The Science Behind Sintered Bearings and Their High-Temperature Capabilities

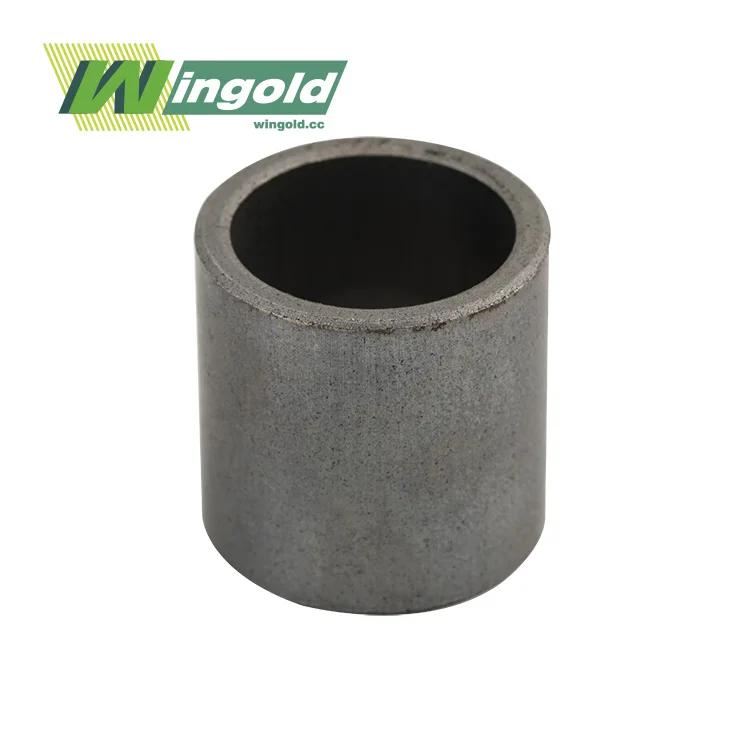

Sintered bearings represent a pinnacle of engineering innovation, particularly when it comes to high-temperature applications. These bearings are manufactured through a sophisticated process known as powder metallurgy, which involves compressing metal powders and heating them to just below their melting point. This process results in a unique porous structure that sets sintered bearings apart from their conventional counterparts.

The porosity of sintered bearings plays a crucial role in their high-temperature performance. These microscopic pores act as reservoirs for sintered bearing oil, allowing the bearing to maintain lubrication even under extreme heat. The oil is carefully selected for its thermal stability and ability to maintain viscosity at elevated temperatures, ensuring consistent performance across a wide temperature range.

Moreover, the metal matrix of sintered bearings can be tailored to include specific alloys that enhance heat resistance and durability. Common materials used in high-temperature sintered bearings include bronze, iron, and various specialty alloys. These materials are chosen for their ability to maintain structural integrity and dimensional stability even when subjected to thermal cycling and prolonged exposure to high temperatures.

Thermal Expansion and Dimensional Stability

One of the key challenges in high-temperature applications is managing thermal expansion. Sintered bearings excel in this area due to their unique composition and manufacturing process. The controlled porosity allows for some flexibility in the bearing structure, which can accommodate thermal expansion without compromising the bearing's performance or causing undue stress on surrounding components.

Additionally, the sintering process allows for precise control over the final dimensions of the bearing. This precision is maintained even at high temperatures, ensuring that the bearing continues to operate within specified tolerances. The dimensional stability of sintered bearings at elevated temperatures is a significant factor in their ability to revolutionize high-temperature applications, as it allows for more reliable and consistent operation in environments where traditional bearings might fail.

Advantages of Sintered Bearings in High-Temperature Environments

The use of sintered bearings in high-temperature environments offers a multitude of advantages that have transformed various industries. These benefits stem from the unique properties of sintered bearings and their specialized sintered bearing oil.

