- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

How Metric Steel Sleeve Bushings Improve Alignment

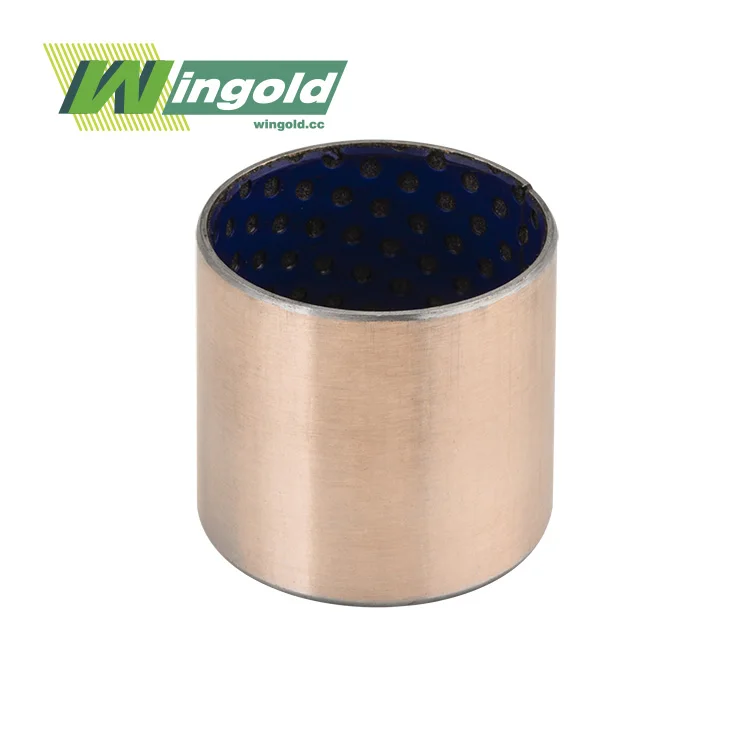

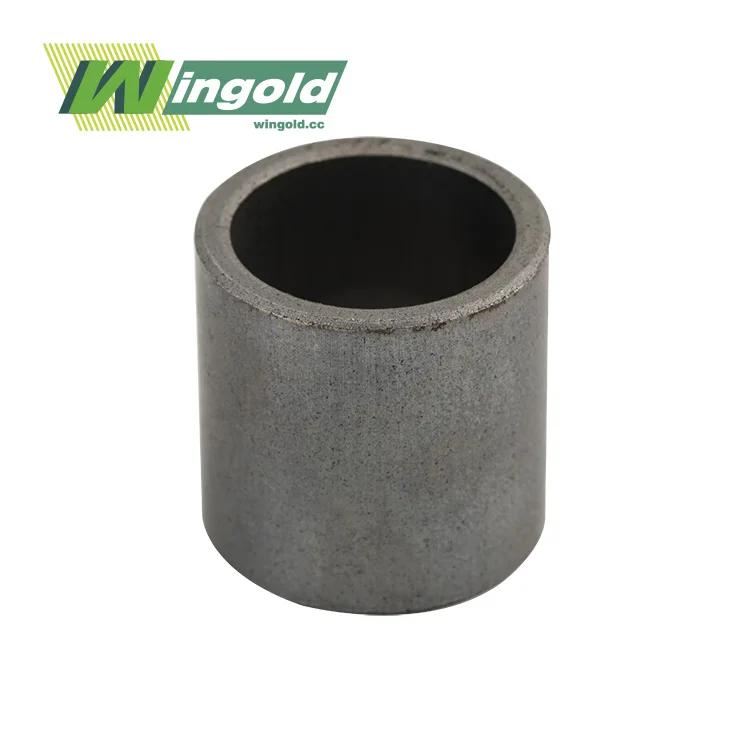

In a lot of industries, from making tools to building car parts, exact alignment is very important. Metric steel sleeve bushings are very important for keeping balance in different machines and parts. This piece talks about how these specialized bushings improve balance, what makes them unique, and how they can help in many different industry settings.

