Grasping Bronze Bushing Lubrication: Principles and Benefits

The Science Behind Bronze Bushing Lubrication

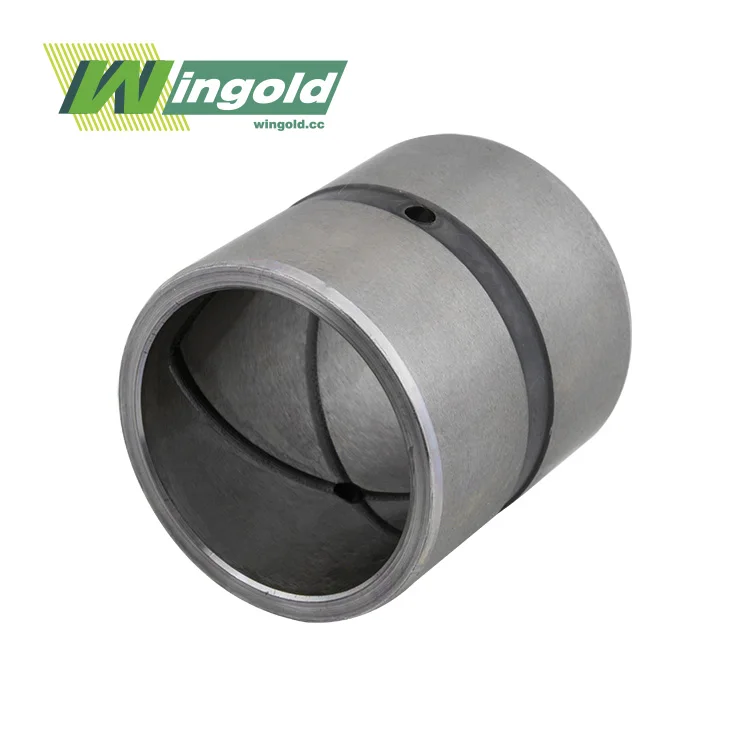

Bronze bushing lubrication operates on the principle of hydrodynamic lubrication. This process involves creating a thin film of lubricant between the bushing and the shaft, effectively separating the two surfaces. As the shaft rotates, it draws the lubricant into the load-bearing area, forming a wedge-shaped film that supports the load and minimizes direct metal-to-metal contact.

The efficacy of bronze bushing lubrication depends on several factors:

- Lubricant viscosity

- Rotational speed

- Applied load

- Surface finish of the bushing and shaft

When these elements are optimized, the lubrication system can significantly reduce friction, wear, and energy consumption. Properly balanced lubrication parameters ensure that moving parts operate smoothly, minimizing direct contact and heat generation. This not only extends the lifespan of critical components but also improves overall system efficiency. As a result, operational costs decrease, equipment reliability increases, and the entire production process benefits from enhanced performance and stability.

Advantages of Proper Bronze Bushing Lubrication

Implementing an effective bronze bushing lubrication strategy offers numerous benefits:

- Reduced friction and wear

- Extended component lifespan

- Improved energy efficiency

- Enhanced load-bearing capacity

- Corrosion protection

- Heat dissipation

- Noise reduction

These advantages contribute to improved overall system performance and reduced maintenance requirements, ultimately leading to cost savings and increased productivity. By enhancing reliability and minimizing unexpected downtime, they allow operations to run more smoothly and efficiently. Additionally, fewer maintenance interventions mean lower labor costs and less disruption to production schedules, helping businesses maintain a competitive edge in demanding industrial environments.

Advanced Lubricant Technologies for Bronze Bushings

Synthetic Lubricants: The Future of Bronze Bushing Lubrication

The evolution of lubricant technology has led to the development of synthetic lubricants specifically designed for bronze bushings. These advanced formulations offer superior performance characteristics compared to traditional mineral-based oils:

- Higher viscosity index for improved temperature stability

- Enhanced oxidation resistance for longer service life

- Superior load-carrying capacity

- Improved water resistance

- Better low-temperature fluidity

Synthetic lubricants can maintain their performance across a wider temperature range (-40°C to 200°C), making them ideal for applications subjected to extreme conditions. Unlike mineral oils, they resist thermal degradation and oxidation, ensuring consistent lubrication even under high loads or fluctuating temperatures. This stability helps reduce component wear, minimize downtime, and extend equipment life, ultimately improving operational efficiency in harsh or demanding industrial environments.

Nano-Enhanced Lubricants: Pushing the Boundaries of Performance

Emerging nano-enhanced lubricants represent the cutting edge of bronze bushing lubrication technology. These lubricants incorporate nano-sized particles, such as graphene or molybdenum disulfide, to further enhance their tribological properties:

- Exceptional anti-wear characteristics

- Reduced friction coefficient

- Improved thermal conductivity

- Enhanced extreme pressure performance

The nano-particles act as tiny ball bearings, filling in microscopic surface irregularities and providing an additional layer of protection against wear and friction. By smoothing out these imperfections, they help reduce direct metal-to-metal contact, which lowers operating temperatures and enhances overall efficiency. This added protective effect contributes to extended component lifespan, improved reliability, and reduced maintenance needs in demanding industrial environments.

