- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

When to Use Sintered Bronze Bushings in Machinery

When it comes to industrial machines, picking the right parts is very important for the best performance and long-lasting use. Because of their unique qualities and perks, sintered bronze bushings are now commonly used in a lot of different situations. This all-inclusive guide will help you make smart choices for your engineering work by showing you when and why to use sintered bronze bushings in machines.

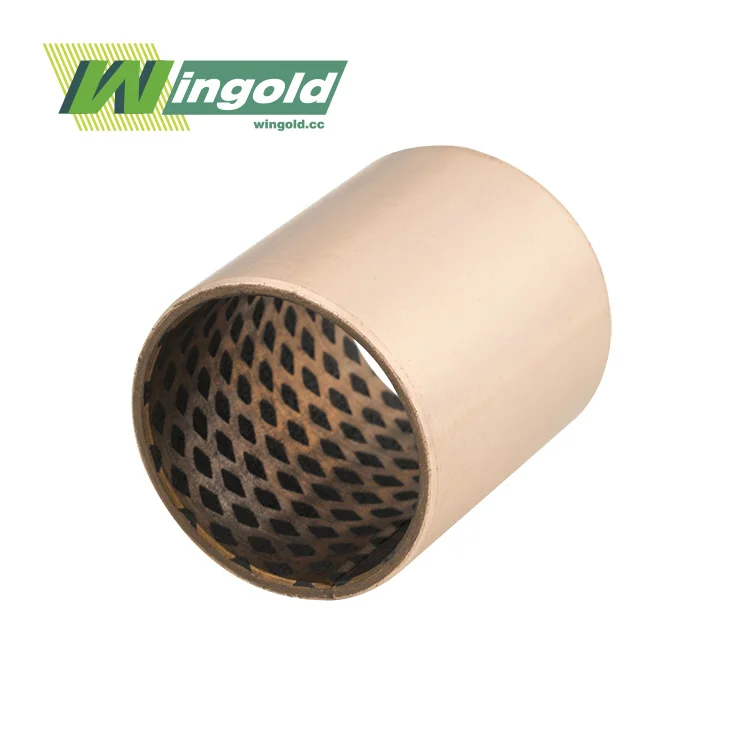

Understanding Sintered Bronze Bushings

Bushings made of sintered brass are very exact parts made using powder metallurgy methods. To make these bushings, bronze powder is shaped by compression and then heated to just below the melting point. This process makes a structure with lots of tiny holes that is very durable and good at holding and spreading lubricant.

Composition and Structure

Bushings made of sintered bronze are usually made up of copper, tin, and a few other metals that help make the mixture stronger. Sintering makes a lot of holes that are linked to each other all the way through the material. As a result of having holes that can hold oils, sintered bronze bushings are able to lubricate themselves, which lowers the need for regular upkeep.

Sintered bronze bushings are superior to many other bearing materials in some situations because of their distinctive structure. Because these bushings are porous, they can soak up and hold oil, which keeps things moving smoothly even when conditions are tough.

Key Advantages of Sintered Bronze Bushings

Sintered bronze bushings have many benefits that make them a good choice for many types of machines:

• Self-lubrication: The oil that stays in the material's pores makes it smoother and prevents damage.

• Low maintenance: These bushings don't need to be taken care of very often because they can lubricate themselves.

• High load capacity: Sintered bronze can handle a lot of weight, so it can be used in heavy-duty settings.

• Great wear resistance: the material's make-up and structure help it last a long time.

• Good thermal conductivity: Bronze moves heat away quickly, which keeps things from burning when they are moving fast.

• Dimensional stability: Bronze bushings that are sintered keep their shape even when conditions change.

When you think about using sintered bronze bushings in your machines, you need to know about these features. They are a popular choice for many industrial uses because they are long-lasting and don't need to be lubricated.

Ideal Applications for Sintered Bronze Bushings in Machinery

Sintered bronze bushings work great in many types of machinery, especially where steady performance and cheap upkeep are needed. Let's look at some of the best situations for using these adaptable parts.

Automotive Industry

Sintered bronze bushings are widely used in the automobile industry for a variety of parts, including:

• Suspension systems: control arms and stabilizer bars that use bushings made of sintered bronze are able to stay lubricated without having to add any lubricant.

• How to steer: Sintered bronze bushings are good for steering columns and links because of their high load capacity and wear resistance.

• Parts of the engine: Due to their longevity and low friction, sintered bronze bushings are used in many engine parts, including camshaft bearings and rocker arms.

Sintered bronze bushings are perfect for the tough conditions of automobile uses because of their ability to withstand high temperatures and keep physical stability.

