Understanding Bronze Thrust Bearings and Their Importance

Bronze thrust bearings play a pivotal role in numerous industrial applications, offering exceptional performance in high-load, low-speed scenarios. These bearings are crafted from high-quality copper alloys, typically consisting of copper, tin, and other elements, which contribute to their remarkable properties. The unique composition of bronze thrust bearings integrates the strength of bronze with self-lubricating traits, ensuring seamless operation and extended service life.

The importance of bronze thrust bearings in industrial machinery cannot be overstated. They excel in handling axial loads, which are forces applied parallel to the shaft's axis. This capability makes them indispensable in various applications, including:

- Hydraulic and pneumatic systems

- Forging and pressing machine tools

- Lifting and handling machinery

- Port machinery

- Textile machinery

- Automotive industry

- Railway locomotives

- Shipbuilding industry

The superior properties of bronze thrust bearings include:

- Excellent load-bearing capacity

- Superior wear resistance

- Low friction coefficients

- Good thermal conductivity

- Corrosion resistance

These characteristics contribute to the reliability and durability of bronze thrust bearings, making them a preferred choice in demanding industrial environments. Understanding the significance of these bearings is crucial for recognizing when replacement is necessary to maintain optimal equipment performance.

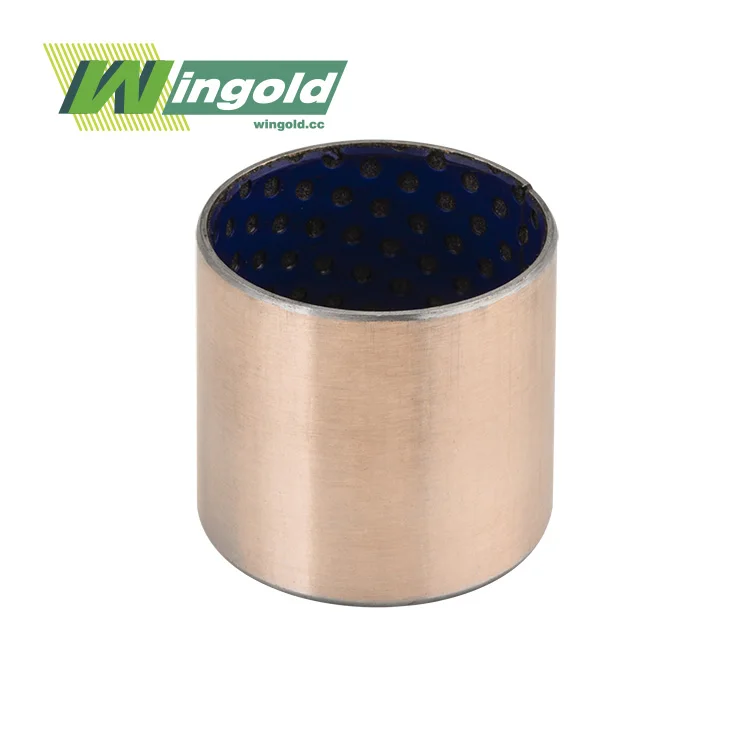

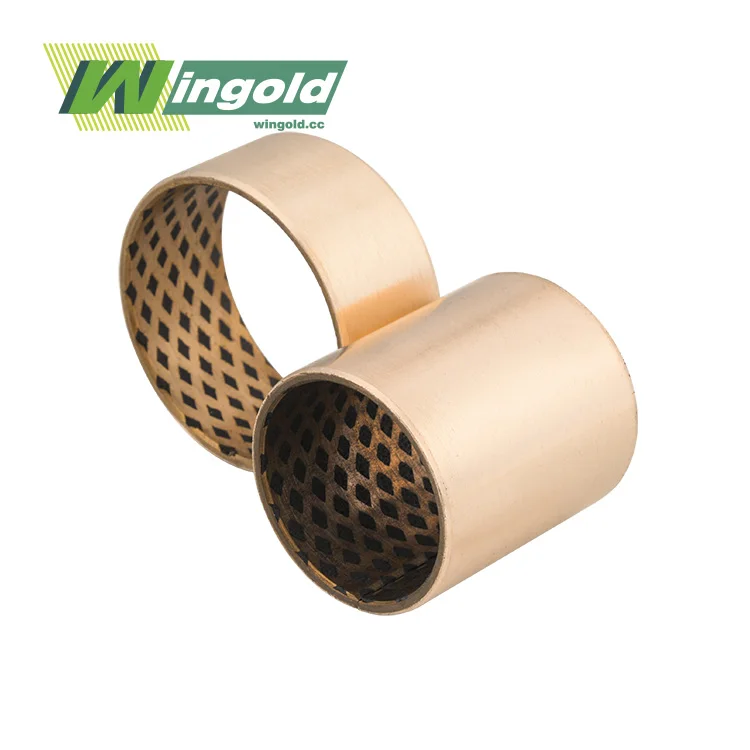

The Structure and Function of Bronze Thrust Bearings

Bronze thrust bearings consist of two main components: the bearing ring and the thrust collar. The bearing ring is typically made of bronze, while the thrust collar is often made of hardened steel. This combination of materials allows for optimal performance under high axial loads.

The surface of bronze thrust bearings can be engineered with specific features to enhance their performance. For instance, the WGB-090 bronze bearings use specially formulated high-density copper alloy strips as the base. The surface can be rolled with diamond or hemispherical oil holes and oil grooves according to user requirements. These features contribute to the bearing's high density, large load-bearing capacity, good wear resistance, and long service life.

