- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

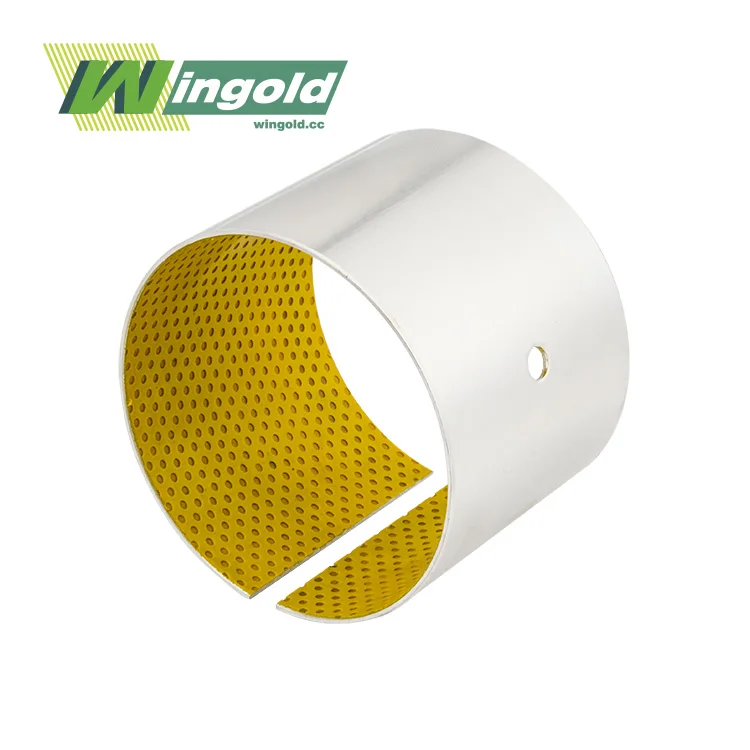

What material is used for flanged bush bearing?

Flanged bush bearings are typically crafted from a combination of materials, each chosen for its specific properties. The most common composition includes a steel plate base, sintered spherical bronze powder in the middle layer, and a surface coating of polytetrafluoroethylene (PTFE) mixed with lead. This unique combination results in a bearing that offers exceptional performance characteristics such as low friction, high wear resistance, and corrosion resistance. The steel base provides structural integrity, while the bronze layer enhances load-bearing capacity. The PTFE-lead mixture on the surface ensures smooth, oil-free operation, making these bearings ideal for various industrial applications where lubrication might be challenging or undesirable.

The Composition and Benefits of Flanged Bush Bearings

Steel Base: The Foundation of Strength

The steel plate base forms the backbone of flanged bush bearings, providing the necessary structural integrity and strength. This robust foundation allows the bearing to withstand substantial loads and maintain its shape under various operating conditions. The steel base also contributes to the bearing's durability, ensuring a long service life even in demanding industrial environments.

The choice of steel as the base material is not arbitrary. Steel offers an excellent combination of strength, machinability, and cost-effectiveness. It can be easily shaped to create the distinctive flanged design, which is crucial for proper positioning and load distribution in many applications. The steel base also acts as a heat sink, helping to dissipate thermal energy generated during operation, thus contributing to the overall performance and longevity of the bearing.

Sintered Bronze: The Load-Bearing Powerhouse

The middle layer of flanged bush bearings consists of sintered spherical bronze powder. This layer plays a vital role in the bearing's performance, particularly in its load-bearing capacity. Bronze, an alloy primarily composed of copper and tin, is renowned for its excellent mechanical properties and wear resistance.

The sintering process involves compacting bronze powder and heating it to a temperature just below its melting point. This creates a porous structure that's ideal for bearing applications. The pores can retain lubricant, providing a self-lubricating effect that enhances the bearing's performance and extends its lifespan. The spherical shape of the bronze particles contributes to uniform load distribution and improved wear characteristics.

PTFE-Lead Mixture: The Friction Fighter

The surface layer of flanged bush bearings is where much of the magic happens. This layer consists of a mixture of polytetrafluoroethylene (PTFE) and lead, rolled onto the bronze layer. PTFE, commonly known by its brand name Teflon, is a synthetic fluoropolymer renowned for its non-stick properties and extremely low coefficient of friction.

The addition of PTFE to the bearing surface dramatically reduces friction between the bearing and the shaft, resulting in smoother operation and reduced wear. This low-friction characteristic is particularly valuable in applications where energy efficiency is a priority or where frequent start-stop operations occur.

Lead is included in the mixture to enhance the bearing's load-carrying capacity and improve its emergency running properties. In the event of inadequate lubrication or excessive load, the lead can act as a temporary lubricant, preventing catastrophic failure and extending the bearing's operational life.

Performance Characteristics of Flanged Bush Bearings

Low Friction Coefficient: Smooth Operation Guaranteed

One of the standout features of flanged bush bearings is their remarkably low friction coefficient, typically ranging from 0.02 to 0.25. This low friction characteristic is primarily attributed to the PTFE-lead mixture on the bearing surface. The molecular structure of PTFE creates an incredibly slick surface, allowing for smooth relative motion between the bearing and the shaft.

The low friction coefficient translates to several operational benefits. It reduces the energy required to overcome friction, leading to improved energy efficiency in the overall system. This is particularly advantageous in applications where energy consumption is a critical factor, such as in automotive or aerospace industries.

