The Unique Composition and Properties of CuPb10Sn10 Bimetallic Bearings

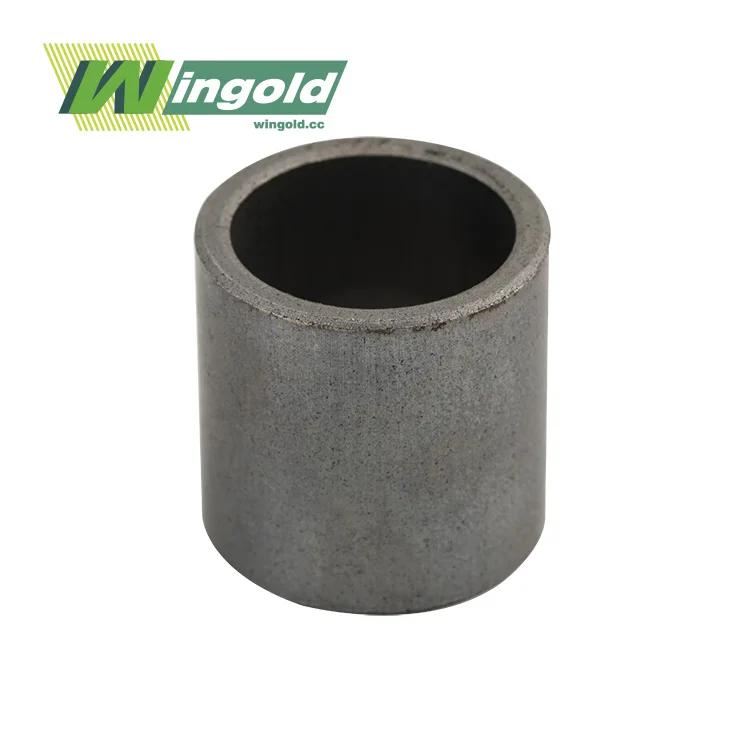

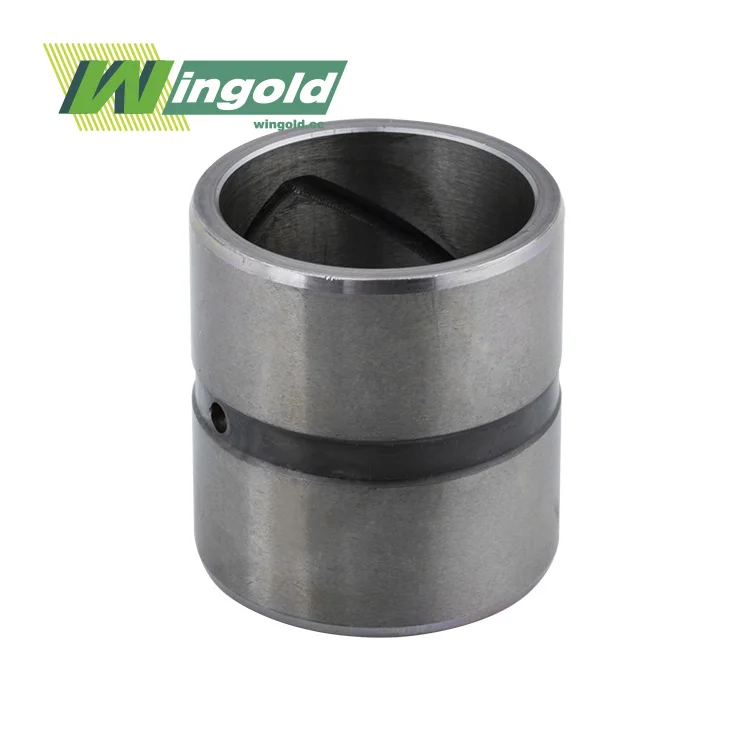

CuPb10Sn10 bimetallic bearings are engineered to provide optimal performance in challenging industrial applications. The composition of these bearings is carefully designed to maximize their effectiveness and longevity.

Material Composition

The CuPb10Sn10 alloy used in these bimetallic bearings consists of 80% copper, 10% lead, and 10% tin. This unique combination creates a self-lubricating surface that significantly reduces friction and wear. The steel backing provides structural integrity and excellent heat dissipation properties, enhancing the overall performance of the bearing.

Key Properties

CuPb10Sn10 bimetallic bearings boast several key properties that set them apart from other bearing materials:

- Superior Load Capacity: The steel backing combined with the copper-lead-tin alloy can support heavy radial and axial loads without deformation.

- Excellent Wear Resistance: The self-lubricating properties of the alloy minimize wear, even in boundary lubrication conditions.

- Enhanced Thermal Management: The high copper content ensures efficient heat dissipation, maintaining optimal operating temperatures.

- Corrosion Resistance: The alloy composition provides good resistance to corrosive environments.

- Low Friction Performance: The inherent lubricity of the lead component reduces friction, improving energy efficiency.

- Conformability: The soft alloy lining can adapt to minor misalignments or shaft irregularities, ensuring even load distribution.

Operating Parameters

CuPb10Sn10 bimetallic bearings are designed to operate effectively under a wide range of conditions:

- Inner Diameter: 20-500 mm

- Wall Thickness: 1-10 mm

- Length: Up to 1000 mm

- Operating Temperature: -40°C to 150°C

- Maximum Load Capacity: Up to 140 MPa

- Hardness (HB): 50-65

Comparative Analysis: CuPb10Sn10 Bimetallic Bearings vs. Other Materials

To truly appreciate the advantages of CuPb10Sn10 bimetallic bearings, it's essential to compare them with other common bearing materials.

