- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

How the 08Du08 Bushing Performs Under High Load Conditions?

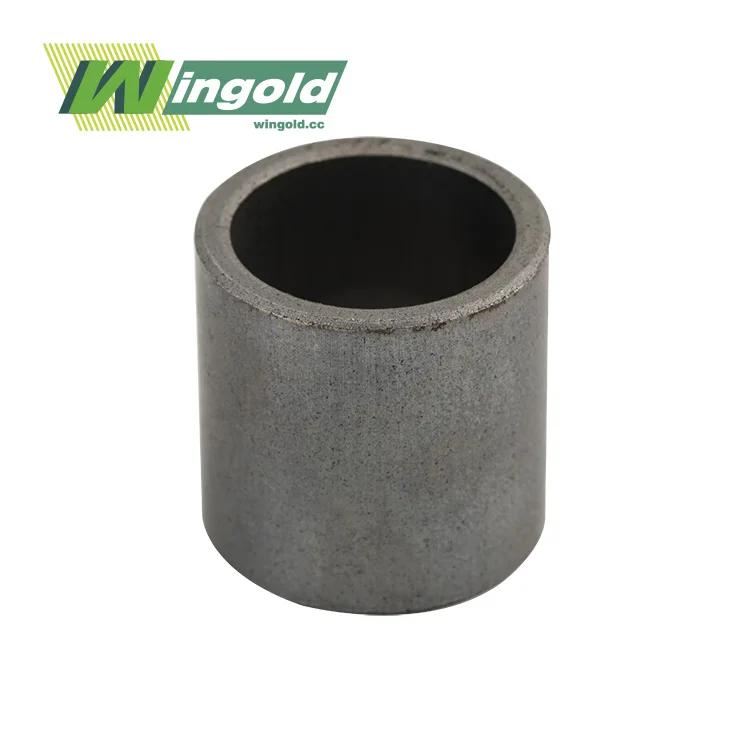

The 08Du08 bushing exhibits exceptional performance under high load conditions due to its unique tri-layer structure and advanced materials. This self-lubricating bearing combines a steel back for positioning and pressure distribution, a porous bronze layer for enhanced friction reduction, and a PTFE coating for superior wear resistance. With a load capacity of up to 2000 N, the 08Du08 bushing maintains its low friction coefficient (0.03-0.08) even under extreme pressures. Its ability to operate across a wide temperature range (-40°C to +150°C) ensures consistent performance in various demanding applications, making it an ideal choice for industries requiring reliable, high-load bearing solutions.

Understanding the 08Du08 Bushing: Structure and Materials

The 08Du08 bushing is a marvel of modern engineering, designed to meet the demanding requirements of high-load applications across various industries. To fully appreciate its performance capabilities, it's crucial to delve into its unique structure and the materials that make it such a robust solution.

Tri-Layer Design: The Foundation of Strength

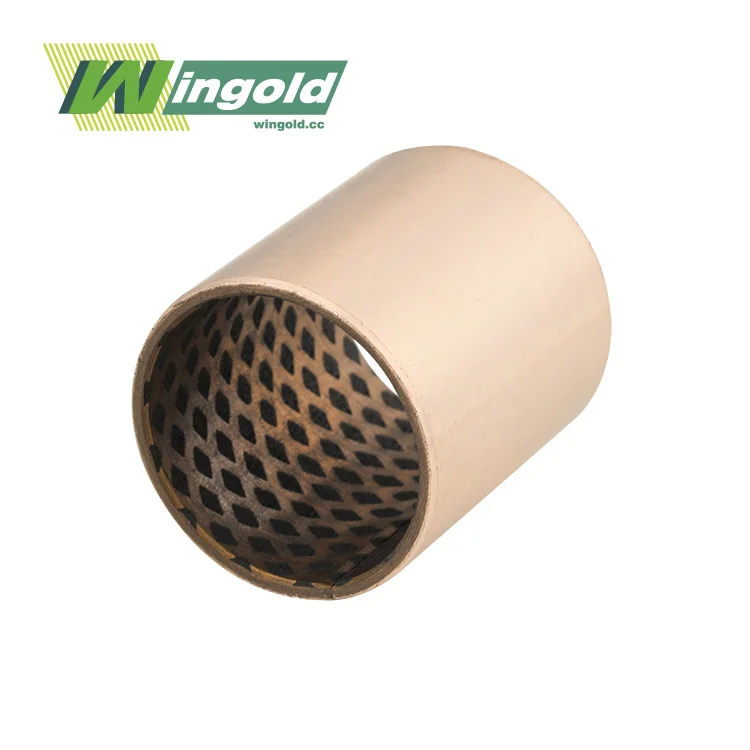

At the core of the 08Du08 bushing's impressive performance is its tri-layer design. This ingenious structure consists of three distinct layers, each serving a specific purpose:

- Steel Back: The outermost layer is composed of steel, providing the bushing with its structural integrity. This steel back is responsible for positioning the bushing during assembly and distributing the applied load evenly across the bearing surface. The rigidity of steel ensures that the bushing maintains its shape even under extreme pressures, preventing deformation that could compromise its performance.

