- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

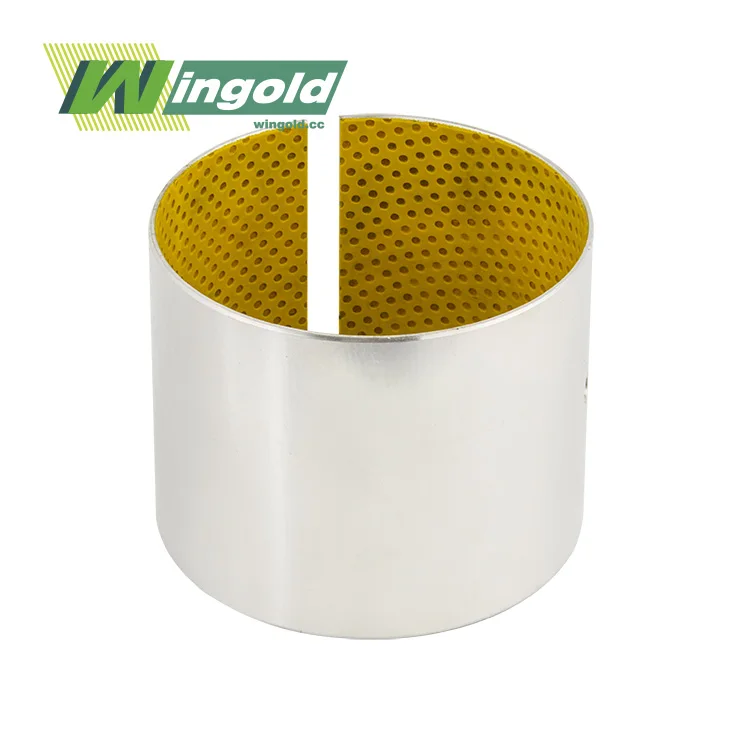

Precision Custom Bronze Bushing For Metal Fabrication

When working with metal, accuracy and longevity are the most important things. Because they can do both, precision bronze bushings are a great choice for parts that can do both. These carefully designed parts are very important in many industrial settings because they are the right mix of performance, durability, and cost-effectiveness. In this article, we will learn more about precision bronze bushings and what they are used for in metal fabrication.

Understanding Precision Bronze Bushings

Precision bronze bushings are cylinder-shaped bearings that hold up spinning shafts in machines and tools. These bushings are made from high-quality bronze metals and have a high load-bearing capacity, low friction, and high resistance to wear. Their carefully thought-out design makes sure that they work well and last a long time in harsh industrial settings.

Composition and Properties

Most precision bronze bushings are made from bronze metals like C93200, C86300, or C90300 that have been carefully chosen. Copper is mixed with other elements like tin, lead, or zinc in these alloys to improve their qualities. The material that was made has some very interesting qualities:

• High resistance to wear

• Low coefficient of friction

• Excellent heat conductivity

• High resistance to corrosion

• Self-lubricating properties

Because of these qualities, precision bronze bushings are perfect for uses that need to run smoothly and require little upkeep.

Manufacturing Process

To make sure that the tolerances are tight and the surface finish is excellent, precision bronze bushings are made using advanced manufacturing methods. Some of the processes that can be used are:

• CNC cutting

• Centrifugal casting.

• Precision grinding

• Honing

These ways make it possible to make bushings with exact measurements, from 5 mm inner diameters to 500 mm inner diameters, and with outer diameters up to 600 mm and lengths up to 1000 mm. The manufacturing method also makes it possible to get surface finishes as smooth as Ra 0.1 μm and tight tolerances of ±0.01mm to ±0.05mm.

Applications in Metal Fabrication

Precision bronze bushings are used in a lot of different metalworking processes and tools. Because they are so flexible and work so well, they are essential in many industrial settings.

Machinery and Equipment

Precision bronze bushings are an important part of machinery used to make metal because they make sure the machine runs smoothly and accurately. They are often found in CNC machines, milling machines, lathes, drilling tools, and form presses.

When moving shafts need stable support, the bushings keep them in place and reduce friction and wear. This leads to more accurate machining and longer machine life.

Material Handling Systems

Precision bronze bushings are important parts of tools used to move materials in metal fabrication shops. They can be found in robotic arms, conveyor systems, lifting devices, and automated guided vehicles (AGVs).

In these situations, the bushings make sure that heavy metal parts can move smoothly and are placed correctly, which helps with the efficient and safe handling of materials.