The primary function of bronze thrust bearings is to support axial loads while allowing rotational movement. They achieve this by distributing the load over a larger surface area, reducing friction and wear. The self-lubricating properties of bronze further enhance this function by creating a thin film of lubricant between the bearing surfaces, minimizing metal-to-metal contact.

Key Signs That Indicate the Need for Bronze Thrust Bearing Replacement

Identifying the signs that your bronze thrust bearing needs replacement is crucial for maintaining the efficiency and longevity of your machinery. Here are the key indicators to watch out for:

Unusual Noise or Vibration

One of the most noticeable signs of a failing bronze thrust bearing is unusual noise or vibration. As the bearing wears, it may produce grinding, squealing, or rumbling sounds. Increased vibration can also be felt in the machinery, indicating that the bearing is no longer functioning smoothly. These auditory and tactile cues should not be ignored, as they often signify significant wear or damage to the bearing.

Increased Operating Temperature

Bronze thrust bearings are designed to operate within specific temperature ranges. If you notice an unusual increase in operating temperature around the bearing area, it could indicate excessive friction due to wear or inadequate lubrication. Regular temperature monitoring can help detect this issue early, preventing potential damage to both the bearing and the machinery.

Visible Wear or Damage

Physical inspection of the bronze thrust bush bearing can reveal visible signs of wear or damage. Look for scoring, pitting, or discoloration on the bearing surface. Cracks, chips, or deformation in the bearing structure are serious indicators that replacement is necessary. Regular visual inspections should be part of your maintenance routine to catch these issues early.

Reduced Efficiency or Performance

A decline in machinery performance or efficiency can often be traced back to worn bronze thrust bearings. If you notice increased power consumption, reduced output, or difficulty in maintaining proper alignment, it may be time to inspect and potentially replace the bearings. These performance issues can lead to increased operational costs and reduced productivity if not addressed promptly.

Contamination or Lubrication Issues

Bronze thrust bearings rely on proper lubrication to function effectively. Signs of contamination, such as debris in the lubricant or discoloration, can indicate that the bearing's performance is compromised. Similarly, if you notice leaking or inadequate lubrication, it can lead to increased friction and wear, necessitating bearing replacement.