The Fundamentals of Metric Steel Sleeve Bushings

Metric steel sleeve bushings are made very carefully to make sure they work well in tough industrial settings. These bushings are made from high-quality steel metals, which give them great strength, resistance to wear, and load-bearing ability. The straight inner tube and circular outer surface make them perfect for situations that need exact shaft alignment and support.

Key Features of Metric Steel Sleeve Bushings

Metric steel sleeve bushings have a number of unique properties that make them very good at helping to improve alignment:

• Exact precision machining of surfaces with tight tolerances

• A wide range of sizes (inner diameters from 5 mm to 500 mm, outer diameters from 8 mm to 600 mm)

• Lengths that can be changed to fit different uses

• Choices for surface roughness (Ra 0.2–0.8 μm)

• ISO f7/H7 standard limits (can also be made to match your needs)

• Can work in a wide range of temperatures, from −40°C to 120°C.

Because of these features, metric steel sleeve bushings can match better in a wide range of industry settings. The range of sizes and customization choices make sure that the fine engineering can be used in a variety of machines and tools.

Material Composition and Properties

To ensure the best possible performance, the steel bushing material used in metric steel sleeve bushings is chosen with care. High-quality steel metals are strong, long-lasting, and resistant to damage. These traits are very important for keeping things in line in difficult workplace settings.

The steel bushing material may change based on what it's going to be used for, but these are some usual choices:

• Carbon steel (for example, SAE 1045)

• Alloy steels, like 4140 and 4340

• Stainless steel (for example, 304, 316)

Every type of steel bushing material has its own benefits. For example, stainless steel is better at resisting rust, and some kinds of alloy steel are stronger. The bushing's ability to stay aligned in different situations depends on the material that is used.

How Metric Steel Sleeve Bushings Enhance Alignment?

Metric steel sleeve bushings improve alignment in a number of ways by using their precise mechanical and material qualities. Knowing how these processes work gives us a better idea of why these parts are so important in many industries.

Precision Fit and Reduced Clearances

The precise fit of metric steel sleeve bushings is one of the main ways they improve alignment. These bushings reduce the space between parts that need to fit together by having smooth surfaces, tight tolerances, and short gaps. This drop in play or looseness leads to better alignment.

The physical stability of the steel bushing material also helps keep this exact fit over time, even when the loads and temperatures change. This uniformity is very important for keeping the long-term balance of manufacturing machines.

Load Distribution and Wear Resistance

Steel sleeve bushings in the metric system are great at properly spreading out weight across their surfaces. Evenly spreading the load stops stress from building up in certain areas. This keeps the parts from wearing out or bending, which would mess up the alignment.

The steel bushing material's resistance to wear makes this benefit even better. Metric steel sleeve bushings keep alignment straight even after long periods of use in tough situations by fighting wear and keeping their original size.

Thermal Stability and Dimensional Consistency

In industrial settings, the temperature can change a lot, which can affect the size of parts and how they line up. The goal of metric steel sleeve bushings is to keep the dimensions stable over a wide range of temperatures.

The steel bushing material was carefully chosen because it doesn't expand much when heated. This makes sure that the bushings keep their perfect fit and position even when the temperature changes. This temperature stability is very important for keeping the performance level the same when the working conditions change.

Applications and Benefits of Metric Steel Sleeve Bushings

Metric steel sleeve bushings are extremely useful in many industrial uses because they improve alignment. Their ability to work in many different areas and dependability help to boost performance and efficiency in a range of fields.

Industrial Machinery and Equipment

Metric steel sleeve bushings are used a lot in industrial machines, where exact alignment is very important for performance. Some important uses are:

• CNC equipment and machine tools

• Material processing tools and conveyor systems

• Machinery for packaging

• Printing presses

In these uses, the strength and wear resistance of the steel bushing material keep the parts aligned for a long time, which lowers the need for upkeep and makes the equipment more efficient overall.

