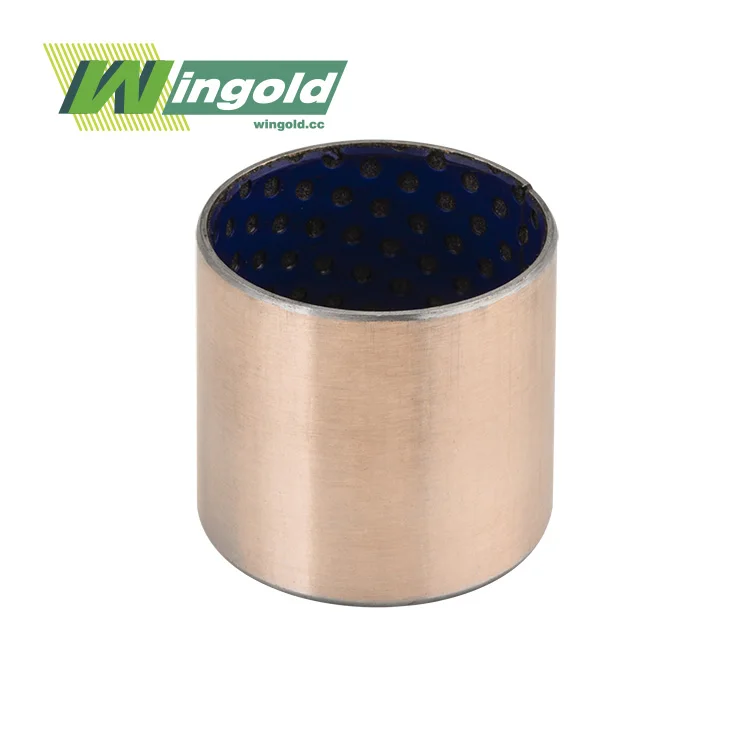

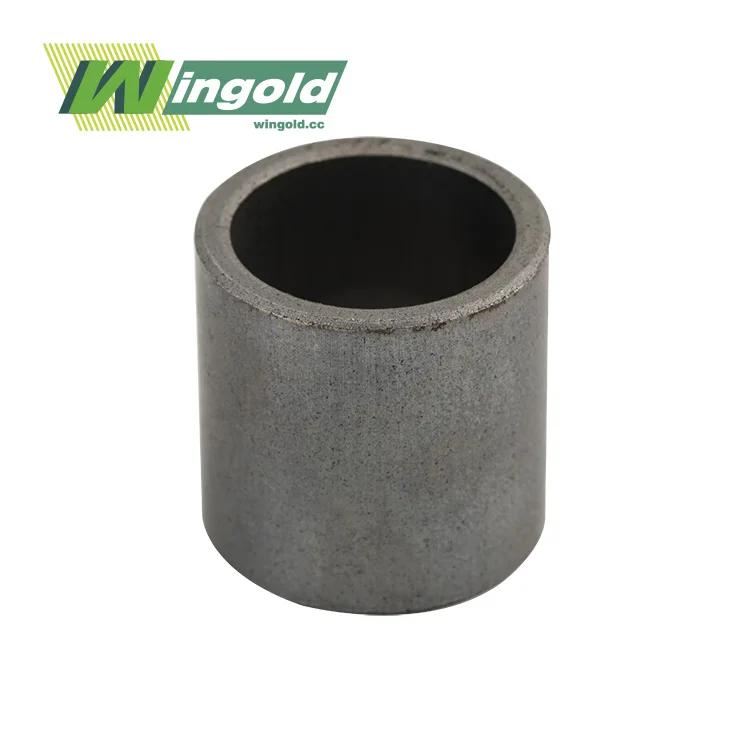

Understanding Bronze Shoulder Bushings: Key Features and Applications

Bronze shoulder bushings are indispensable components in various industrial applications, offering a unique combination of strength, wear resistance, and self-lubricating properties. These meticulously engineered bearings feature a distinctive shoulder structure that facilitates precise positioning and enhances load distribution. Manufactured from premium bronze alloys such as C93200 (SAE 660) and C86300, these bushings exhibit exceptional durability and corrosion resistance.

