insert the CuPb10Sn10 bushing. If the bushing is being installed at room temperature, you may need to use a press to achieve proper insertion. Align the bushing carefully with the housing bore, ensuring it's square to the opening.

Use an appropriately sized mandrel or arbor press attachment that contacts the bushing's face evenly. Apply steady, consistent pressure to press the bushing into place. Avoid using excessive force, which could damage the bushing or deform the housing. If you encounter significant resistance, stop and reassess the fit and alignment.

Post-Installation Checks and Adjustments

After inserting the CuPb10Sn10 bushing, conduct a series of checks to ensure proper installation. Verify that the bushing is fully seated and flush with the housing surface. Use a dial indicator to check for any runout or misalignment.

If your application requires specific internal clearances, measure the inner diameter of the installed bushing to confirm it meets specifications. Some applications may require reaming of the bushing after installation to achieve the final desired internal diameter.

Finally, clean the installed bushing thoroughly to remove any debris or particles introduced during the installation process. If specified by the manufacturer or required by your application, apply any necessary lubricants or treatments to the bushing surface.

Conclusion

Installing CuPb10Sn10 bushings correctly is a critical process that demands attention to detail and adherence to best practices. By following this comprehensive guide, you can ensure optimal performance and longevity of these high-performance components in your industrial applications. Remember that proper installation is key to harnessing the full potential of CuPb10Sn10 bushings, including their superior load capacity, self-lubricating properties, and excellent wear resistance.

If you have any further questions about CuPb10Sn10 bushings or need assistance with your specific application, don't hesitate to reach out to our team of experts at Wingold Bearing. Contact us at info@wingold.cc for personalized support and solutions tailored to your industrial needs.

FAQs

How often should CuPb10Sn10 bushings be replaced?

The lifespan of CuPb10Sn10 bushings varies depending on the application and operating conditions. Regular inspections are recommended, and replacement should be considered when signs of wear or performance degradation are observed.

Can CuPb10Sn10 bushings be used in high-temperature environments?

Yes, these bushings can operate effectively in temperatures ranging from -40°C to 350°C, making them suitable for many high-temperature applications.

Are CuPb10Sn10 bushings environmentally friendly?

While they contain lead, which can be an environmental concern, their self-lubricating properties reduce the need for additional lubricants, potentially decreasing overall environmental impact in certain applications.