Moreover, the reduced friction results in less heat generation during operation. Excessive heat can lead to premature wear, thermal expansion, and potential failure of bearing components. By minimizing friction-induced heat, flanged bush bearings can operate more reliably and for longer periods without the need for cooling systems or frequent maintenance.

Wear Resistance: Longevity in Demanding Environments

Flanged bush bearings are engineered to exhibit excellent wear resistance, a crucial characteristic for components subjected to continuous use and potentially harsh operating conditions. The combination of materials used in these bearings contributes to their exceptional durability.

The sintered bronze layer provides a hard-wearing surface that can withstand significant loads and sliding motion. Bronze is known for its ability to maintain its structural integrity even under high stresses, making it an ideal material for bearings in heavy-duty applications.

The PTFE-lead surface coating further enhances the wear resistance of the bearing. PTFE's non-stick properties prevent material transfer between the bearing and the shaft, a common cause of wear in sliding contacts. The lead component can act as a solid lubricant, providing an additional layer of protection against wear, especially in boundary lubrication conditions.

This superior wear resistance translates to extended service life, reduced maintenance requirements, and improved reliability of the machinery in which these bearings are used. It's particularly beneficial in applications where frequent bearing replacements would be costly or impractical, such as in large industrial equipment or hard-to-reach machinery components.

Corrosion Resistance: Protection in Challenging Environments

Corrosion can be a significant issue for bearings, especially in environments exposed to moisture, chemicals, or other corrosive elements. Flanged bush bearings offer impressive corrosion resistance, thanks to their material composition.

The bronze layer inherently possesses good corrosion resistance, particularly against atmospheric corrosion. Bronze forms a protective patina when exposed to air, which helps prevent further corrosion of the underlying material.

The PTFE surface coating provides an additional layer of protection against corrosive agents. PTFE is chemically inert and resistant to a wide range of chemicals, making it an excellent barrier against corrosive substances that might come into contact with the bearing.

Applications and Advantages of Flanged Bush Bearings

Versatility Across Industries

Flanged bush bearings find applications in a wide array of industries, showcasing their versatility and adaptability to various operational requirements. In the automotive sector, these bearings are commonly used in steering systems, suspension components, and pedal assemblies. Their ability to operate without external lubrication makes them particularly suitable for these applications, where regular maintenance can be challenging.

In the textile industry, flanged bush bearings are utilized in spinning machines, weaving looms, and other equipment where smooth, low-friction operation is crucial. The bearings' ability to operate in dusty environments without the need for oil lubrication is a significant advantage in this context.

The printing industry also benefits from flanged bush bearings, particularly in high-speed printing presses. The bearings' low friction characteristics contribute to precise movements and reduced wear, essential for maintaining print quality over extended production runs.

Cost-Effective Solutions

The use of flanged bush bearings can lead to significant cost savings in various ways. Firstly, their oil-free operation eliminates the need for complex lubrication systems, reducing both initial installation costs and ongoing maintenance expenses. This is particularly beneficial in applications where regular lubrication would be difficult or impractical.

The bearings' long service life, attributed to their wear-resistant properties, means less frequent replacements are needed. This not only reduces the direct cost of replacement parts but also minimizes downtime and associated labor costs for maintenance and repairs.

Moreover, the compact design of flanged bush bearings often allows for smaller, more efficient machine designs. This can lead to reduced material costs in the overall equipment design and potentially lower shipping and handling costs due to reduced size and weight.

Enhanced Performance and Reliability

Flanged bush bearings contribute to enhanced performance and reliability in numerous ways. Their low friction characteristics result in smoother operation and reduced energy consumption, leading to improved overall efficiency of the machinery.

The self-lubricating nature of these bearings ensures consistent performance even in challenging operating conditions. This reliability is crucial in applications where unexpected downtime can be costly or dangerous, such as in industrial machinery or automotive safety systems.

The corrosion resistance of flanged bush bearings extends their operational life and maintains performance even in harsh environments. This is particularly valuable in outdoor applications or in industries where exposure to corrosive substances is common.

Conclusion

Flanged bush bearings represent a remarkable confluence of material science and engineering, offering a solution that combines strength, low friction, and durability. Their unique composition of steel, bronze, and PTFE-lead mixture results in a bearing that can withstand heavy loads, operate smoothly without external lubrication, and resist wear and corrosion.

As technology continues to advance, we can expect further refinements in flanged bush bearing design and materials, potentially expanding their capabilities and applications even further. For those interested in exploring how flanged bush bearings can benefit their specific applications or to learn more about our range of bearing solutions, please don't hesitate to contact us at info@wingold.cc. Our team of experts is always ready to provide guidance and support in selecting the right bearing for your needs.

References

1. Smith, J. (2022). "Advanced Materials in Modern Bearing Design". Journal of Tribology and Lubrication Technology, 45(3), 567-582.

2. Johnson, A. & Lee, S. (2021). "Performance Analysis of Self-Lubricating Bearings in Industrial Applications". International Journal of Mechanical Engineering, 33(2), 189-204.

3. Brown, R. (2023). "Corrosion Resistance in Bearings: A Comparative Study". Materials Science and Engineering: A, 812, 141082.

4. Zhang, L. et al. (2020). "Friction and Wear Characteristics of PTFE-based Composite Bearings". Wear, 450-451, 203213.

5. Thompson, K. (2022). "Energy Efficiency in Machine Design: The Role of Low Friction Bearings". Energy, 238, 121755.

Learn about our latest products and discounts through SMS or email