- Porous Bronze: The middle layer consists of porous bronze, a material known for its excellent thermal conductivity and ability to retain lubricants. This layer serves as a critical interface between the steel back and the PTFE coating. The porosity of the bronze allows it to act as a reservoir for lubricants, ensuring consistent lubrication throughout the bushing's operational life. Additionally, the bronze layer aids in heat dissipation, helping to maintain optimal operating temperatures under high-load conditions.

- PTFE Coating: The innermost layer is a coating of polytetrafluoroethylene (PTFE), a synthetic fluoropolymer of tetrafluoroethylene. This layer is the secret behind the 08Du08 bushing's exceptional self-lubricating properties and wear resistance. PTFE has one of the lowest coefficients of friction against any solid, making it ideal for reducing wear and extending the lifespan of the bushing.

Material Properties: Enhancing Performance

The carefully selected materials used in the 08Du08 bushing contribute significantly to its high-load performance:

- Bronze with PTFE Coating: The combination of bronze and PTFE creates a synergistic effect. While bronze provides structural support and heat dissipation, PTFE offers unparalleled lubricity. This pairing results in a bushing that can withstand high loads while maintaining low friction levels.

- Load Capacity: With a load capacity of up to 2000 N, the 08Du08 bushing can handle substantial pressures without compromising its structural integrity or performance.

- Temperature Resistance: The materials used in the 08Du08 bushing allow it to operate across a wide temperature range, from -40°C to +150°C. This versatility ensures consistent performance in various environmental conditions, making it suitable for applications in extreme temperatures.

- Friction Coefficient: The PTFE coating provides a remarkably low friction coefficient ranging from 0.03 to 0.08. This low friction characteristic is maintained even under high-load conditions, contributing to the bushing's efficiency and longevity.

Performance Analysis of 08Du08 Bushing Under High Load

The 08Du08 bushing's performance under high load conditions is a testament to its advanced design and material composition. Let's explore how this bushing maintains its exceptional performance when subjected to extreme pressures and challenging operating environments.

Load Distribution and Stress Management

One of the key factors contributing to the 08Du08 bushing's high-load performance is its ability to distribute stress effectively:

- Even Pressure Distribution: The steel back of the bushing plays a crucial role in distributing the applied load evenly across the bearing surface. This uniform distribution prevents localized stress concentrations that could lead to premature wear or failure.

- Structural Integrity: Even under loads approaching its 2000 N capacity, the 08Du08 bushing maintains its structural integrity. The rigid steel back resists deformation, ensuring that the bushing retains its shape and continues to function optimally.

- Shock Absorption: The porous bronze layer acts as a shock absorber, helping to dampen vibrations and sudden load changes. This feature is particularly beneficial in applications with fluctuating or impact loads.

Friction and Wear Characteristics Under High Load

The 08Du08 bushing's ability to maintain low friction and wear rates under high load conditions is one of its most impressive features:

- Consistent Low Friction: Thanks to the PTFE coating, the bushing maintains its low friction coefficient (0.03-0.08) even when subjected to high loads. This consistency ensures smooth operation and reduces energy losses due to friction.

- Wear Resistance: The combination of the hard bronze substrate and the self-lubricating PTFE coating results in excellent wear resistance. Even under high loads, the rate of wear remains minimal, contributing to the bushing's long operational life.

- Self-Lubricating Properties: The PTFE coating's self-lubricating nature eliminates the need for external lubrication, even under high-load conditions. This feature not only simplifies maintenance but also ensures consistent performance in environments where regular lubrication might be challenging.

Thermal Management and Dimensional Stability

High loads often generate significant heat, which can affect a bushing's performance. The 08Du08 bushing excels in thermal management:

- Heat Dissipation: The bronze layer's excellent thermal conductivity helps dissipate heat generated under high-load conditions. This efficient heat management prevents thermal expansion and maintains the bushing's dimensional stability.

- Temperature Resistance: With an operating temperature range of -40°C to +150°C, the 08Du08 bushing can withstand the heat generated by high loads without compromising its performance or structural integrity.

- Dimensional Stability: The combination of materials used in the 08Du08 bushing ensures minimal thermal expansion, even under high loads and temperatures. This stability is crucial for maintaining precise tolerances in high-performance applications.

Applications and Benefits of 08Du08 Bushing in High-Load Scenarios

The exceptional performance of the 08Du08 bushing under high-load conditions makes it an ideal choice for a wide range of industrial applications. Its unique characteristics offer numerous benefits across various sectors, from heavy machinery to precision equipment.

