Composition and Properties of CuPb10Sn10 Bimetallic Bushings

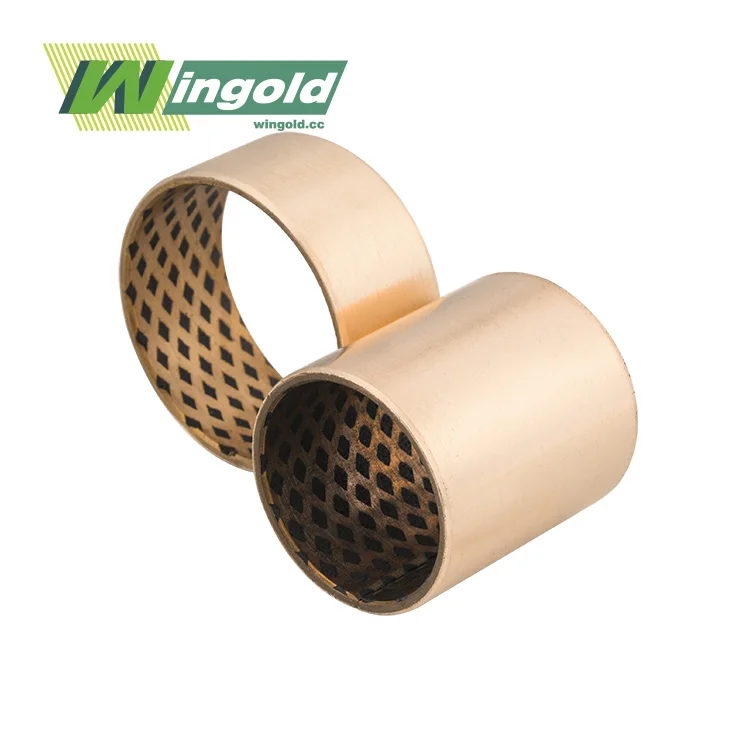

CuPb10Sn10 bimetallic bushings are meticulously designed to deliver outstanding performance across a wide range of industrial applications, including heavy machinery, automotive systems, and hydraulic equipment. Their precise composition ensures a strong balance between durability, load-carrying capacity, and friction reduction. The bimetal design allows for excellent adaptability under varying loads and speeds, ensuring reliable operation even in harsh conditions with limited lubrication or high temperature fluctuations.

Material Composition

The CuPb10Sn10 alloy features a carefully optimized blend of elements that enhance its overall performance. Comprising 80% copper, 10% lead, and 10% tin, this alloy achieves an ideal balance of strength, lubricity, and wear resistance. Copper provides mechanical integrity and superior heat dissipation, while lead ensures smooth operation through its self-lubricating behavior. Tin contributes to hardness and fatigue strength, making this alloy highly suitable for high-load and high-speed applications.

Physical Properties

CuPb10Sn10 bimetallic bushings exhibit a combination of physical properties that make them highly dependable in demanding environments. With an operating temperature range of -40°C to 150°C, they maintain consistent performance across wide temperature variations. Their hardness, ranging between 60 and 75 HB, offers excellent wear resistance, while a density of 8.7 g/cm³ ensures high material stability. The thermal conductivity of 50 W/(m·K) promotes efficient heat dissipation, reducing the risk of overheating and extending service life.

