Understanding POM Coated Washers: Composition and Properties

The Structure of POM Coated Washers

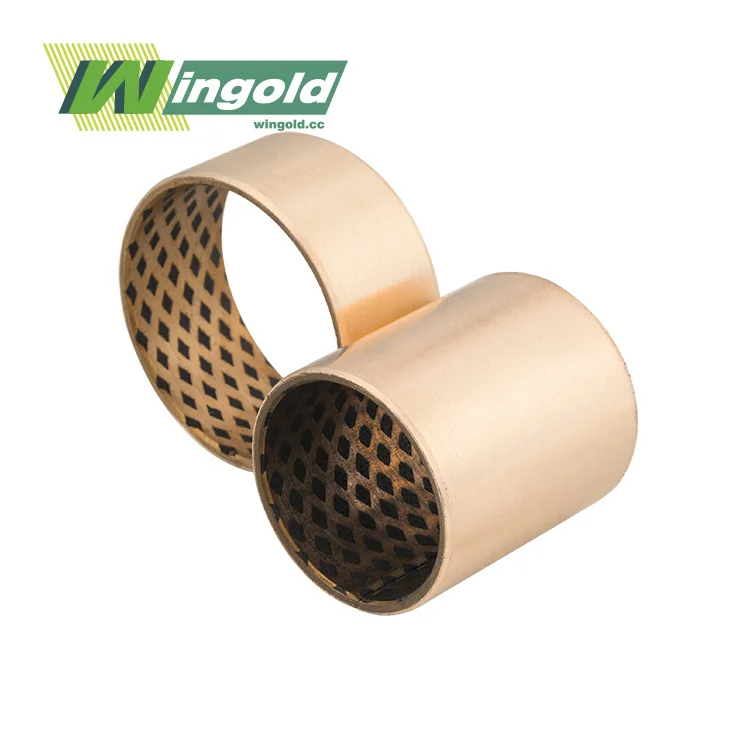

POM coated washers are meticulously engineered components designed for superior performance in diverse industrial applications. At their core, these washers feature a high-grade steel back, providing strength and durability. The steel core is then coated with a layer of polyoxymethylene (POM), a thermoplastic polymer renowned for its exceptional mechanical properties.

The structure of these washers typically consists of three layers:

- Steel back: Provides structural integrity and load-bearing capacity

- Sintered porous bronze powder: Acts as an intermediate layer, enhancing adhesion and performance

- Modified polyformaldehyde (POM) coating: Offers low friction and self-lubricating properties

This unique composition allows POM composite bushings and coated washers to combine the strength of steel with the low-friction benefits of POM, creating versatile and efficient components for machinery applications.

Key Properties of POM Coated Washers

POM coated washers boast an impressive array of properties that contribute to their efficiency-enhancing capabilities:

- Low Friction Coefficient: The POM coating provides a surface with remarkably low friction, typically ranging from 0.05 to 0.25. This property is crucial for reducing wear and energy consumption in machinery.

- High Load Capacity: These washers can withstand maximum load pressures of up to 70N/mm², making them suitable for demanding applications.

- Wide Temperature Range: POM coated washers maintain their performance across a broad temperature spectrum, from -40°C to 130°C, ensuring reliability in various operating conditions.

- Excellent PV Value: With a maximum allowable PV (pressure-velocity) value of 22N/mm²·m/s in dry conditions, these washers can handle high loads and speeds simultaneously.

- High Sliding Speed: They can accommodate sliding speeds of up to 2.5m/s, making them ideal for high-speed machinery applications.

These properties collectively contribute to the enhanced efficiency and performance of machinery equipped with POM coated washers.

Mechanisms of Efficiency Improvement

Friction Reduction and Its Impact

The primary mechanism through which POM coated washers improve machinery efficiency is friction reduction. The low-friction surface of the POM coating minimizes resistance between moving parts, leading to several benefits:

- Decreased Energy Consumption: Lower friction translates to reduced energy requirements for operating machinery, resulting in improved energy efficiency and lower operational costs.

- Minimized Heat Generation: Reduced friction means less heat is generated during operation, preventing overheating and potential damage to machinery components.

- Smoother Operation: The low-friction surface promotes smoother movement between parts, reducing vibrations and enhancing overall machinery performance.

Self-Lubricating Properties and Maintenance Reduction

Another crucial aspect of the efficiency-enhancing capabilities of POM coated washers and self lubricating bushings is their inherent self-lubricating nature. This property offers several advantages:

- Elimination of External Lubrication: The self-lubricating POM coating eliminates the need for constant application of external lubricants, reducing maintenance requirements and associated costs.