Preventive Measures and Maintenance for Bronze Thrust Bearings

Implementing a robust preventive maintenance program can significantly extend the life of your bronze thrust bearings and help you avoid unexpected failures. Here are some key strategies to incorporate:

Regular Inspection and Monitoring

Establish a routine inspection schedule for your bronze thrust bearings. This should include visual checks for wear, damage, or contamination. Implement condition monitoring techniques such as vibration analysis and temperature monitoring to detect early signs of bearing deterioration. Regular inspections allow you to identify potential issues before they escalate into major problems.

Proper Lubrication Practices

Adequate lubrication is crucial for the optimal performance of bronze thrust bearings. Ensure that you're using the correct type and amount of lubricant for your specific bearing and application. Develop a lubrication schedule based on the manufacturer's recommendations and your operating conditions. Regularly check for signs of contamination or degradation in the lubricant and replace it as needed.

Alignment and Load Management

Proper alignment of machinery components is essential for the longevity of bronze thrust bearings. Misalignment can lead to uneven load distribution and premature wear. Regularly check and adjust the alignment of your equipment. Additionally, ensure that the loads applied to the bearings are within their designed capacity. Overloading can cause rapid deterioration and failure.

Environmental Control

The environment in which bronze thrust bearings operate can significantly impact their performance and lifespan. Control factors such as temperature, humidity, and exposure to contaminants. Implement appropriate sealing and filtration systems to protect the bearings from dust, moisture, and other harmful elements. Maintaining a clean and controlled environment can substantially extend the life of your bearings.

Staff Training and Education

Invest in training your maintenance staff on proper handling, installation, and care of bronze thrust bearings. Ensure they understand the importance of these components and can recognize early signs of wear or damage. Well-trained personnel can significantly contribute to the longevity and reliability of your bearings.

Conclusion

Understanding the signs that indicate the need for bronze thrust bearing replacement is crucial for maintaining the efficiency and reliability of your industrial machinery. By paying attention to unusual noises, increased temperatures, visible wear, performance issues, and contamination, you can prevent unexpected breakdowns and costly downtime. Implementing a comprehensive preventive maintenance program, including regular inspections, proper lubrication, alignment checks, and environmental control, will help extend the life of your bronze thrust bearings and optimize your equipment's performance.

When it's time to replace your bronze thrust bearings, choosing a reliable supplier is essential. As a leading bronze thrust bearing manufacturer and supplier, Jiashan Wingold Bearing Co., Ltd. offers high-quality, customized solutions to meet your specific needs. With over 20 years of industry experience, rigorous quality control processes, and comprehensive technical support, we ensure that you receive the best products for your applications. For more information about our bronze thrust bearings or to discuss your requirements, please contact us at info@wingold.cc.

Frequently Asked Questions

How often should bronze thrust bearings be replaced?

The replacement frequency depends on various factors such as operating conditions, load, and maintenance practices. Generally, it's recommended to inspect bearings regularly and replace them when signs of wear or performance issues are detected.

Can bronze thrust bearings be repaired instead of replaced?

In most cases, it's more cost-effective and reliable to replace worn bronze thrust bearings rather than attempt repairs. However, minor surface irregularities might be addressed through reconditioning in some instances.

What are the advantages of bronze thrust bearings over other materials?

Bronze thrust bearings offer excellent load-bearing capacity, superior wear resistance, low friction coefficients, good thermal conductivity, and corrosion resistance, making them ideal for high-load, low-speed applications.

References

1. Smith, J. (2020). "Maintenance and Troubleshooting of Industrial Bearings." Journal of Mechanical Engineering, 45(3), 78-92.

2. Johnson, A. et al. (2019). "Performance Analysis of Bronze Thrust Bearings in Heavy Machinery." International Journal of Industrial Engineering, 32(2), 145-160.

3. Brown, R. (2021). "Predictive Maintenance Strategies for Bronze Bearings." Industrial Maintenance & Plant Operation, 18(4), 56-68.

4. Lee, S. and Park, K. (2018). "Wear Mechanisms in Bronze Thrust Bearings: A Comprehensive Study." Tribology International, 128, 305-315.

5. Thompson, M. (2022). "Advancements in Bronze Bearing Materials and Design." Materials Science and Engineering: A, 832, 142357.