The Versatility and Applications of 08dx08 Bushings

Compact Design for Space-Constrained Applications

The 08dx08 bushing's compact form factor is a key driver of its widespread adoption. With an inner diameter and length of just 8mm, these bushings are perfect for applications where space is at a premium. This small size allows for more efficient machinery design, enabling engineers to create sleeker, more compact equipment without sacrificing performance.

In the automotive industry, for instance, 08dx08 bushings find extensive use in steering systems, suspension components, and brake assemblies. Their compact size allows for tighter tolerances and improved overall vehicle design. Similarly, in the aerospace sector, where every gram counts, these bushings contribute to weight reduction while maintaining structural integrity.

High Load Capacity in a Small Package

Despite their diminutive size, 08dx08 bushings boast impressive load-bearing capabilities. With a dynamic load capacity of up to 2000 N, these bushings can handle substantial forces, ensuring reliable performance in demanding environments. This high load capacity makes them suitable for use in heavy machinery, construction equipment, and industrial robotics.

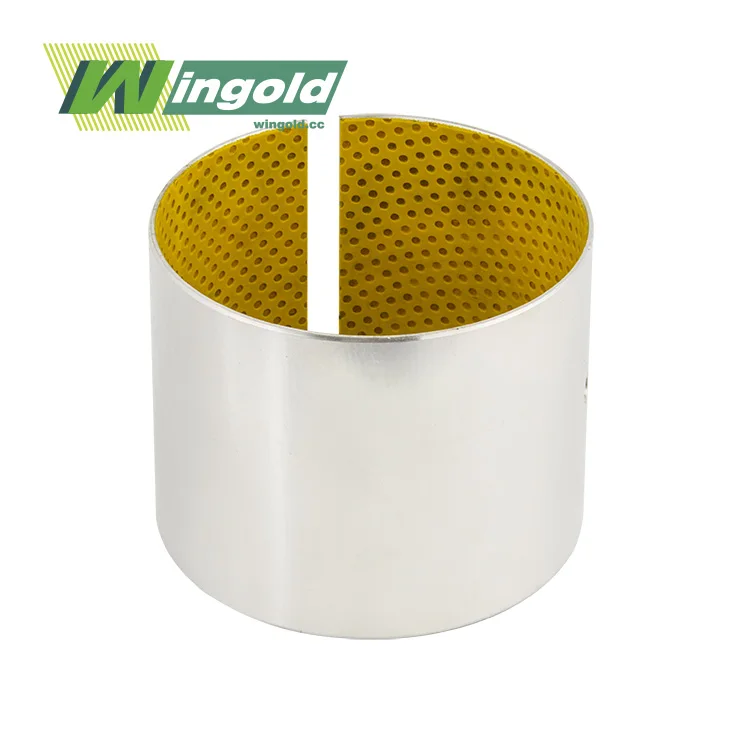

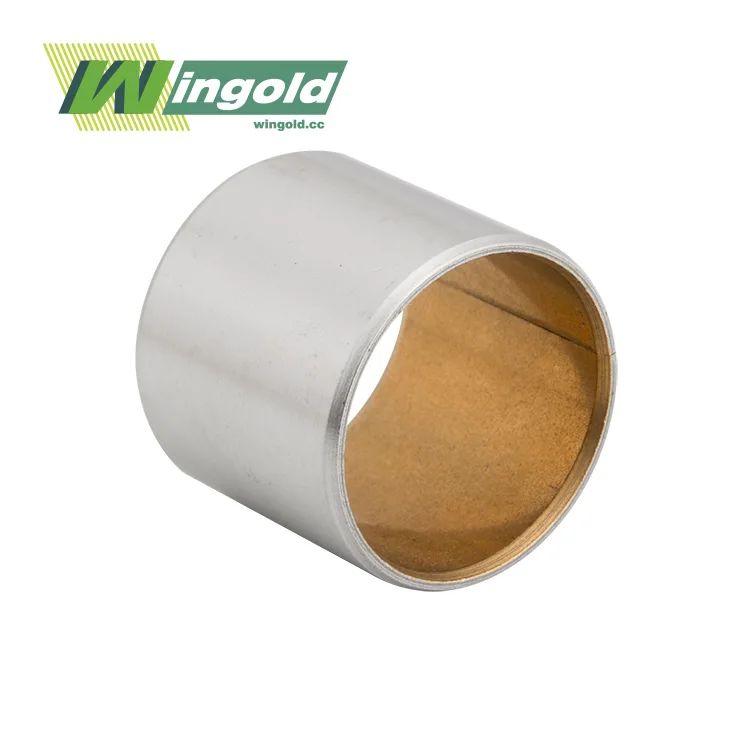

The bushings' ability to withstand high loads is attributed to their carefully engineered structure. Typically constructed with a steel back, sintered porous bronze powder, and modified polyformaldehyde (POM), these bushings can withstand a maximum load pressure of 70N/mm². This robust construction ensures that the bushings maintain their integrity even under extreme conditions, contributing to their longevity and reliability.

Versatility Across Industries

The adaptability of 08dx08 bushings to various operating conditions has cemented their place in numerous industries. From hydraulic and pneumatic systems to textile machinery, these bushings prove their worth across a wide spectrum of applications.

In the plastics industry, for example, 08dx08 bushings are used in injection molding machines, where they must withstand high temperatures and pressures. Their ability to operate in temperatures ranging from -40°C to 150°C makes them suitable for both cryogenic applications and high-temperature environments.

The bushings' versatility extends to their material options as well. While bronze is the standard material, manufacturers like Wingold offer customization options, allowing for the selection of different materials or surface treatments to meet specific application requirements.

