The Anatomy of Brass Flanged Sleeve Bearings

Composition and Structure

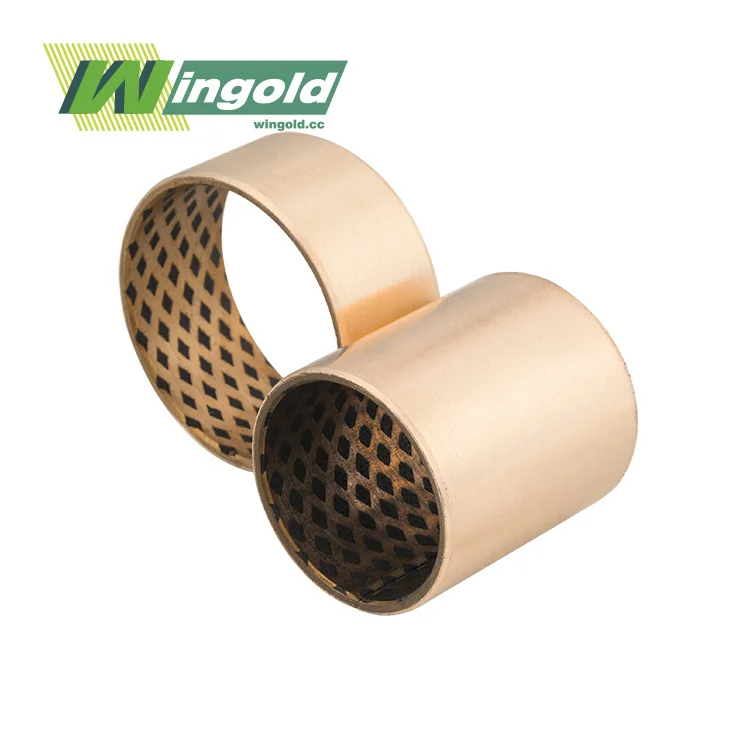

Brass flanged sleeve bearings are meticulously engineered components, crafted from high-quality brass alloys such as C93200 (SAE 660) or C86300. These alloys are carefully selected for their optimal balance of strength, wear resistance, and self-lubricating properties. The bearing's structure typically consists of a cylindrical sleeve with an integrated flange at one end. This unique design provides additional support and helps maintain proper alignment, significantly reducing the risk of misalignment and premature wear.

Self-Lubricating Properties

One of the most remarkable features of brass flanged sleeve bearings is their inherent self-lubricating capability. This is achieved by embedding graphite or other solid lubricants directly into the brass matrix during manufacturing. As the bearing operates under load and heat, these lubricants gradually release, creating a thin, continuous lubricating film on the bearing surface. This film significantly reduces friction and wear, allowing for smooth, reliable operation even in high-temperature environments where conventional liquid lubricants would degrade or evaporate quickly.

Dimensional Stability

Dimensional stability is critical in high-temperature applications to ensure machinery operates within precise tolerances. Brass flanged sleeve bearings demonstrate outstanding thermal stability, maintaining their exact shape and dimensions even under severe heat exposure. This resistance to thermal expansion and deformation helps preserve the bearing's fit and function, preventing issues like excessive clearance or binding. Consequently, this stability supports consistent machine performance, reduces maintenance needs, and extends the overall lifespan of industrial equipment operating in demanding thermal conditions.

Advantages in High-Temperature Applications

Thermal Conductivity

Brass is renowned for its excellent thermal conductivity, a property that makes brass flanged sleeve bearings particularly well-suited for high-temperature applications. This high thermal conductivity allows for efficient heat dissipation, preventing localized hot spots and reducing the overall operating temperature of the bearing. As a result, the bearing can maintain its performance characteristics even in challenging thermal environments, outperforming many other bearing materials.

Corrosion Resistance

High-temperature environments often go hand-in-hand with corrosive conditions. Brass flanged sleeve bearings offer superior corrosion resistance compared to many other bearing materials. This resistance is particularly valuable in industrial settings where exposure to chemicals, moisture, or other corrosive elements is common. The ability to withstand corrosion ensures the longevity of the bearing and the machinery it supports, reducing the need for frequent replacements and minimizing downtime.

Load-Bearing Capacity

Despite their relatively lightweight construction, brass flanged sleeve bearings boast impressive load-bearing capacities that rival heavier materials. The flanged design enhances this strength by distributing loads evenly across a larger surface area, providing crucial additional support. In high-temperature and high-stress applications, such as heavy industrial machinery, this robust load-bearing capability ensures operational integrity, minimizes wear, and helps prevent premature bearing or equipment failure, ultimately extending service life and improving reliability under demanding conditions.

Applications and Industries

Automotive and Aerospace

In the automotive and aerospace industries, brass flanged sleeve bearings find extensive use in various high-temperature applications. They are commonly employed in turbochargers, exhaust systems, and engine components where temperatures can reach extreme levels. The bearings' ability to maintain performance under these conditions, coupled with their self-lubricating properties, makes them invaluable in ensuring the reliability and efficiency of these critical systems.

Industrial Machinery

Industrial machinery frequently operates under challenging conditions, such as elevated temperatures and heavy mechanical loads. Brass flanged sleeve bearings are widely used across various industrial sectors, including furnace equipment, steel mills, and glass manufacturing. Their remarkable durability, thermal stability, and low maintenance requirements make them well-suited for these demanding environments. By ensuring reliable performance, these bearings contribute to increased equipment uptime, enhanced productivity, and reduced operational costs in heavy-duty industrial processes.

Power Generation

In the power generation industry, equipment must endure extreme temperatures and continuous, demanding operation. Brass flanged sleeve bearings are essential components in this sector, serving in critical applications like turbine bearings and generator supports. Their excellent wear resistance and ability to perform reliably under high temperatures help maintain smooth, efficient functioning of power generation machinery. This reliability minimizes downtime and supports consistent energy production, ultimately improving overall operational efficiency and equipment longevity.

Conclusion

Brass flanged sleeve bearings represent a superior choice for high-temperature applications across various industries. Their unique combination of thermal conductivity, self-lubrication, corrosion resistance, and load-bearing capacity makes them indispensable in environments where other bearing materials might falter. By opting for brass flanged sleeves in high-temp uses, industries can benefit from extended equipment life, reduced maintenance requirements, and improved operational efficiency.

For more information on how brass flanged sleeve bearings can benefit your high-temperature applications, or to discuss custom solutions tailored to your specific needs, please don't hesitate to contact us at info@wingold.cc. Our team of experts is ready to help you find the perfect bearing solution for your unique requirements.

FAQ

What temperature range can brass flanged sleeve bearings withstand?

Typically, brass flanged sleeve bearings can operate effectively in temperatures ranging from -40°C to 150°C, depending on the specific alloy composition.

How do brass flanged sleeve bearings compare to other bearing types in high-temperature applications?

Brass flanged sleeve bearings often outperform other bearing types in high-temperature applications due to their excellent thermal conductivity, self-lubricating properties, and corrosion resistance.

Are brass flanged sleeve bearings suitable for continuous high-temperature operation?

Yes, these bearings are designed for continuous operation in high-temperature environments, making them ideal for applications requiring long-term reliability under extreme conditions.