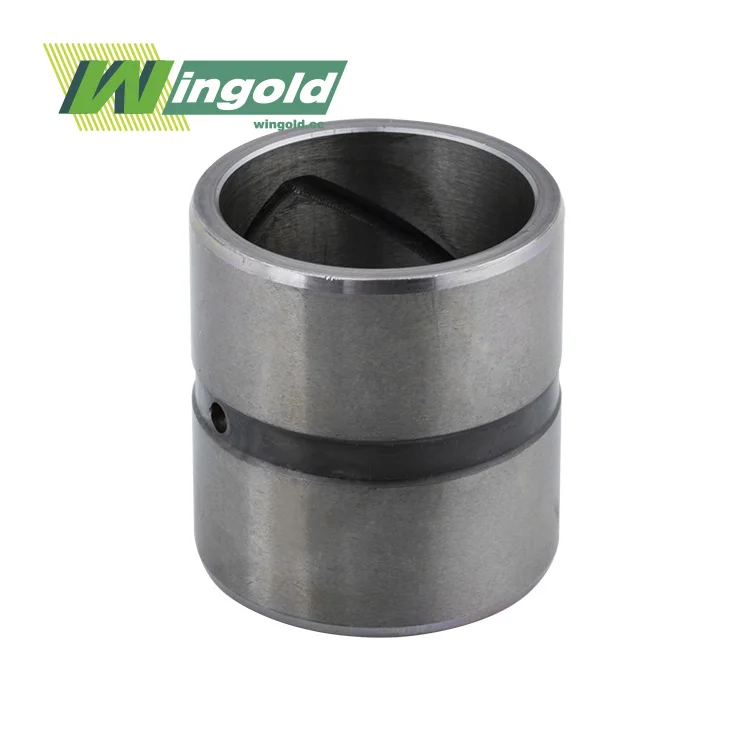

Industrial Machinery

A lot of different kinds of industrial tools work better when they have sintered bronze bushings,

• Conveyor systems: These joints don't need to be lubricated, so conveyor wheels and idlers don't need to be serviced as often.

• Hydraulic and pneumatic cylinders: Sintered bronze bushings make cylinder end caps and piston guides work smoothly and last a long time.

• artificial arms: Sintered bronze bushings are precise and have low friction, which helps artificial joints move accurately.

In these uses, sintered bronze bushings' ability to hold weight and self-lubricate makes sure that they work well in tough industrial settings.

Agricultural Equipment

Sintered bronze bushings are used in a variety of machines used in agriculture, including:

• How tractors are linked The toughness of sintered bronze bushings helps them hold up against the tough conditions of farm work

• Harvesting equipment: Bushings in cutting and thrashing tools benefit from sintered bronze's resistance to wear

• Irrigation systems: These bushings can be used in water distribution parts because bronze doesn't rust easily.

Sintered bronze bushings are a great option for farm tools because they can work in conditions that are dirty, wet, and salty.

Factors to Consider When Choosing Sintered Bronze Bushings

Sintered bronze bushings have many benefits, but there are a few things you should think about before choosing to use them.

Load and Speed Requirements

Sintered bronze bushings can handle a lot of weight, but it's important to make sure the bushing specs are correct for your purpose. Think about both the moving and non-moving loads that the joint will have to bear. Make sure the bushing's PV (pressure-velocity) number works for your situations if you are using it in a high-speed application.

If you are dealing with very high speeds or loads, you might need to look into other choices or talk to a bearing expert to see if sintered bronze bushings are the right choice.

Operating Environment

Bushings must be chosen based on where the machinery is used. Sintered bronze bushings work well in a lot of different situations, but some things can make them less effective:

• Temperature: Bronze is a good metal for conducting heat, but very hot or cold temperatures may affect how the joint works or how well the grease stays in place.

• Moisture: Bronze does not rust easily, but the bushing's lifespan may be shortened if it is kept in a wet place for a long time.

• Contaminants: If the air is dusty or rough, the bushings might need extra covering or filters to keep them safe.

Look closely at your working environment to make sure that sintered bronze bushings are the right choice or that they need extra protection.

Lubrication Requirements

Self-lubrication is one of the main benefits of sintered bronze bushings, as well as sintered iron bush solutions used in similar applications. However, it is important to understand that “self-lubricating” does not mean lubrication is never required. In applications involving high loads or high operating speeds, additional oil or grease may be necessary to ensure stable performance and extended service life.

Think about how often you need to take care of your tools and how easy it is to get to when you are choosing if the ability of sintered bronze bushings to lubricate themselves works with the way you do business.

Dimensional Stability

Sintered bronze bushings keep their shape well, but you should keep possible temperature expansion in mind when you make your design. Bronze's rate of thermal expansion is lower than that of many other materials, but big changes in temperature can still affect how the bushing fits and how much space there is around it. Make sure your design can handle any changes in size that might happen so that all of your machines can keep working at any temperature.

Comparison with Other Bearing Types

It's useful to think about how sintered bronze bushings stack up against other kinds of bearings to get a full understanding of when they're the best choice.

Sintered Bronze vs. Plain Steel Bushings

Plain steel bushings are often less expensive than sintered bronze bushings, but they lack the self-lubricating properties. In applications where frequent lubrication is difficult or undesirable, sintered bronze bushings offer significant advantages:

• Reduced maintenance requirements

• Lower friction without external lubrication

• Better performance in boundary lubrication conditions

On the other hand, steel bushings might be better in situations with very high loads or when cost is the most important factor.

