Introducing the Technology Behind Self-Lubricating Bronze Bushings

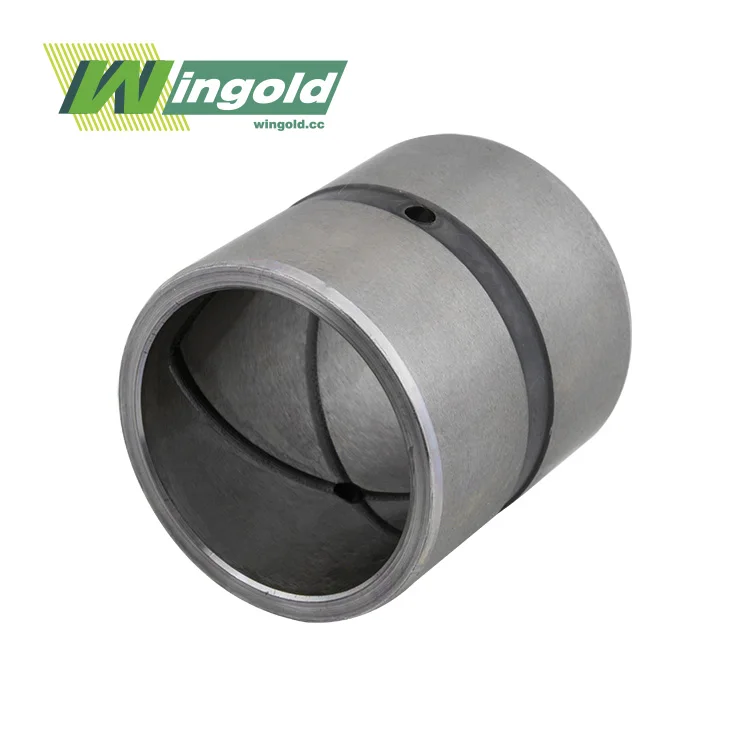

The Composition and Structure of Self-Lubricating Bronze Bushings

Self-lubricating bronze bushings, especially those with a 1-inch internal breadth (ID), are built utilizing high-quality bronze combinations such as SAE 660 or SAE 620. These amalgams are chosen for their remarkable mechanical properties, including high quality, solidness, and predominant wear resistance. The composition regularly incorporates copper as the essential component, with augmentations of tin, lead, and other metals to upgrade particular characteristics.

The key to the self-lubricating property lies in the bushing's porous structure. During the manufacturing process, tiny pores are created throughout the material. These microscopic voids are then impregnated with oil, creating a reservoir of lubricant within the bushing itself. This unique structure allows the bushing to release small amounts of lubricant during operation, ensuring continuous lubrication without external intervention.

The Science of Self-Lubrication in Bronze Bushings

The self-lubrication process in bronze bushings is a fascinating interplay of material science and tribology. As the shaft rotates within the bronze bushing 1 ID, the friction and heat generated cause a slight expansion of the bronze material. This expansion forces a small amount of oil from the pores onto the bearing surface, creating a thin film of lubricant between the shaft and the bushing.

This oil film serves multiple purposes. It reduces friction between the moving parts, dissipates heat, and prevents direct metal-to-metal contact. As the system cools or when the load is reduced, the bronze contracts slightly, and the pores reabsorb excess oil, ready for the next cycle. This continuous process ensures optimal lubrication throughout the bushing's operational life, significantly reducing wear and extending the component's longevity.

The Economic Impact of Self-Lubricating Bronze Bushings

Reduced Downtime and Increased Productivity

One of the most significant economic benefits of using self-lubricating bronze bushing 1 ID is the substantial reduction in equipment downtime. Traditional bushings require regular lubrication, often necessitating machine shutdowns for maintenance. These interruptions can be costly, especially in high-volume production environments or critical systems where every minute of operation counts.

Self-lubricating bushings eliminate the need for these frequent maintenance stops. The continuous, automatic lubrication provided by the bushing's porous structure ensures that the component remains adequately lubricated without manual intervention. This translates to longer periods of uninterrupted operation, increased machine availability, and ultimately, higher productivity and output.