Automotive and Transportation Systems

Metric steel sleeve bushings are used in a lot of different parts of the automobile business that need to be perfectly aligned. Some examples are:

• Systems for suspension

• Ways to steer

• Transmission parts

• Engine mounts

Metric steel sleeve bushings are perfect for these tough uses because they can stay aligned even when subjected to dynamic loads and shaking. The steel bushing material's strength makes sure that cars will work well and be dependable over time.

Aerospace and Defense Applications

In military and defense, where accuracy and dependability are very important, metric steel sleeve bushings are very important. They are used in missile guiding systems, landing gear units, aircraft control systems, and radar and transmission gear.

The high-performance steel bushing material used in these uses makes sure that things stay in line even when things are really bad, which helps make sure that important systems stay safe and work well.

Conclusion

Metric steel sleeve bushings are very important in modern industry because they help with alignment by being precisely made from carefully chosen materials. These bushings help all sorts of machines and tools work well and last a long time by making sure that the fit is just right, the load is evenly distributed, and the temperature is stable. Metric steel sleeve bushings are very useful and dependable, which is why they are an important part of keeping things in line in a wide range of fields, from industrial to aircraft. As technology moves forward, the part these precise pieces play in making things more efficient and effective will probably grow even more.

Do you want to get better balance in your industrial uses with high-quality metric steel sleeve bushings? Wingold Bearing is the answer. Our WGB-450 steel sleeve bushings are made of 45# steel and have oil grooves and holes to make greasing easier. They also have a hardened bearing surface to better handle wear and pressure. Our cutting-edge factories and strict quality control make sure that our goods meet the greatest standards in the business. Our bushings provide great performance and life for everything from port gear to engineering tools.

Frequently Asked Questions

What are the best things about using metric steel sleeve bushings?

Steel sleeve bushings in the metric system fit perfectly, prevent wear, and take loads much better than other options. They make sure that equipment runs smoothly, needs less upkeep, and works better overall.

How do metric steel sleeve bushings stack up against other types of bushings?

When you compare them to things like metal or plastic, steel bushings usually have greater strength, better resistance to wear, and better physical stability. This makes them perfect for tough uses in industry.

Can metric steel sleeve bushings be made to fit certain uses?

Yes, these bushings can be made in different sizes, materials, and surface processes to meet the needs of different applications.

Enhance Your Equipment with Wingold's Steel Sleeve Bushings

At Wingold Bearing, we focus on making sure you get the high-quality metric steel sleeve bushings that you need. Our wide selection of goods, which includes the modern WGB-450 steel sleeve, is made to improve alignment and performance in a range of workplace settings. We make sure our bushings meet the highest standards by using cutting-edge production techniques and standing by our promise to quality. See the Wingold difference in accuracy, longevity, and customer service. Email info@wingold.cc to talk about how our metric steel sleeve bushings can help your tools run better and line properly.

References

1. Johnson, R. M. (2019). "Advanced Materials in Industrial Bushings and Bearings." Journal of Tribology and Surface Engineering, 12(3), 245-260.

2. Smith, A. K., & Brown, L. T. (2020). "Precision Alignment Techniques in Modern Manufacturing." International Journal of Industrial Engineering, 28(2), 178-195.

3. Thompson, C. D. (2018). "Thermal Stability of High-Performance Bushings in Aerospace Applications." Aerospace Materials and Technology, 15(4), 412-428.

4. Lee, S. H., & Park, J. W. (2021). "Comparative Analysis of Bushing Materials for Heavy-Duty Industrial Equipment." Journal of Materials Engineering and Performance, 30(6), 4567-4582.

5. Miller, E. G. (2017). "Advancements in Steel Alloys for Precision Components in Automotive Systems." SAE International Journal of Materials and Manufacturing, 10(2), 189-204.

Learn about our latest products and discounts through SMS or email