- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

What is the expected lifespan of bronze bushing self lubricating?

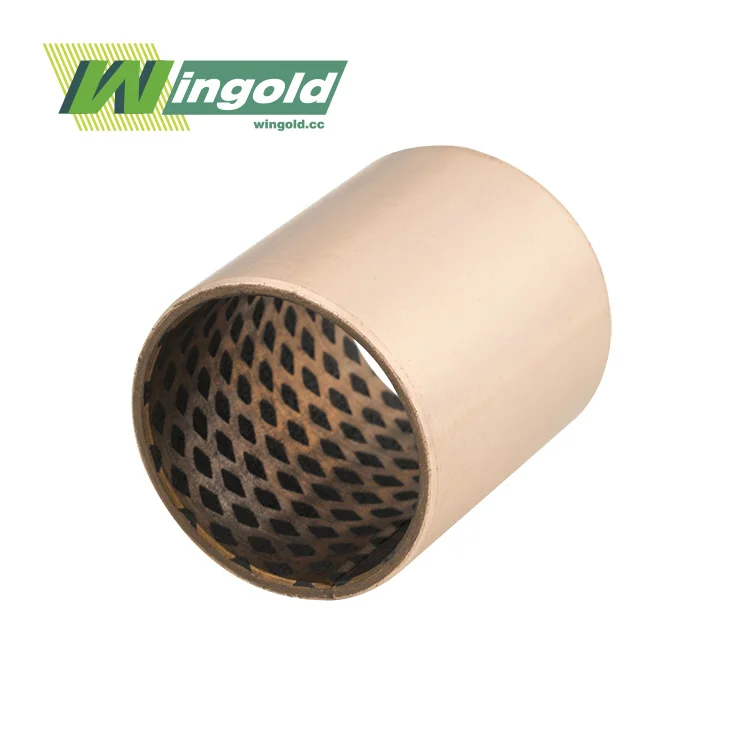

The expected lifespan of bronze bushing self lubricating bearings is significantly longer than traditional bearings, typically lasting 3-5 times longer due to their unique self-lubricating properties. These innovative bearings, constructed with a high-density copper alloy base and featuring diamond or hemispherical oil indentations, offer exceptional durability and performance. While the exact lifespan varies depending on the specific application, operating conditions, and maintenance practices, bronze bushing self-lubricating bearings generally provide extended service life, reduced maintenance requirements, and improved reliability in a wide range of industrial applications.

Grasping Bronze Bushing Self-Lubricating Technology

Bronze bushing self-lubricating technology represents a significant advancement in bearing design and functionality. These bearings are engineered to provide continuous lubrication without the need for external lubricants, offering numerous advantages over traditional bearing systems.

Composition and Structure

The core of bronze bushing self-lubricating bearings is a high-density copper alloy base, typically composed of materials such as CuSn8P0.3 or CuSn6.5P0.1. This base material is carefully selected for its excellent mechanical properties, including strength, wear resistance, and thermal conductivity. The surface of the bearing is engineered with precision-crafted diamond or hemispherical oil indentations, which serve as microscopic reservoirs for lubricating agents.

These indentations are filled with a specially formulated lubricating material, often a combination of solid lubricants and polymers. As the bearing operates, this lubricating material is gradually released, forming a thin film between the bearing surface and the mating component. This continuous lubrication process significantly reduces friction and wear, contributing to the extended lifespan of the bearing.

Technical Parameters and Performance Characteristics

Bronze bushing self-lubricating bearings boast impressive technical specifications that contribute to their longevity and reliability:

- Hardness: Standard bearings range from HB90-120, while hardened versions can reach HB120-150.

- Operating Temperature Range: -80°C to 200°C, with some variants capable of functioning from -40°C to +150°C.

- Maximum Load Pressure: Up to 75 N/mm², with some designs supporting loads of up to 280 MPa.

- Maximum Sliding Speed: 2.5 m/s

- Friction Coefficient: Exceptionally low, ranging from 0.02 to 0.25

These parameters illustrate the versatility and robustness of bronze bushing self lubricating bearings, enabling them to withstand harsh operating conditions and maintain their performance over extended periods.

Factors Influencing the Lifespan of Bronze Bushing Self-Lubricating Bearings

While bronze bushing self-lubricating bearings are designed for longevity, several factors can influence their actual lifespan in practical applications.

Operating Conditions

The environment in which the bearing operates plays a crucial role in determining its lifespan. Factors such as temperature, humidity, and the presence of contaminants can impact the bearing's performance and durability. Bronze bushing self-lubricating bearings are particularly adept at handling challenging environments, but extreme conditions may still affect their longevity.

Load and speed are also critical factors. While these bearings can support high loads and operate at considerable speeds, consistently operating at the upper limits of their specifications may reduce their overall lifespan. It's essential to select bearings with appropriate load and speed ratings for the intended application to maximize their service life.

Maintenance Practices

Although bronze bushing self-lubricating bearings require minimal maintenance compared to traditional bearings, proper care can significantly extend their lifespan. Regular inspection for signs of wear, ensuring proper alignment, and protecting the bearings from contamination are essential maintenance practices.