Lower Labor Costs and Simplified Maintenance Procedures

The implementation of self-lubricating bronze bushings leads to a significant reduction in labor costs associated with maintenance. Traditional bushings require regular attention from maintenance personnel for lubrication, inspection, and replacement. This not only incurs direct labor costs but also requires the allocation of skilled technicians who could be utilized for more complex tasks.

With self-lubricating bushings, the maintenance schedule is greatly simplified. The need for regular lubrication is eliminated, and the frequency of inspections can be reduced due to the bushing's longer service life. This allows maintenance teams to focus on other critical areas, optimizing the overall efficiency of maintenance operations and reducing labor costs.

Extended Component Lifespan and Reduced Replacement Costs

The superior wear resistance and consistent lubrication of self-lubricating bronze bushings contribute to a significantly extended operational lifespan. These bushings can often outlast traditional alternatives by several times, depending on the application and operating conditions. This longevity translates directly into reduced replacement costs.

Fewer replacements mean not only savings on the cost of new components but also reductions in associated expenses such as inventory carrying costs, installation labor, and potential production losses during replacement procedures. Over time, these savings can amount to substantial sums, especially in large-scale operations or applications with numerous bushing points.

Optimal Applications and Considerations for Self-Lubricating Bronze Bushings

Ideal Industries and Machinery for Self-Lubricating Bronze Bushings

Self-lubricating bronze bushing 1 ID find optimal application in a wide range of industries and machinery types. They are particularly well-suited for equipment operating in challenging environments or where regular maintenance access is difficult. Some key applications include:

- Heavy machinery in construction and mining

- Agricultural equipment exposed to dust and debris

- Food processing machinery requiring clean, grease-free operation

- Marine applications exposed to corrosive environments

- Textile machinery with high-speed, continuous operation

- Automotive components subject to varied loads and temperatures

These bushings excel in situations where traditional lubrication methods are impractical, costly, or potentially contaminating to the end product. Their ability to operate reliably with minimal maintenance makes them invaluable in remote or hard-to-reach installations.

Factors to Consider When Implementing Self-Lubricating Bronze Bushings

While self-lubricating bronze bushings offer numerous advantages, their successful implementation requires careful consideration of several factors:

- Load Capacity: Ensure the bushing's load-bearing capabilities match the application requirements. Self-lubricating 1 ID bronze bushings can typically handle loads up to 4,000 psi (27.6 MPa), but this can vary based on the specific alloy and design.

- Operating Temperature: Consider the temperature range of the application. Most bronze bushings perform well from -40°C to 150°C, but extreme temperatures may affect lubrication effectiveness.

- Shaft Material and Finish: The mating shaft's material and surface finish can impact the bushing's performance. Harder shaft materials with smooth finishes generally yield better results.

- Environmental Factors: While bronze bushings offer good corrosion resistance, extremely corrosive or contaminated environments may require additional protective measures.

- Speed and PV Factor: Consider the rotational speed and the product of pressure and velocity (PV factor) to ensure the bushing can handle the operational conditions without overheating.

By carefully evaluating these factors and selecting the appropriate self-lubricating bronze bushing, businesses can maximize the benefits of reduced maintenance costs and improved operational efficiency.

Conclusion

Self-lubricating bronze bushing 1 ID represent a significant advancement in bearing technology, offering a compelling solution for reducing maintenance costs across various industries. By eliminating the need for regular lubrication, extending component lifespan, and simplifying maintenance procedures, these bushings provide substantial economic benefits. Their ability to operate reliably in challenging environments makes them an invaluable asset in modern machinery design.

As industries continue to seek ways to optimize operations and reduce costs, the adoption of self-lubricating bronze bushings is likely to increase. Their unique combination of durability, low maintenance requirements, and cost-effectiveness positions them as a key component in the drive towards more efficient and economical industrial processes.

For more information on how self-lubricating 1 ID bronze bushings can benefit your specific application and reduce your maintenance costs, please contact us at info@wingold.cc. Our team of experts is ready to assist you in selecting the optimal bearing solution for your needs.