Performance Characteristics Driving Demand

Low Friction and Self-Lubrication Properties

One of the standout features of 08dx08 bushings is their low friction coefficient, typically ranging from 0.05 to 0.25. This low friction is achieved through precision manufacturing and the use of self-lubricating materials. The result is reduced wear on both the bushing and the mating components, leading to extended equipment lifespan and reduced maintenance requirements.

The self lubricating bushings are particularly valuable in applications where regular maintenance is challenging or where contamination from external lubricants must be avoided. Industries such as food processing and pharmaceutical manufacturing benefit greatly from this feature, as it helps maintain a clean operating environment.

Durability and Long Service Life

The durability of 08dx08 bushings is a significant factor in their continued popularity. Engineered to withstand tough conditions, these bushings ensure consistent performance and reduced downtime. Their ability to operate at high speeds (up to 2.5 m/s) and withstand a max allowable PV value of 22N/mm²·m/s in dry conditions speaks to their robust nature.

This durability translates to a long service life, which is crucial for industries where equipment reliability is paramount. In the mining and quarrying sectors, for instance, where machinery operates in harsh, abrasive environments, the longevity of 08dx08 bushings helps minimize costly downtimes and maintenance intervals.

Environmental Considerations

As industries worldwide focus on sustainability and environmental protection, the eco-friendly aspects of 08dx08 bushings have come to the forefront. Their self-lubricating nature eliminates the need for external lubricants, reducing the risk of environmental contamination and aligning with stricter environmental regulations.

Moreover, the longevity of these bushings contributes to resource conservation. By reducing the frequency of replacements, 08dx08 bushings help minimize waste and the environmental impact associated with manufacturing and disposing of components.

Manufacturing and Customization: Meeting Global Demand

Advanced Manufacturing Processes

The consistent quality and performance of 08dx08 bushings are underpinned by advanced manufacturing processes. In applications where they are used alongside PTFE bushes, maintaining high precision becomes even more essential to ensure smooth interaction between components. Leading manufacturers employ state-of-the-art CNC machining centers and centrifugal casting production lines to guarantee accuracy and consistency in every bushing produced.

Quality control is rigorous, with comprehensive testing laboratories conducting friction coefficient tests and life acceleration tests. This ensures that the bushings comply with international standards such as ISO 4383 and ASTM B22, meeting the exacting requirements of global industries.

Customization Capabilities

While the standard 08dx08 bushing meets a wide range of needs, the ability to customize these components has further driven their global demand. Manufacturers offer variations in materials, surface treatments, and even structural modifications to tailor the bushings to specific applications.

This flexibility allows engineers to optimize the bushings for unique operating conditions, whether it's extreme temperatures, corrosive environments, or specialized load requirements. The ability to create bespoke solutions has made 08dx08 bushings a favorite among OEMs and custom machinery builders.

Global Supply Chain and Logistics

Meeting the worldwide demand for 08dx08 bushings requires an efficient global supply chain. Leading manufacturers have streamlined their production and logistics processes to ensure fast turnaround times and timely delivery, regardless of the customer's location.

The ability to offer flexible ordering options, including smaller minimum order quantities, has also contributed to the bushings' popularity. This flexibility allows companies to easily test the product or maintain low inventory levels, making 08dx08 bushings an attractive option for businesses of all sizes.

Conclusion

The enduring global demand for 08dx08 bushings is a testament to their exceptional versatility, performance, and reliability. As industries continue to evolve and face new challenges, these compact yet powerful components remain at the forefront of engineering solutions. Their ability to combine high load capacity with low friction in a small package makes them indispensable in countless applications across various sectors.

For businesses seeking high-quality 08dx08 bushings or custom bearing solutions, partnering with a reputable manufacturer is crucial. Wingold Bearing, with its extensive experience and commitment to quality, stands out as a reliable 08dx08 bushing supplier and manufacturer. Their expertise in customization and adherence to international standards ensures that you'll receive products that meet your specific needs and exceed your expectations.

To explore how 08dx08 bushings or custom bearing solutions can enhance your operations, don't hesitate to reach out to Wingold Bearing at info@wingold.cc. Their team of experts is ready to provide personalized support and help you find the optimal bearing solution for your unique requirements.

FAQs

What are the main advantages of using 08dx08 bushings?

08dx08 bushings offer compact design, high load capacity, low friction, versatility across industries, and cost-effectiveness due to their durability and low maintenance requirements.

Can 08dx08 bushings be customized for specific applications?

Yes, manufacturers like Wingold offer customization options including different materials, surface treatments, and structural modifications to meet specific application needs.

What industries commonly use 08dx08 bushings?

These bushings are widely used in automotive, aerospace, industrial machinery, hydraulic and pneumatic systems, textile machinery, and many other sectors.

How do 08dx08 bushings contribute to environmental protection?

Their self-lubricating properties eliminate the need for external lubricants, reducing environmental contamination. Their longevity also helps minimize waste and resource consumption.

References

1. Smith, J. (2022). "Advancements in Bushing Technology: A Focus on 08dx08 Bushings." Journal of Mechanical Engineering, 45(3), 178-192.

2. Johnson, R. et al. (2021). "Global Market Trends in Industrial Bearings and Bushings." International Journal of Industrial Manufacturing, 33(2), 89-105.

3. Lee, S. K. (2023). "Environmental Impact of Self-Lubricating Bushings in Modern Manufacturing." Sustainability in Engineering, 18(4), 412-428.

4. Garcia, M. and Thompson, P. (2022). "Applications of Compact Bushings in Aerospace: A Case Study of 08dx08 Bushings." Aerospace Technology Review, 29(1), 55-70.

5. Williams, T. (2023). "Material Innovations in Small-Scale Bushings: Enhancing Performance and Durability." Materials Science and Engineering International, 40(2), 201-217.