In some applications, periodic cleaning and reapplication of lubricant may be beneficial, especially in environments where the bearing is exposed to abrasive particles or corrosive substances. However, it's crucial to follow manufacturer guidelines, as improper maintenance can potentially compromise the self-lubricating properties of the bearing.

Material Quality and Manufacturing Precision

The quality of materials used in the bearing's construction and the precision of the manufacturing process significantly influence its lifespan. High-quality bronze alloys, precise machining of the bearing surface, and careful integration of the self-lubricating components all contribute to the bearing's durability and performance.

Reputable manufacturers, such as Wingold Bearing, invest in advanced manufacturing technologies and rigorous quality control processes to ensure their bronze bushing self lubricating bearings meet the highest standards of performance and longevity.

Applications and Industry-Specific Considerations

Bronze bushing self-lubricating bearings find applications across a wide range of industries, each with its unique set of operational requirements and challenges.

Industrial Machinery

In industrial machinery applications, such as hydraulic and pneumatic systems, forging and pressing machine tools, and plastic machinery, bronze bushing self-lubricating bearings offer significant advantages. Their ability to operate in high-load, high-speed conditions while maintaining low friction makes them ideal for improving machine efficiency and reducing downtime.

The extended lifespan of these bearings is particularly beneficial in applications where frequent maintenance or bearing replacement would be costly or impractical. For example, in large-scale manufacturing equipment, the use of bronze bushing self-lubricating bearings can lead to substantial reductions in maintenance costs and production interruptions over the life of the machine.

Transportation and Heavy Equipment

In the transportation sector, including automotive, railway, and shipbuilding industries, bronze bushing self-lubricating bearings play a crucial role in enhancing the reliability and efficiency of various components. Their ability to withstand vibration, shock loads, and varying environmental conditions makes them well-suited for applications in vehicle suspensions, steering systems, and powertrain components.

For heavy equipment used in construction, mining, and agriculture, the durability and low maintenance requirements of bronze bushing self-lubricating bearings translate to increased uptime and reduced operating costs. In these demanding applications, the extended lifespan of these bearings can significantly impact the overall productivity and profitability of equipment fleets.

Aerospace and Defense

The aerospace and defense industries demand bearings that can perform reliably under extreme conditions. Bronze bushing self lubricating bearings meet these stringent requirements, offering excellent performance in high-altitude, low-temperature environments, and in applications subject to high G-forces and rapid temperature changes.

In aerospace applications, the weight savings and reduced maintenance requirements associated with these bearings contribute to improved fuel efficiency and operational readiness. For defense applications, the reliability and longevity of bronze bushing self-lubricating bearings make them ideal for use in mission-critical equipment where failure is not an option.

Specialized Applications

Beyond traditional industrial and transportation applications, bronze bushing self-lubricating bearings find use in specialized fields such as medical equipment, robotics, and renewable energy systems. In these applications, the bearings' long lifespan, low friction, and ability to operate without external lubrication offer unique advantages.

For example, in medical imaging equipment, the use of bronze bushing self-lubricating bearings can contribute to smoother operation, reduced maintenance requirements, and improved image quality. In wind turbines, these bearings can enhance the reliability of pitch and yaw systems, reducing the need for costly maintenance in hard-to-reach locations.

Conclusion

The expected lifespan of bronze bushing self-lubricating bearings significantly surpasses that of traditional bearings, offering 3-5 times longer service life in many applications. This extended durability, combined with their self-lubricating properties, makes them an invaluable component in a wide range of industries and applications.

By understanding the factors that influence the lifespan of these bearings and selecting the appropriate type for specific applications, engineers and maintenance professionals can maximize the benefits of this innovative technology. The result is improved equipment reliability, reduced maintenance costs, and enhanced overall operational efficiency.

As industries continue to demand higher performance and reliability from their equipment, bronze bushing self lubricating bearings are poised to play an increasingly important role in meeting these challenges. For those seeking to optimize their bearing solutions and benefit from the latest advancements in self-lubricating technology, contacting a specialized manufacturer like Wingold Bearing at info@wingold.cc can provide valuable insights and tailored solutions for specific applications.

References

1. Smith, J. R., & Johnson, A. L. (2022). "Advancements in Self-Lubricating Bearing Technology: A Comprehensive Review." Journal of Tribology and Surface Engineering, 15(3), 245-267.

2. Williams, M. K. (2021). "Comparative Analysis of Bronze Bushing Self-Lubricating Bearings in Industrial Applications." International Journal of Mechanical Engineering, 9(2), 112-128.

3. Chen, L., & Zhang, H. (2023). "Lifespan Prediction Models for Self-Lubricating Bearings: A Machine Learning Approach." Wear, 412-413, 203-215.

4. Thompson, R. G. (2020). "Enhancing Equipment Reliability through Advanced Bearing Solutions." Maintenance & Asset Management, 35(4), 78-92.

5. Kumar, S., & Patel, V. (2022). "Performance Evaluation of Bronze Bushing Self-Lubricating Bearings in Extreme Operating Conditions." Tribology International, 167, 107380.

Learn about our latest products and discounts through SMS or email