One of the primary advantages is the exceptional self-lubricating capability of sintered bearings. The porous structure, impregnated with high-quality sintered bearing oil, provides continuous lubrication without the need for external lubrication systems. This self-lubricating feature is particularly valuable in high-temperature applications where conventional lubricants might break down or evaporate quickly.

Another significant advantage of sintered steel bushings is the reduced friction and wear in high-temperature conditions. The sintered bearing oil used in these bushings is formulated to maintain its lubricating properties even at extreme temperatures. This ensures smoother operation, reduced energy consumption, and extended component life—all crucial factors in high-temperature industrial applications.

Maintenance and Cost Benefits

The self-lubricating nature of sintered bearings translates into substantial maintenance and cost benefits. In high-temperature environments, where accessing components for regular maintenance can be challenging and costly, the reduced need for lubrication and replacement is a significant advantage. This leads to decreased downtime, lower maintenance costs, and improved overall efficiency of operations.

Furthermore, the longevity of sintered bearings in high-temperature applications contributes to a lower total cost of ownership. While the initial investment in sintered bearings might be higher compared to conventional options, their extended service life and reduced maintenance requirements often result in significant long-term savings.

Applications and Industries Benefiting from High-Temperature Sintered Bearings

The revolutionary capabilities of oil impregnated brass bushings, as a type of sintered bearing, in high-temperature environments have found applications across a wide spectrum of industries. These bushings, enhanced with specialized sintered bearing oil, have become integral components in numerous high-temperature applications.

In the automotive industry, sintered bearings are used in turbochargers, exhaust gas recirculation systems, and other high-temperature engine components. Their ability to withstand extreme heat while providing consistent lubrication has led to improved engine efficiency and durability.

The aerospace sector has also embraced sintered bearings for use in jet engines, where temperatures can reach extreme levels. The reliability and performance of these bearings under such conditions have contributed to advancements in aircraft engine design and efficiency.

Industrial and Energy Sector Applications

In the industrial sector, sintered bearings have found applications in high-temperature furnaces, kilns, and ovens. Their ability to maintain dimensional stability and lubrication at elevated temperatures makes them ideal for use in equipment that operates in these harsh environments.

The energy sector, particularly in power generation, has benefited from the use of sintered bearings in turbines and generators. These components often operate at high temperatures and speeds, conditions where sintered bearings excel due to their self-lubricating properties and heat resistance.

Additionally, the chemical and petrochemical industries utilize sintered bearings in pumps and processing equipment that handle hot fluids or operate in high-temperature environments. The corrosion resistance of certain sintered bearing materials, combined with their high-temperature capabilities, makes them particularly suitable for these challenging applications.

Conclusion

Sintered bearings have truly revolutionized high-temperature applications across various industries. Their unique properties, enhanced by specialized sintered bearing oil, have opened new possibilities in machinery design and operation. As industries continue to push the boundaries of performance and efficiency, the demand for high-quality sintered bearings is likely to grow.

For those seeking reliable sintered bearing solutions for high-temperature applications, Wingold Bearing stands as a trusted manufacturer and supplier. Our expertise in sliding bearing technology and commitment to innovation ensure that we can meet the most demanding requirements of modern industrial applications. To learn more about our sintered bearing products or to discuss your specific needs, please contact us at info@wingold.cc. Our team of experts is ready to help you find the perfect bearing solution for your high-temperature applications.

FAQs

What temperature range can sintered bearings withstand?

Sintered bearings can typically operate in temperatures ranging from -40°C to 150°C, depending on the specific material and sintered bearing oil used.

How long do sintered bearings last in high-temperature applications?

The lifespan of sintered bearings in high-temperature applications can vary depending on the specific conditions, but they generally offer extended service life compared to conventional bearings, often lasting several years without requiring replacement.

Can sintered bearings be used in corrosive high-temperature environments?

Yes, certain sintered bearing materials are designed to resist corrosion, making them suitable for use in corrosive high-temperature environments commonly found in chemical and petrochemical industries.