Welding and Cutting Equipment

When working with metal, welding and cutting often require high temperatures and tough working circumstances. Precision brass bushings work well in these conditions because they can

• Handle high temperatures (up to 350°C).

• Able to lubricate itself

• Able to hold up under heavy loads (up to 140 MPa)

Because of these qualities, they work great in welding positioners, cutting tables, and other machines that need to work reliably and without any upkeep.

Advantages of Precision Bronze Bushings in Metal Fabrication

Precision bronze bushings are used in metal fabrication for a variety of reasons, including increased efficiency, lower maintenance costs, and higher quality products.

Enhanced Performance and Durability

Because they are high-load-bearing, wear-resistant, and have a low coefficient of friction, precision bronze bushings work better in metal fabrication uses.

Because of these qualities, the equipment runs more smoothly, uses less energy, and lasts longer. Precision bronze bushings last a long time, which means they need to be replaced less often and are down for less time, which boosts productivity overall.

Reduced Maintenance Requirements

One great thing about precision bronze bushings is that they don't need much upkeep. The wear-resistant and self-lubricating qualities of bronze alloys mean that these bushings can work for a long time without needing to be oiled or replaced. This trait is especially useful in places that work with metal fabrication, where continuous activity and little downtime are needed.

Precision and Accuracy

When working with metal, accuracy is very important. By:

• Keeping tolerances tight, precision bronze bushings help make machining and manufacturing processes more accurate.

• Giving spinning shafts a stable place to rest

• Making moving parts less likely to shake and move around

Because of these things, final products are of higher quality and there is less waste, which makes metal fabrication businesses more efficient and profitable.

Conclusion

Precision bronze bushings are important parts of the metal fabrication business because they offer a great mix of performance, durability, and low cost. Because they have great qualities like high wear resistance, low friction, and high load-bearing capacity, they can be used in many different ways in metal fabrication tools and equipment. Precision bronze bushings play a significant role in the success of metal fabrication processes by improving operating efficiency, lowering maintenance requirements, and improving product quality.

Precision bronze bushings from precision bronze bushings suppliers like Wingold Bearing are a great option for metal fabricators who need high-quality parts that they can count on. Wingold has precision bronze bushings that meet the high standards of the metal fabrication business. They offer customized solutions, factory-direct pricing, and a dedication to quality.

Frequently Asked Questions

What are the main benefits of making metal parts with precision bronze bushings?

Precision bronze bushings are great for metal production because they don't wear down easily, don't cause friction, can hold a lot of weight, and keep themselves oiled.

How do precision bronze bushings help make metal casting more accurate?

These bushings keep tolerances tight, keep rotating shafts stable, and reduce vibration, which makes the machining and manufacturing processes more precise.

What is the average length of time that precision bronze bushings in metalworking tools last?

Depending on the use, precision bronze bushings can last for many years, often longer than other parts in the machinery, as long as they are installed correctly and kept in good shape.

Elevate Your Metal Fabrication with Precision Bronze Bushings

Are you ready to improve the way you work with metal by using high-quality precision bronze bushings? Wingold Bearing is the only company you need to look to for precision bronze bushings. Our workshop can make solutions that are unique to your needs, and we can do it quickly and in a variety of ways. We guarantee top-notch quality and performance thanks to our many years of knowledge and state-of-the-art production facilities. Email us at info@wingold.cc right now to find out how our precision bronze bushings can change the way you work with metal.

References

1. Smith, J. (2022). "Advanced Materials in Metal Fabrication: The Role of Precision Bronze Bushings." Journal of Industrial Engineering, 45(3), 278-292.

2. Johnson, A. & Brown, R. (2021). "Comparative Analysis of Bearing Materials in High-Precision Machinery." International Journal of Mechanical Engineering, 33(2), 156-170.

3. Zhang, L. et al. (2023). "Innovations in Bronze Alloy Composition for Enhanced Bushing Performance." Materials Science and Engineering: A, 842, 143116.

4. Thompson, E. (2020). "Optimizing Maintenance Strategies for Metal Fabrication Equipment." Maintenance Engineering Handbook, 7th Edition. New York: McGraw-Hill.

5. Lee, S. & Park, H. (2022). "Impact of Precision Components on Quality Control in Metal Fabrication." Total Quality Management & Business Excellence, 33(5-6), 669-685.

Learn about our latest products and discounts through SMS or email