The Unique Structure and Properties of Teflon Lined Bushings

Teflon lined bushings boast a sophisticated three-layer structure that contributes to their outstanding performance in high-temperature applications. Let's delve into the composition and roles of each layer:

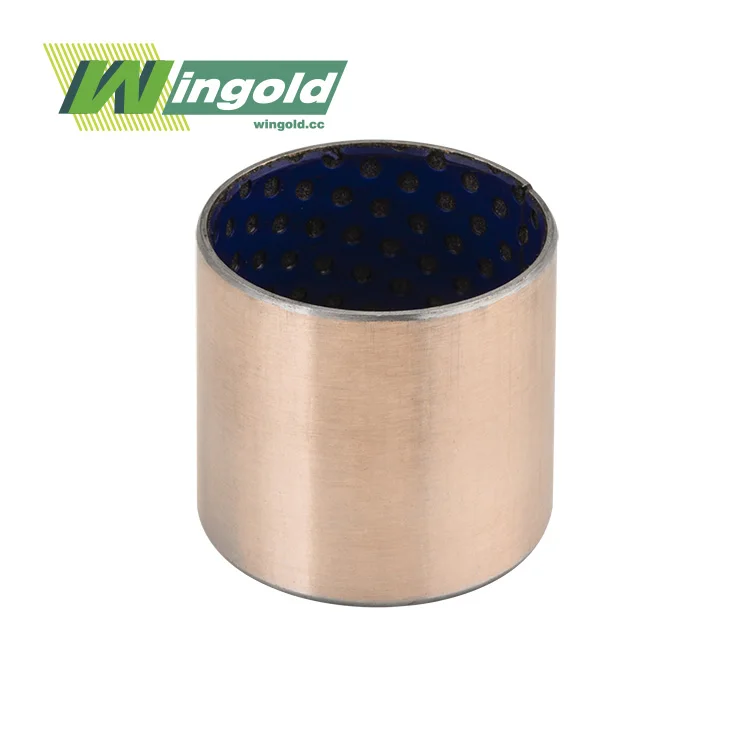

Steel Backing: The Foundation of Strength

The outermost layer of a Teflon lined bushing is typically made of steel. This robust backing serves two crucial functions. Firstly, it provides the necessary structural integrity to withstand high loads and pressures encountered in industrial applications. Secondly, it facilitates proper positioning during assembly, ensuring the bushing fits securely within its housing.

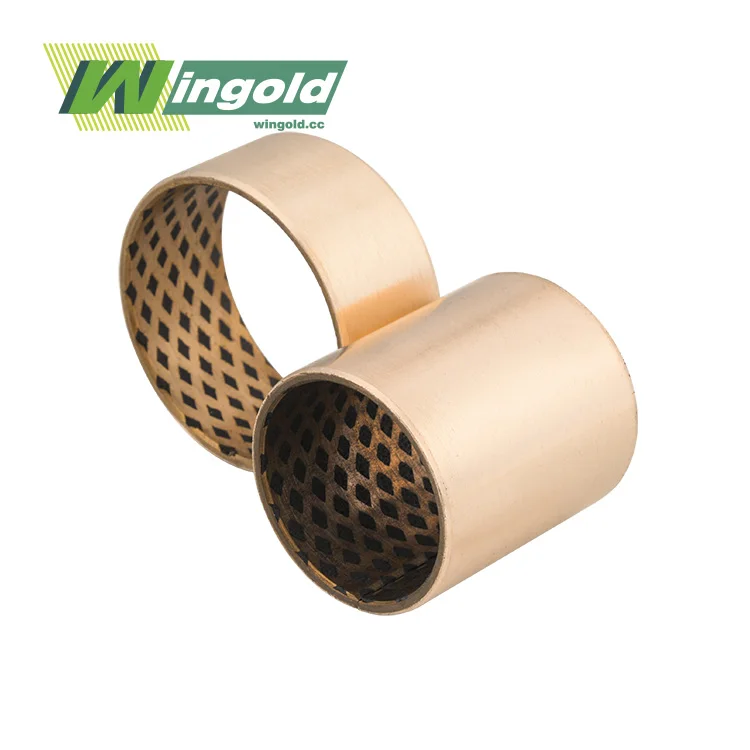

Porous Bronze: The Crucial Intermediate Layer

Sandwiched between the steel backing and the Teflon layer in Teflon lined bushings is a layer of porous bronze. This intermediate layer plays a vital role in the bushing's performance. The porous nature of the bronze allows it to act as a reservoir for lubricants, enhancing the self-lubricating properties of the bushing. Moreover, it serves as a transitional layer, promoting strong adhesion between the steel backing and the Teflon surface.