- Consistent Performance: Unlike traditional lubricants that can degrade or become contaminated over time, the self-lubricating properties of POM coated washers remain consistent throughout their lifespan.

- Environmental Benefits: By reducing or eliminating the need for external lubricants, POM coated washers contribute to a cleaner and more environmentally friendly operation.

Wear Resistance and Longevity

POM coated washers significantly enhance machinery efficiency through their exceptional wear resistance and longevity:

- Extended Component Lifespan: The wear-resistant POM coating protects the underlying steel core, extending the overall lifespan of the washer and the machinery it's used in.

- Reduced Downtime: With increased durability, machinery equipped with POM coated washers requires less frequent replacements, minimizing downtime and maintaining operational efficiency.

- Consistent Performance: As these washers maintain their properties over extended periods, they ensure consistent machinery performance, preventing gradual efficiency loss due to component wear.

Applications and Industries Benefiting from POM Coated Washers

Automotive Manufacturing

In the automotive industry, POM coated washers play a crucial role in enhancing efficiency and performance:

- Engine Components: Used in various engine parts to reduce friction and improve fuel efficiency.

- Suspension Systems: Incorporated in suspension components to enhance smooth operation and reduce wear.

- Transmission Systems: Applied in gearboxes and transmission assemblies to minimize energy loss and extend component lifespan.

Aerospace Applications

The aerospace sector leverages the benefits of POM coated washers in several critical areas:

- Aircraft Control Systems: Used in control surface mechanisms to ensure smooth and precise movements.

- Landing Gear: Incorporated in landing gear assemblies to withstand high loads and provide reliable performance.

- Cabin Interior Components: Applied in various cabin fixtures to reduce noise and vibration, enhancing passenger comfort.

Heavy Machinery and Industrial Equipment

POM coated washers find extensive use in heavy machinery and industrial equipment:

- Hydraulic and Pneumatic Systems: Used in cylinders and valves to improve seal performance and reduce friction.

- Conveyor Systems: Applied in bearing housings and rollers to enhance smooth operation and reduce maintenance needs.

- Mining Equipment: Incorporated in various components to withstand harsh environments and heavy loads while maintaining efficiency.

Textile Machinery

The textile industry benefits from POM coated washers in several ways:

- Spinning Machines: Used in various rotating components to reduce friction and improve yarn quality.

- Weaving Looms: Applied in shuttle mechanisms and other moving parts to enhance smooth operation and reduce wear.

- Knitting Machines: Incorporated in needle beds and cam systems to improve precision and reduce maintenance requirements.

Food Processing Equipment

In the food processing industry, POM coated washers offer unique advantages:

- Mixing Equipment: Used in mixer bearings and seals to provide smooth operation in hygiene-critical environments.

- Packaging Machinery: Applied in various moving components to enhance efficiency and reduce the risk of contamination.

- Conveyor Systems: Incorporated in food-grade conveyor bearings to ensure reliable performance and easy cleaning.

Conclusion

POM coated washers have proven to be invaluable components in enhancing machinery efficiency across a wide range of industries. Their unique combination of a steel core and POM coating offers an optimal balance of strength, low friction, and self-lubricating properties. By reducing friction, minimizing wear, and extending equipment lifespan, these washers contribute significantly to improved operational efficiency, reduced maintenance costs, and enhanced overall performance of machinery.

As industries continue to seek ways to optimize their processes and reduce operational costs, the adoption of POM coated washers presents a compelling solution. Their versatility, durability, and efficiency-enhancing properties make them an excellent choice for various applications, from automotive manufacturing to food processing equipment.

If you're looking to improve the efficiency of your machinery and reduce maintenance costs, consider incorporating POM coated washers into your equipment. As a leading POM coated washer supplier and manufacturer, Wingold Bearing offers a wide range of high-quality, customizable options to meet your specific needs. Contact us at info@wingold.cc to learn more about how our POM coated washers can benefit your operations and take your machinery efficiency to the next level.

Frequently Asked Questions

What makes POM coated washers different from traditional washers?

POM coated washers feature a unique steel core with a polyoxymethylene coating, offering low friction and self-lubricating properties that traditional washers lack.

Can POM coated washers be used in high-temperature environments?

Yes, these washers can operate effectively in temperatures ranging from -40°C to 130°C, making them suitable for various industrial applications.

How do POM coated washers contribute to energy efficiency?

By reducing friction between moving parts, POM coated washers minimize energy loss, leading to improved overall energy efficiency in machinery.

Are POM coated washers suitable for food processing equipment?

Yes, POM coated washers are often used in food processing equipment due to their self-lubricating properties and ability to operate in hygiene-critical environments.