Composition and Technical Specifications

The composition of bronze shoulder bushings—often used alongside durable copper sleeve bushings—plays a crucial role in their overall performance. High-density copper alloy bases, typically CuSn8P0.3 or CuSn6.5P0.1, form the foundation of these bearings. These materials offer a balance of strength and malleability, essential for withstanding heavy loads and maintaining dimensional stability. The technical specifications of bronze shoulder bushings are equally impressive:

- Hardness: Standard HB90-120, with hardened options reaching HB120-150

- Operating Temperature Range: -80°C to 200°C

- Maximum Load Pressure: 75N/mm²

- Maximum Sliding Speed: 2.5m/s

- Inner Diameter: 10mm - 150mm

- Outer Diameter: 15mm - 200mm

- Length: 20mm - 300mm

- Shoulder Width: 2mm - 15mm

- Surface Finish: Ra 0.8 - 3.2 μm

- Load Capacity: Up to 140 MPa

Applications Across Industries

The versatility of bronze shoulder bushings makes them invaluable in numerous industries. They find extensive use in hydraulic and pneumatic systems, forging and pressing machine tools, plastic machinery, and lifting equipment. These bushings are also critical components in port machinery, office equipment, fitness machinery, and textile production lines. Their reliability and durability make them ideal for demanding applications in the food processing, chemical, and papermaking industries. Additionally, bronze shoulder bushings play vital roles in automotive manufacturing, railway locomotives, shipbuilding, metallurgical machinery, and engineering equipment.

Criteria for Selecting Top-Tier Bronze Shoulder Bushings Manufacturers

Choosing the right manufacturer for bronze shoulder bushings is paramount to ensuring the quality and reliability of your mechanical systems. When evaluating potential suppliers, consider the following criteria:

Manufacturing Capabilities and Quality Control

Look for manufacturers with advanced production facilities, including CNC machining centers and centrifugal casting production lines. A robust quality control system, encompassing friction coefficient testing and life acceleration testing, is essential. Ensure that the manufacturer's products comply with international standards such as ISO 4383 and ASTM B22. The ability to produce a wide range of bushing types and materials, including oil-free options, demonstrates versatility and expertise.

Customization and Technical Support

Opt for manufacturers that offer customized solutions tailored to your specific requirements. The ability to produce bushings through various methods—turning, injection molding, extrusion, stamping, forging, or milling—indicates flexibility and technical prowess. Look for suppliers that provide one-to-one technical support from experienced engineers throughout the production process, ensuring that your unique needs are met with precision.

Production Capacity and Delivery Efficiency

Consider manufacturers with substantial production capacity, capable of handling large-scale orders while maintaining quality. For instance, a manufacturer with an annual production capacity of 10,000 tons demonstrates significant capabilities. Efficient production processes and streamlined logistics are crucial for ensuring fast turnaround times and reliable delivery. This efficiency can help you optimize your inventory management and reduce overall costs.

Advantages of Partnering with Reputable Bronze Shoulder Bushings Suppliers

Collaborating with established bronze shoulder bushings suppliers offers numerous benefits that can significantly impact your operations and bottom line.

Enhanced Product Reliability and Performance

Reputable manufacturers design their bearings for superior performance, ensuring long service life and maintenance-free operation. The use of high-quality materials and advanced manufacturing techniques results in bushings with exceptional load-bearing capacity, reduced friction, and remarkable wear resistance. This reliability translates to increased uptime and reduced maintenance costs for your equipment.

Environmental and Economic Benefits

Many top-tier manufacturers offer self-lubricating bronze shoulder bushings, eliminating the need for external lubricants. This feature not only contributes to a cleaner environment but also reduces ongoing maintenance requirements and associated costs. The durability of high-quality bushings means fewer replacements over time, further enhancing the economic benefits of choosing a reputable supplier.

Flexible Ordering and Comprehensive Support

Leading manufacturers often offer flexible ordering options, accommodating smaller minimum order quantities. This flexibility allows you to test products or maintain lower inventory levels without significant financial commitment. Additionally, comprehensive technical support and after-sales service ensure that you have expert assistance throughout the lifespan of the product, from selection to implementation and beyond.

Conclusion

Selecting the right bronze shoulder bushings manufacturer is crucial for ensuring the quality, reliability, and efficiency of your mechanical systems. By partnering with a reputable supplier like Wingold Bearing, you gain access to high-quality products, customized solutions, and expert support that can drive your operations forward. With our extensive industry experience, advanced manufacturing capabilities, and commitment to customer satisfaction, we stand ready to meet your custom bronze bushings needs with precision and excellence. For more information about our products and services, please contact us at info@wingold.cc. Trust Wingold Bearing as your premier bronze shoulder bushings supplier and manufacturer, and experience the difference that quality and expertise can make in your industrial applications.

FAQs

What are the key advantages of using bronze shoulder bushings?

Bronze shoulder bushings offer excellent load-bearing capacity, reduced friction, wear resistance, and self-lubricating properties. They provide precise positioning and enhanced load distribution, making them ideal for various industrial applications.

How do I determine the right size of bronze shoulder bushings for my application?

To determine the correct size, consider factors such as the shaft diameter, load requirements, and operating conditions. Consult with a reputable manufacturer like Wingold Bearing for expert guidance in selecting the optimal bushings for your specific needs.

Are bronze shoulder bushings suitable for high-temperature applications?

Yes, many bronze shoulder bushings can operate in temperatures ranging from -80°C to 200°C, making them suitable for a wide range of applications, including those involving high temperatures.