PTFE Layer: The Star of the Show

The innermost layer, composed of PTFE or Teflon, is where the magic happens. This layer is responsible for the bushing's exceptional low-friction and wear-resistant properties. PTFE's unique molecular structure gives it an incredibly low coefficient of friction, allowing for smooth operation even under high temperatures and loads. Additionally, its chemical inertness makes it resistant to corrosion and degradation in harsh environments.

The synergy between these three layers results in a bushing that can withstand high temperatures while providing superior performance. The steel backing ensures durability, the porous bronze enhances lubrication, and the PTFE layer delivers unparalleled friction reduction and wear resistance.

Advantages of Teflon Lined Bushings in High-Temperature Environments

Teflon lined bushings offer a plethora of benefits that make them indispensable in high-temperature applications. Let's explore some of these advantages:

Exceptional Temperature Resistance

One of the most remarkable features of Teflon lined bushings is their ability to maintain performance across an extensive temperature range. These bushings can operate efficiently from cryogenic temperatures as low as -200°C up to scorching highs of +280°C. This wide temperature tolerance makes them suitable for diverse applications, from aerospace to industrial furnaces.

Self-Lubricating Properties

The PTFE layer in Teflon lined bushings provides inherent self-lubricating properties. This characteristic eliminates the need for external lubrication, which is particularly advantageous in high-temperature environments where conventional lubricants may break down or evaporate. The self-lubricating nature ensures consistent performance and reduces maintenance requirements.

Low Friction and Wear Resistance

Teflon's extremely low coefficient of friction, ranging from 0.02 to 0.08, results in minimal energy loss due to friction. This low friction translates to smoother operation, reduced wear, and extended component life. The wear rate of less than 20 μm/km further underscores the durability of these bushings in high-temperature applications.

Chemical Resistance

PTFE's chemical inertness makes Teflon lined bushings resistant to a wide range of chemicals, acids, and solvents. This property is particularly valuable in high-temperature environments where corrosive substances may be present, ensuring the longevity and reliability of the bushings.

Load Capacity

Despite their low-friction properties, Teflon lined bushings do not compromise on load-bearing capacity. With the ability to handle loads up to 140 MPa, these bushings can withstand significant pressures in high-temperature applications without deformation or failure.

Applications and Industries Benefiting from Teflon Lined Bushings

The unique properties of Teflon lined bushings make them suitable for a wide range of high-temperature applications across various industries. Let's explore some key areas where these bushings shine:

Aerospace and Aviation

In the aerospace industry, where components must withstand extreme temperatures and operate with utmost reliability, Teflon lined bushings find extensive use. They are employed in aircraft landing gear, flap mechanisms, and engine mounts, where their ability to perform under high temperatures and loads is critical.

Automotive Manufacturing

The car division leverages Teflon lined bushings in different high-temperature applications. These incorporate debilitate framework components, turbocharger gatherings, and brake frameworks. The bushings' self-lubricating properties and wear resistance contribute to moved forward vehicle execution and life span.

Chemical Processing

In chemical processing plants, where corrosive substances and high temperatures are common, Teflon lined bushings prove invaluable. They are used in pumps, valves, and agitators, where their chemical resistance and ability to operate without external lubrication enhance equipment reliability and reduce maintenance downtime.

Food Processing

The food industry frequently incorporates high-temperature shapes combined with strict cleanliness necessities. Teflon lined bushings, with their non-stick properties and capacity to withstand steam cleaning, are idealize for utilize in broilers, transport systems, and bundling device.

Renewable Energy

In the creating renewable essentialness division, Teflon lined bushings find applications in sun arranged warm control plants and geothermal imperativeness systems. Their capacity to work beneficially at tall temperatures contributes to the in common execution and immovable quality of these attainable essentialness courses of action.

The versatility of Teflon lined bushings extends to many other industries, including textile manufacturing, paper production, and metalworking. Their unique combination of high-temperature resistance, low friction, and durability makes them a preferred choice for engineers and designers tackling challenging industrial applications.

Conclusion

Teflon lined bushings represent a significant advancement in bearing technology, particularly for high-temperature applications. Their unique three-layer structure, combining the strength of steel, the lubricating properties of porous bronze, and the low-friction characteristics of PTFE, results in a component that excels in challenging environments. From their exceptional temperature resistance and self-lubricating properties to their impressive load capacity and chemical inertness, these bushings offer a host of advantages that make them indispensable across various industries.

As we continue to push the boundaries of industrial processes and machine performance, the role of Teflon lined bushings in high-temperature applications is likely to grow. Their ability to enhance efficiency, reduce maintenance needs, and extend equipment life makes them a smart choice for engineers and designers looking to optimize their high-temperature operations.

For more information about our range of Teflon lined bushings and how they can benefit your specific application, please don't hesitate to contact us at info@wingold.cc. Our team of experts is ready to help you find the perfect bearing solution for your high-temperature challenges.