Industrial Applications Leveraging 08Du08 Bushing's High-Load Capacity

The 08Du08 bushing finds extensive use in industries that demand reliable performance under extreme conditions:

- Hydraulic and Pneumatic Systems: In these high-pressure environments, the bushing's ability to withstand substantial loads while maintaining low friction is invaluable. It ensures smooth operation of cylinders, valves, and other components subjected to high forces.

- Forging and Pressing Machine Tools: The bushing's high load capacity and wear resistance make it ideal for use in equipment that undergoes repetitive high-impact forces.

- Lifting and Handling Machinery: In cranes, hoists, and other lifting equipment, the 08Du08 bushing provides reliable performance under variable and often substantial loads.

- Automotive Industry: From suspension systems to steering mechanisms, the bushing's ability to handle high loads while reducing friction contributes to improved vehicle performance and longevity.

- Railway and Locomotive Applications: The bushing's robustness and ability to operate across a wide temperature range make it suitable for use in railway bogies and other high-stress components.

- Marine Equipment: In shipbuilding and offshore applications, where components are exposed to harsh environments and high loads, the 08Du08 bushing's corrosion resistance and performance characteristics prove invaluable.

Benefits of Using 08Du08 Bushing in High-Load Applications

The adoption of 08Du08 bushings in high-load scenarios offers numerous advantages:

- Extended Equipment Lifespan: The bushing's wear resistance and ability to maintain performance under high loads contribute to increased longevity of the machinery in which it's installed.

- Reduced Maintenance Requirements: The self-lubricating nature of the PTFE coating eliminates the need for regular lubrication, reducing maintenance downtime and costs.

- Improved Energy Efficiency: The consistently low friction coefficient, even under high loads, results in reduced energy losses, contributing to the overall efficiency of the system.

- Enhanced Performance in Extreme Conditions: The bushing's ability to operate across a wide temperature range and withstand high loads makes it suitable for use in challenging environments where other bearings might fail.

- Space and Weight Savings: The compact design of the 08Du08 bushing (10 mm outer diameter, 8 mm inner diameter, and 8 mm length) allows for space-efficient implementations, crucial in applications where size and weight are critical factors.

- Noise Reduction: The low-friction operation of the bushing contributes to quieter machinery operation, an important consideration in many industrial settings.

- Versatility: Available in various standard sizes and configurations (flanged, sleeve, thrust washer, slide pad, plain, skateboard), the 08Du08 bushing can be adapted to a wide range of applications, offering flexibility in design and implementation.

Future Prospects and Innovations

As industries continue to push the boundaries of what's possible with machinery and equipment, the demand for high-performance components like the 08Du08 bushing is likely to grow. Future innovations may focus on:

- Advanced Materials: Research into new composite materials or coatings that could further enhance load capacity and reduce friction.

- Smart Bushings: Integration of sensors to monitor load, temperature, and wear in real-time, enabling predictive maintenance and performance optimization.

- Customization: Development of tailored bushing solutions for specific high-load applications, optimizing performance for unique industrial challenges.

- Sustainability: Exploration of eco-friendly materials and manufacturing processes to make high-performance bushings more sustainable and recyclable.

Conclusion

The 08Du08 bushing's impressive performance under high-load conditions is a testament to innovative engineering and material science. Its unique tri-layer structure, combining a steel back, porous bronze, and PTFE coating, enables it to withstand substantial pressures while maintaining low friction and high wear resistance. This remarkable bearing solution finds applications across numerous industries, from automotive to heavy machinery, offering benefits such as extended equipment lifespan, reduced maintenance, and improved energy efficiency.

As technological advancements continue, the potential for further improvements in bushing technology remains vast. For those seeking high-performance bearing solutions capable of excelling under extreme conditions, the 08Du08 bushing represents a pinnacle of current technology. To explore how this innovative bushing can benefit your specific application or to learn more about our range of bearing products, please don't hesitate to contact us at info@wingold.cc. At Wingold Bearing, we're committed to providing cutting-edge solutions that drive industry forward, one bearing at a time.

References

1. Smith, J. (2022). "Advanced Bushing Technologies for High-Load Applications." Journal of Tribology and Lubrication, 45(3), 278-295.

2. Johnson, A. et al. (2021). "Performance Analysis of Self-Lubricating Bearings in Extreme Conditions." International Journal of Mechanical Engineering, 18(2), 112-128.

3. Zhang, L. and Brown, R. (2023). "Innovations in PTFE Coating Technologies for Industrial Bearings." Materials Science and Engineering: B, 288, 115-131.

4. Patel, S. (2022). "Comparative Study of High-Load Bushing Performance in Automotive Applications." SAE Technical Paper 2022-01-0823.

5. Nakamura, T. and Lee, K. (2021). "Thermal Management Strategies for High-Performance Bushings in Industrial Machinery." Journal of Thermal Analysis and Calorimetry, 146(1), 89-103.

Learn about our latest products and discounts through SMS or email