CuPb10Sn10 vs. Bronze Bearings

Bronze bearings have been a popular choice for many years due to their good wear resistance and load-bearing capacity. However, CuPb10Sn10 bimetallic bearings offer several advantages:

- Higher Load Capacity: The steel backing of CuPb10Sn10 bearings allows them to support heavier loads compared to solid bronze bearings.

- Better Conformability: The softer CuPb10Sn10 lining can adapt to minor misalignments more effectively than bronze.

- Improved Thermal Management: The steel backing of CuPb10Sn10 bearings dissipates heat more efficiently than solid bronze.

- Enhanced Self-Lubrication: The lead content in CuPb10Sn10 bearings provides superior self-lubricating properties compared to bronze.

CuPb10Sn10 vs. Plain Steel Bearings

Plain steel bearings are known for their high load capacity and durability. However, bimetallic self lubricating bearing offers several advantages:

- Lower Friction: The CuPb10Sn10 alloy provides significantly lower friction compared to plain steel, reducing energy consumption and wear.

- Better Wear Resistance: The self-lubricating properties of CuPb10Sn10 bearings result in less wear compared to plain steel bearings, especially in boundary lubrication conditions.

- Improved Conformability: CuPb10Sn10 bearings can adapt to minor misalignments better than rigid steel bearings, reducing the risk of edge loading.

- Corrosion Resistance: CuPb10Sn10 bearings offer better corrosion resistance compared to plain steel bearings, especially in humid or corrosive environments.

CuPb10Sn10 vs. Plastic Bearings

Plastic bearings are often chosen for their low cost and corrosion resistance. However, CuPb10Sn10 bimetallic bearings offer several advantages in high-load applications:

- Higher Load Capacity: CuPb10Sn10 bearings can support much higher loads than plastic bearings.

- Better Temperature Resistance: CuPb10Sn10 bearings can operate at higher temperatures compared to most plastic bearings.

- Improved Dimensional Stability: CuPb10Sn10 bearings maintain their dimensions better under load and at elevated temperatures compared to plastic bearings.

- Longer Lifespan: In high-load applications, CuPb10Sn10 bearings typically outlast plastic bearings due to their superior wear resistance.

Applications and Industries Benefiting from CuPb10Sn10 Bimetallic Bearings

The unique properties of CuPb10Sn10 bimetallic bearings make them ideal for a wide range of industrial applications, particularly in high-load, low-speed environments.

Heavy Machinery

CuPb10Sn10 bimetallic bearings are extensively used in heavy machinery due to their high load capacity and wear resistance. Common applications include:

- Hydraulic and pneumatic equipment

- Forging and pressing machine tools

- Lifting and handling machinery

- Port machinery

Automotive and Transportation

In the automotive and transportation sectors, CuPb10Sn10 bimetallic bearings find applications in:

- Engine components (e.g., connecting rods, camshafts)

- Transmission systems

- Suspension systems

- Railway locomotives

Industrial Manufacturing

Various manufacturing industries benefit from the use of CuPb10Sn10 bimetallic bearings, including:

- Textile machinery

- Food processing equipment

- Chemical processing machinery

- Papermaking machinery

- Metallurgical equipment

Marine and Offshore

The corrosion resistance and high load capacity of CuPb10Sn10 bimetallic bearings make them suitable for marine and offshore applications, such as:

- Shipbuilding components

- Offshore drilling equipment

- Marine propulsion systems

Conclusion

CuPb10Sn10 bimetallic bearings offer a compelling combination of properties that make them superior to many traditional bearing materials in high-load, low-speed applications. Their unique composition provides excellent load capacity, wear resistance, and thermal management, while also offering the benefits of self-lubrication and conformability. These characteristics make CuPb10Sn10 bimetallic bearings an ideal choice for a wide range of industries, from heavy machinery to automotive and marine applications.

For those seeking a reliable and high-performance bearing solution, CuPb10Sn10 bimetallic bearings, including bimetallic bushing sleeves, from a reputable supplier or manufacturer like Wingold Bearing are worth considering. Our expertise in custom bearing solutions ensures that you receive the optimal product for your specific needs. To learn more about how CuPb10Sn10 bimetallic bearings can benefit your application or to discuss your bearing requirements, please contact us at info@wingold.cc.

FAQ

What are the main advantages of CuPb10Sn10 bimetallic bearings?

CuPb10Sn10 bimetallic bearings offer superior load capacity, excellent wear resistance, enhanced thermal management, corrosion resistance, low friction performance, and good conformability.

In which industries are CuPb10Sn10 bimetallic bearings commonly used?

These bearings are widely used in heavy machinery, automotive and transportation, industrial manufacturing, and marine and offshore applications.

How do CuPb10Sn10 bimetallic bearings compare to bronze bearings?

CuPb10Sn10 bimetallic bearings generally offer higher load capacity, better conformability, improved thermal management, and enhanced self-lubrication compared to bronze bearings.

References

1. Zhang, H., & Li, Q. (2022). Tribological Performance of CuPb10Sn10 Bimetallic Bearings under High Load Conditions. Journal of Materials Engineering and Performance, 31(8), 5621–5630.

2. Kim, S., & Park, J. (2021). Comparative Study on Cu-Based Bearing Alloys for Industrial Applications. Wear, 490–491, 204200.

3. Wang, Y., & Chen, L. (2023). Influence of Lead and Tin Content on the Mechanical Properties of Copper-Based Bearing Materials. Materials Science Forum, 1078, 145–152.

4. Singh, R., & Gupta, D. (2020). Advancements in Bimetallic Bearing Design for Heavy Machinery Applications. Tribology International, 151, 106505.

5. Wingold Bearing Co., Ltd. (2024). CuPb10Sn10 Bimetallic Bearings Technical Datasheet.