Understanding High Temperature Sleeve Bearings

Composition and Properties of High Temperature Sleeve Bearings

High temperature sleeve bearings are engineered to withstand extreme thermal conditions while maintaining optimal performance. These bearings are typically crafted from advanced materials such as self-lubricating graphite composites, high-performance polymers like PEEK (Polyether Ether Ketone), PPS (Polyphenylene Sulfide), and PAI (Polyamide-imide), ceramic-metal alloys, or specialized metal alloys based on nickel or cobalt.

The unique composition of high temperature sleeve bearings endows them with exceptional properties. They boast remarkable thermal stability, allowing them to maintain their structural integrity and performance characteristics even when subjected to temperatures as high as 800°C (1472°F). This thermal resilience is coupled with an impressively low coefficient of friction, typically ranging from 0.02 to 0.08, which significantly reduces wear and extends the bearing's operational life.

Moreover, these bearings exhibit superior load-bearing capacity, capable of withstanding pressures up to 140 MPa. This makes them ideal for applications involving heavy machinery or high-stress environments. Their ability to operate at shaft speeds of up to 2 m/s further enhances their versatility across various industrial applications.

Applications of High Temperature Sleeve Bearings

The exceptional properties of high temperature sleeve bearings, often designed as oil groove bushings, make them indispensable in numerous industries and applications where standard bearings would fail. In the aerospace sector, these bearings are crucial components in jet engines, where they must withstand extreme temperatures and high-speed rotations. The automotive industry relies on them for turbochargers and exhaust gas recirculation systems, where heat resistance is paramount.

In the industrial realm, high temperature sleeve bearings find applications in furnace conveyor systems, kiln car wheels, and steel mill equipment. They are also vital in chemical processing plants, where they encounter corrosive substances and high temperatures. The power generation sector employs these bearings in steam turbines and generators, leveraging their ability to maintain performance under intense heat and pressure.

Additionally, these bearings play a crucial role in glass manufacturing processes, continuous casting in metallurgy, and even in advanced robotics designed for extreme environments. Their versatility and resilience make high temperature sleeve bearings an essential component in pushing the boundaries of what's possible in high-heat industrial applications.

Advantages of High Temperature Bronze Bearings

Thermal Stability and Performance

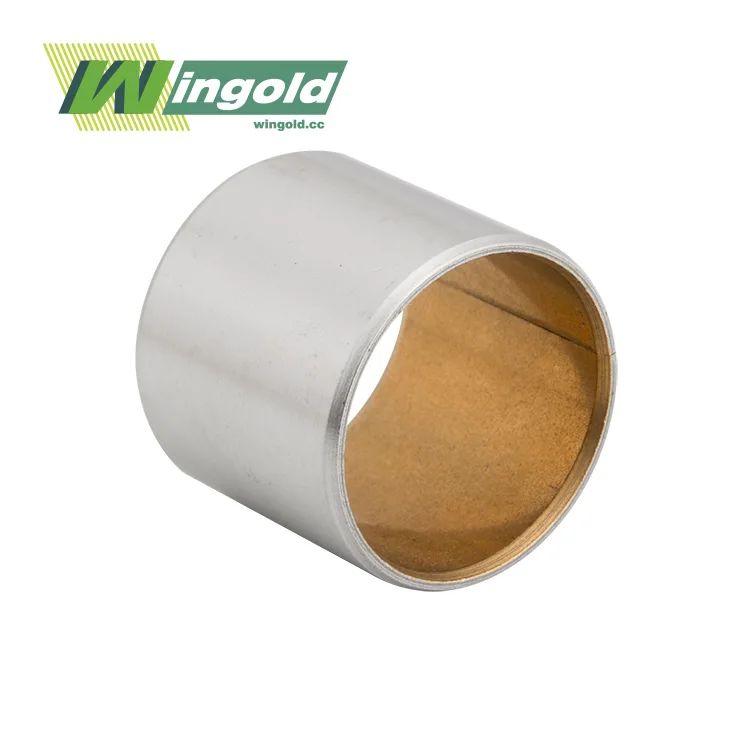

High temperature bronze bearings, exemplified by products like Wingold's WGB-090, demonstrate remarkable thermal stability. These bearings utilize specially formulated high-density copper alloy strips as their base, allowing them to maintain structural integrity and performance characteristics even under extreme heat. This thermal resilience enables them to operate efficiently in environments where temperatures can soar up to 800°C (1472°F), far surpassing the capabilities of standard sleeve bearings.

The thermal stability of these bronze bearings translates directly into enhanced performance. They exhibit minimal thermal expansion, ensuring consistent clearances and alignment even as temperatures fluctuate. This stability prevents seizure or binding, common issues with less heat-resistant bearings, thereby ensuring smooth and uninterrupted operation of machinery in high-temperature scenarios.