Optimizing Bronze Bushing Lubrication for Industrial Applications

Selecting the Right Lubricant for Your Bronze Bushings

Choosing the appropriate lubricant is crucial for maximizing the performance and longevity of bronze bushings. Factors to consider include:

- Operating temperature range

- Load conditions

- Environmental factors (e.g., humidity, contaminants)

- Rotational speed

- Desired service intervals

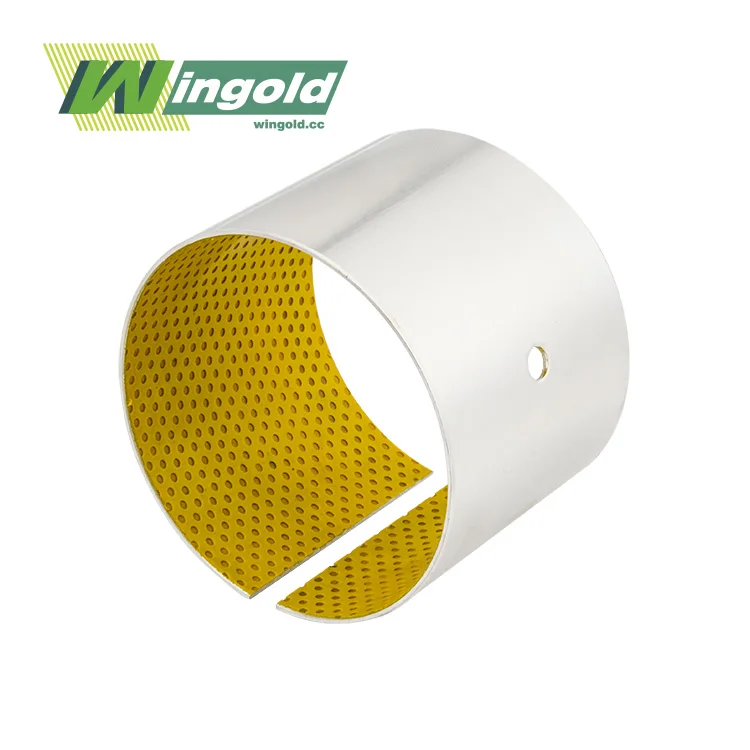

High-density copper alloy bushings with diamond or hemispherical oil indentations require specialized lubricants that can effectively utilize these surface features to maintain a consistent oil film. These indentations are designed to store and distribute lubricant evenly across the contact surfaces, reducing friction and wear. Selecting lubricants with the right viscosity and additive package ensures that the oil remains stable, supporting smooth and reliable equipment operation over time.

Implementing Effective Lubrication Practices

To maximize the benefits of bronze bushing lubrication:

- Establish a regular lubrication schedule based on operating conditions and manufacturer recommendations

- Use proper lubrication techniques to ensure even distribution of lubricant

- Monitor lubricant condition and replenish or replace as needed

- Keep bushings and surrounding areas clean to prevent contamination

- Implement condition monitoring techniques to detect early signs of lubrication issues

By taking after these hones, you can guarantee ideal execution and life span of your bronze bushings over different mechanical applications. Legitimate support and opportune oil offer assistance diminish contact and wear, whereas customary assessments permit early location of potential issues. These steps contribute to smoother hardware operation, minimize unforeseen downtime, and eventually ensure your venture in apparatus, guaranteeing solid execution indeed beneath requesting working conditions.

Leveraging Advanced Lubrication Systems

Modern lubrication systems can further enhance the effectiveness of bronze bushing lubrication:

- Automated lubrication systems for consistent and precise lubricant delivery

- Oil mist lubrication for hard-to-reach or high-speed applications

- Centralized lubrication systems for efficient management of multiple lubrication points

- Condition monitoring sensors for real-time lubrication status updates

These progressed frameworks can offer assistance optimize grease forms, decrease manual labor, and anticipate lubrication-related disappointments. By naturally conveying the right sum of grease at the right time, they guarantee steady gear execution and minimize the dangers of over- or under-lubrication. This not only amplifies the life expectancy of basic apparatus but also progresses operational effectiveness. Furthermore, computerized oil diminishes human mistake, contributing to more secure and more solid mechanical operations in general.

Conclusion

Bronze bushing lubrication is a critical aspect of maintaining efficient and reliable mechanical systems across various industries. By understanding the principles of lubrication, leveraging advanced lubricant technologies, and implementing effective lubrication practices, businesses can significantly improve the performance, longevity, and cost-effectiveness of their equipment.

As technology continues to evolve, staying informed about the latest developments in bronze bushing lubrication will be essential for maintaining a competitive edge in industrial operations. For more information on optimizing your bronze bushing lubrication strategy or to explore our range of high-performance lubricants, please contact us at info@wingold.cc. Our team of experts is ready to help you achieve peak performance in your industrial applications.