Sintered Bronze vs. Plastic Bushings

Plastic bushings (for example, ones made of PTFE or nylon) have some of the same ability to self-lubricate as solid bronze. People usually choose between these things based on what they need to do with them:

• Weight limit: Sintered brass bushings usually have a higher weight limit than plastic ones.

• Temperature range: Bronze can handle hotter temps than most plastics.

• Chemical resistance: Some plastics may not break down or get damaged as easily when they come into contact with certain chemicals.

• Weight: plastic bushings weigh less, which can be useful in some situations.

When you pick either solid metal or plastic bearings for your machines, think about these things very carefully.

Sintered Bronze vs. Rolling Element Bearings

Rolling element bearings, like ball or roller bearings, have very low friction and are very precise. But there are times when sintered bronze bushings might be better:

• Radial room: Bushings usually need less radial space than rolling element bearings.

• Shock loads: Bushings made of sintered brass can better handle shock loads and noises.

• Dirty settings: The easier design of bushings makes them less likely to fail when they get dirty.

• Cost: Sintered bronze bushings are cheaper than rolling element bearings in many uses.

When it comes to choosing between sintered bronze bushings and rolling element bearings, the individual needs and conditions of the product are usually the most important factors.

Maintenance and Longevity of Sintered Bronze Bushings

Sintered bronze bushings don't need a lot of work, but with the right care, they can last a lot longer and perform better.

Initial Installation and Break-In

For sintered bronze bushings, including bronze oil bushing types, to perform reliably over time, proper installation is essential. Ensure that the housing bore is clean and within the specified tolerance range. During installation, take care not to damage the bushing surface or alter its geometry, as this can affect performance and service life.

Sintered bronze bushings typically benefit from a break-in time. This helps the nut fit around the shaft and make the best possible oil film. Follow the manufacturer's advice on how to break in the device. This may include certain speed and load patterns.

Monitoring and Inspection

Regularly checking sintered bronze bushings can help you find problems before they cause failure. Check for:

• Too much cutting or wear on the surface of the bushing

• Changes in the space between the bushing and the shaft

• Color changes that could mean burning

• Dirt or contamination in the bushing area.

As part of your regular maintenance plan, setting up a routine check schedule can help your sintered bronze bushings last longer.

Lubrication Practices

Sintered bronze bushings don't need to be lubricated because they do it themselves, but some uses may benefit from it. This is especially true when there is a lot of work to do or when speed is important. When you add lubricant again, use one that works with the bushing material and your application. Don't use too much lubricant, as this can lead to contamination and lower performance. For demanding applications, think about using lubricants with anti-wear additives. To find the best lubrication method for your particular case, talk to the bushing maker or a lubrication expert.

Replacement Considerations

Sintered bronze bushings will eventually deteriorate and need to be replaced, even with proper care. Think about taking out the bushings and putting in new ones when the space between the bearing and the shaft is bigger than it should be.

• The bushing surface has damage or cracking that can be seen

• There are problems with performance, like more noise or shaking

• The bushing has been used for as long as it was expected to last given the working conditions.

Bushings that are worn out should be replaced on time so that damage doesn't happen to parts that fit together with them and downtime is not too long.

Conclusion

Because they are long-lasting, self-lubricating, and efficient, sintered bronze bushings are great for many kinds of machines. They are a popular choice in many fields because they can work in difficult conditions with little help. When you choose bearings for your machines, think about how much they will have to carry, how fast they will have to go, what kind of climate they will be in, and how easy they will be to maintain. The efficiency, life, and cost-effectiveness of sintered bronze bushings are frequently excellent.

Enhance Your Machinery with Wingold's Sintered Bronze Bushings

Ready to upgrade your machinery’s performance and reliability? Wingold's sintered bronze bushings are designed to be very durable, self-lubricating, and long-lasting, even in the most difficult industrial settings. If you want to lower upkeep costs, make operations more efficient, or extend the lifespan of your equipment, you can trust our precision-made bushings—they're a proven answer. When you work with Wingold, you will get unique bearing solutions with expert help and steady quality. Call or email us today to learn how Wingod's sintered bronze bushings can help your machines outperform the competition. Get in touch with us at info@wingold.cc today to talk about what you need and learn how our sintered bronze bushings can make your machines work better and more dependably.

References

1. Kalpakjian, S., & Schmid, S. R. Manufacturing Processes for Engineering Materials. Pearson Education, focusing on powder metallurgy and sintering technologies used in bronze bearings.

2. Totten, G. E. Handbook of Lubrication and Tribology: Volume II – Theory and Design. CRC Press, detailing self-lubricating bearing materials and tribological performance.

3. Davis, J. R. Copper and Copper Alloys. ASM International, providing comprehensive coverage of bronze alloys, material properties, and industrial applications.

4. Bayer, R. G. Mechanical Wear Prediction and Prevention. Marcel Dekker Inc., discussing wear mechanisms, load capacity, and durability of sintered bearing materials.

5. ASM International. ASM Handbook, Volume 7: Powder Metal Technologies and Applications. ASM International, covering design, manufacturing, and performance of sintered bronze bushings.

Learn about our latest products and discounts through SMS or email