Load Capacity and Wear Resistance

One of the standout features of high temperature bronze bearings, including oil bronze bearings, and high temperature sleeve bearings is their exceptional load-bearing capacity. The high-density copper alloy composition provides these bearings with the strength to withstand pressures up to 140 MPa.This robust load capacity makes them ideal for applications involving heavy machinery or high-stress environments, where standard bearings might buckle under the pressure.

Coupled with their high load capacity is superior wear resistance. The surface of these bearings can be engineered with diamond or hemispherical oil holes and oil grooves, enhancing their self-lubricating properties. This design significantly reduces friction, minimizing wear even under heavy loads and high temperatures. The result is a bearing that not only performs better but also lasts longer, reducing the frequency of replacements and associated downtime.

Customization and Versatility

High temperature bronze bearings offer a high degree of customization, allowing them to be tailored to specific application requirements. They can be manufactured in various forms including bearings, flanged sleeves, thrust washers, and ball bowls. This versatility makes them suitable for a wide range of industries and applications, from lifting and construction machinery to automobile tractor chassis and mining equipment.

The ability to customize these bearings extends to their size and shape. With inner diameters ranging from 10mm to 500mm, outer diameters from 14mm to 560mm, and lengths from 10mm to 1000mm, these bearings can be precision-crafted to fit virtually any application. This flexibility, combined with their superior performance characteristics, makes high temperature bronze bearings a versatile solution for challenging industrial environments.

Comparing Standard Sleeve Bearings to High Temperature Alternatives

Material Differences and Heat Resistance

Standard sleeve bearings are typically made from materials such as plain steel, bronze, or polymer composites. While these materials perform adequately in normal conditions, they fall short in high-temperature environments. Their heat resistance is generally limited to temperatures below 200°C, beyond which they may experience rapid degradation, loss of structural integrity, and failure.

In contrast, high temperature sleeve bearings, particularly those made from specialized bronze alloys or advanced composites, can withstand temperatures up to 800°C. This vast difference in heat resistance is due to the unique composition and manufacturing processes of high temperature bearings. The specially formulated alloys and advanced materials used in their construction maintain their properties even under extreme heat, ensuring consistent performance where standard bearings would fail.

Maintenance Requirements and Longevity

Standard sleeve bearings often require regular maintenance and lubrication to ensure optimal performance. In high-temperature environments, this maintenance becomes more frequent and challenging, as traditional lubricants may break down or evaporate quickly. The need for constant re-lubrication not only increases maintenance costs but also poses operational challenges in hard-to-reach or continuous operation machinery.

High temperature sleeve bearings, particularly those with self-lubricating properties like the WGB-090 bronze bearings, significantly reduce maintenance requirements. Their ability to operate without external lubrication in extreme temperatures translates to less downtime, lower maintenance costs, and increased overall efficiency. The longevity of these bearings in high-temperature applications far exceeds that of standard sleeve bearings, making them a more cost-effective solution in the long run despite higher initial costs.

Cost Considerations and ROI

At first glance, standard sleeve bearings may appear more economical due to their lower upfront costs. However, when considering applications in high-temperature environments, the total cost of ownership paints a different picture. The frequent replacements, increased maintenance, and potential for catastrophic failure associated with standard bearings in extreme conditions can lead to significant long-term expenses and production losses.

High temperature sleeve bearings, while more expensive initially, offer a superior return on investment in demanding applications. Their extended lifespan, reduced maintenance needs, and ability to operate reliably in extreme conditions result in lower overall costs over time. For industries where downtime is exceptionally costly or where bearing failure could lead to safety hazards, the investment in high temperature bearings is not just economical but often necessary.

Conclusion

In conclusion, while standard sleeve bearings have their place in many applications, high temperature bronze bearings offer unparalleled performance in extreme conditions. Their superior thermal stability, load capacity, and wear resistance make them the ideal choice for industries facing high-temperature challenges. As a leading high temperature sleeve bearing manufacturer and supplier, Wingold Bearing is committed to providing innovative solutions that drive industrial efficiency and reliability.

For those seeking to optimize their high-temperature operations or explore custom bearing solutions, we invite you to reach out to our team of experts. Contact us at info@wingold.cc to discuss how our high temperature sleeve bearings can elevate your industrial processes and overcome your toughest engineering challenges.

Frequently Asked Questions

What is the maximum temperature a high temperature sleeve bearing can withstand?

High temperature sleeve bearings can withstand temperatures up to 800°C (1472°F), depending on the specific material and design.

How do high temperature bronze bearings compare to ceramic bearings?

While ceramic bearings offer excellent heat resistance, bronze bearings often provide better load capacity and are more cost-effective for many industrial applications.

Can high temperature sleeve bearings be used in corrosive environments?

Yes, many high temperature sleeve bearings are designed to resist corrosion, making them suitable for use in chemically aggressive environments.

What industries benefit most from high temperature sleeve bearings?

Industries such as aerospace, automotive, metallurgy, and chemical processing benefit greatly from high temperature sleeve bearings due to their extreme operating conditions.