Understanding the Unique Properties of Large Teflon Washers

The Composition and Structure of Teflon Washers

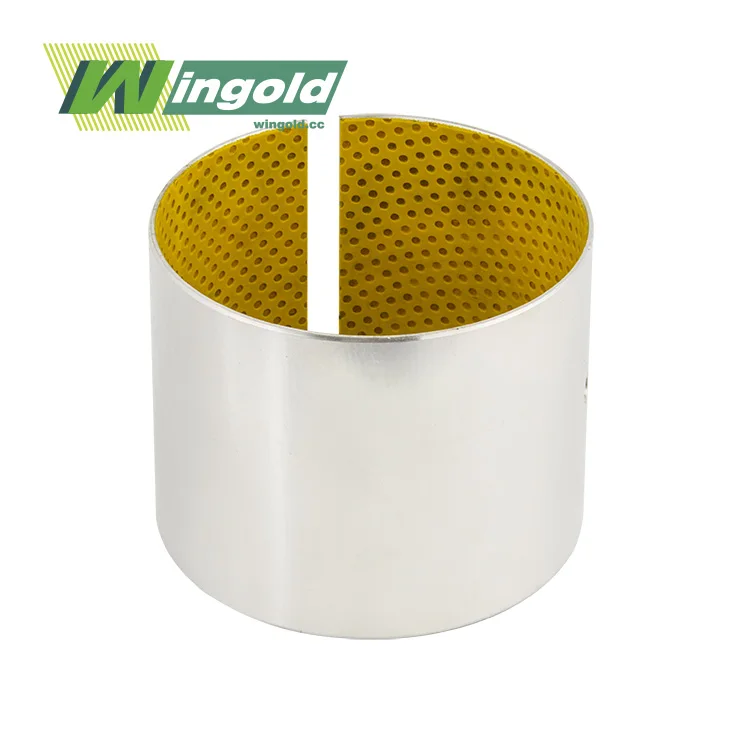

Large Teflon washers are engineered marvels, crafted from high-grade polytetrafluoroethylene (PTFE), commonly known as Teflon. This material's molecular structure grants it remarkable properties that set it apart in the world of sealing solutions. The washers often feature a layered construction, incorporating a steel back for structural integrity and positioning, a porous bronze layer for enhanced friction reduction, and a PTFE layer that provides wear resistance and self-lubrication.

The PTFE layer is the star of the show, offering a unique combination of properties. Its molecular structure consists of carbon atoms surrounded by fluorine atoms, creating a strong, stable bond that resists chemical attack and provides exceptional non-stick properties. This structure also contributes to the material's low coefficient of friction, making it ideal for applications where smooth movement is crucial.

Size Matters: The Advantages of Large Teflon Washers

The "large" in large Teflon washers isn't just a descriptor; it's a key feature that amplifies their effectiveness. These washers, ranging from 50mm to 500mm in diameter, offer several advantages over their smaller counterparts:

- Improved Load Distribution: The larger surface area allows for better distribution of pressure, reducing the likelihood of localized stress and potential failure points.

- Enhanced Sealing Capability: A larger sealing surface can accommodate greater variances in mating surfaces, ensuring a more reliable seal even in challenging conditions.

- Increased Durability: The additional material in larger washers often translates to longer service life, particularly in high-wear applications.

- Versatility in Design: The larger size allows for more complex designs, including custom grooves or patterns that can further enhance sealing performance.

Chemical Resistance and Temperature Tolerance

One of the most impressive attributes of large Teflon washers is their chemical inertness. They resist attack from a vast array of chemicals, including strong acids, bases, and solvents. This property makes them indispensable in chemical processing plants, where exposure to corrosive substances is common.

Moreover, these washers maintain their properties across an extensive temperature range, from cryogenic temperatures as low as -240°C to scorching highs of 260°C. This thermal stability ensures consistent performance in environments where temperature fluctuations are frequent, such as in aerospace applications or industrial ovens.

Applications and Industries Benefiting from Large Teflon Washers

Heavy Machinery and Equipment

In the realm of heavy machinery, large Teflon washers find extensive use. They're particularly valuable in hydraulic and pneumatic systems, where their low friction properties contribute to energy efficiency and smooth operation. In forging and pressing machine tools, these washers help manage the extreme forces involved, providing a reliable seal that can withstand high pressures and temperatures.

The automotive and aerospace industries also leverage the benefits of large Teflon washers. In vehicles, they're used in transmission systems and suspension components, where their self-lubricating properties reduce maintenance requirements. In aircraft, these washers play a crucial role in sealing fuel systems and hydraulic lines, where their chemical resistance and temperature tolerance are paramount.

Chemical Processing and Pharmaceutical Industries

The chemical inertness of large Teflon washers makes them indispensable in chemical processing plants. They're used in pump seals, valve seats, and reactor vessels, where exposure to corrosive chemicals is a constant concern. In the pharmaceutical industry, these washers are prized for their non-reactive nature, ensuring the purity of drug formulations and preventing contamination in production processes.

Food and Beverage Processing

Large Teflon washers have found a niche in food and beverage processing equipment. Their non-stick properties prevent food particles from adhering to surfaces, reducing the risk of contamination and simplifying cleaning processes. Moreover, their compliance with FDA regulations for food-grade materials makes them a safe choice for applications where food contact is possible.

Considerations and Best Practices for Using Large Teflon Washers

Proper Sizing and Installation

While large Teflon washers offer numerous advantages, their effectiveness hinges on proper sizing and installation. It's crucial to select washers that match the specific dimensions and load requirements of your application. Oversized washers may not seat properly, while undersized ones might fail to provide adequate sealing.

During installation, care must be taken to avoid over-tightening, which can deform the washer and compromise its sealing ability. Equally important is ensuring that mating surfaces are clean and free from debris, as even small particles can interfere with the seal.

Maintenance and Inspection

In spite of the fact that Teflon washers are known for their toughness, customary assessment is still fitting, especially in basic applications. See for signs of wear, misshapening, or chemical assault. In high-temperature applications, be mindful that PTFE can involvement "cold stream" over time, possibly influencing the seal's astuteness.

Limitations and Alternatives

In spite of their flexibility, expansive Teflon washers are not a one-size-fits-all arrangement. In applications including certain fluorinated compounds or antacid metals, PTFE can debase. Furthermore, in scenarios where extraordinary compressive quality is required, elective materials like metal or composite washers might be more appropriate.

It's also worth noting that while Teflon washers excel in many areas, they may not be the most cost-effective option for all applications. In some cases, traditional elastomeric seals or newer composite materials might offer a better balance of performance and economy.

Conclusion

Large Teflon washers have undoubtedly revolutionized sealing solutions across numerous industries. Their unique combination of chemical resistance, low friction, and temperature tolerance makes them invaluable in applications ranging from heavy machinery to food processing. While they may not be the universal answer to all sealing challenges, their role in achieving robust, reliable seals in demanding environments is undeniable.

As technology advances and industrial processes become increasingly complex, the importance of high-performance sealing solutions like large Teflon washers is likely to grow. By understanding their properties, applications, and best practices for use, engineers and designers can leverage these remarkable components to enhance the efficiency, reliability, and longevity of their systems. For more information about large Teflon washers and how they can benefit your specific application, please contact us at info@wingold.cc.