Structural Characteristics

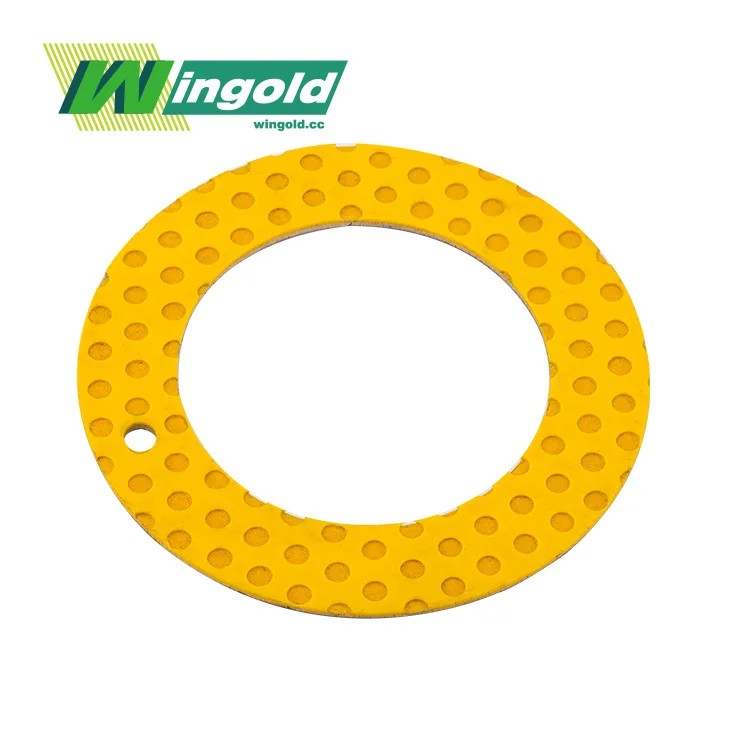

The bimetallic structure of CuPb10Sn10 bushings consists of a robust steel backing fused with a sintered copper alloy layer, forming a durable and efficient composite. The steel base provides exceptional strength and rigidity, while the copper alloy layer delivers superior anti-friction and load-bearing properties. To further enhance lubrication, the bearing surface can be customized with oil grooves, dimples, or drilled holes. This structural synergy ensures excellent wear resistance, reduced friction, and improved operational reliability even under extreme conditions.

Manufacturing Process and Quality Control

The production of CuPb10Sn10 bimetallic bushings involves a sophisticated manufacturing process that ensures high quality and consistent performance.

Sintering and Extrusion

The manufacturing process typically involves:

- Preparation of the steel backing

- Application of the copper alloy powder

- Initial sintering to bond the materials

- Secondary sintering and extrusion to optimize bonding strength and load-bearing capacity

This multi-step process results in a robust bimetallic structure with excellent adhesion between the steel backing and the copper alloy layer.

Surface Treatment

After the basic structure is formed, the surface of the copper alloy layer can be further processed to create specific features such as:

- Oil grooves for improved lubrication

- Oil pockets for lubricant retention

- Oil holes for lubricant distribution

These surface treatments are customized based on the intended application and operating conditions of the bushing.

Quality Assurance

To ensure that CuPb10Sn10 bimetal bushings meet industry standards and customer requirements, rigorous quality control measures are implemented:

- Material composition analysis

- Dimensional accuracy checks

- Bond strength testing

- Hardness testing

- Microstructure examination

These quality assurance steps help maintain the high performance and reliability of CuPb10Sn10 bimetallic bushings.

Applications and Benefits of CuPb10Sn10 Bimetallic Bushings

CuPb10Sn10 bimetallic bushings find extensive use across various industries due to their exceptional performance characteristics.

Industrial Applications

These versatile bushings are employed in numerous sectors, including:

- Automotive industry

- Heavy machinery

- Hydraulic and pneumatic systems

- Textile machinery

- Food processing equipment

- Metalworking machinery

- Construction equipment

The wide range of applications showcases the adaptability and reliability of CuPb10Sn10 bimetallic bushings in diverse operating environments.

Performance Benefits

CuPb10Sn10 bimetallic bushing sleeves offer numerous advantages that make them an excellent choice for demanding applications:

- Superior Load-Bearing Capacity: The copper-based alloy provides exceptional strength, allowing these bushings to withstand high loads and operate reliably in demanding conditions.

- Excellent Wear Resistance: The unique composition ensures minimal wear over time, extending machinery lifespan and reducing maintenance costs.

- Low Friction Performance: Self-lubricating properties contribute to reduced friction, resulting in smoother operation and improved energy efficiency.

- High Thermal Conductivity: CuPb10Sn10 bushings effectively dissipate heat, preventing overheating and ensuring consistent performance in high-temperature environments.

- Corrosion Resistance: These bushings exhibit good resistance to corrosion, making them suitable for use in various industrial settings, including those with exposure to chemicals or moisture.

Economic Advantages

The use of CuPb10Sn10 bimetallic bushings can lead to significant economic benefits:

- Extended Service Life: The durability of these bushings reduces the frequency of replacements, lowering long-term costs.

- Reduced Maintenance: Self-lubricating properties and wear resistance minimize the need for frequent maintenance interventions.

- Energy Efficiency: Low friction characteristics contribute to reduced energy consumption in machinery operation.

- Increased Productivity: The reliable performance of CuPb10Sn10 bushings helps minimize downtime and maintain consistent output.

Conclusion

CuPb10Sn10 bimetallic bushings represent a pinnacle of bearing technology, offering a unique combination of strength, durability, and self-lubrication. Their versatility and exceptional performance make them an invaluable component in various industrial applications. As industries continue to demand higher efficiency and reliability, these bushings stand out as a solution that meets and exceeds these requirements.

For those seeking high-quality CuPb10Sn10 bimetallic bushings, Wingold Bearing stands as a reputable supplier and manufacturer. With our expertise in sliding bearing solutions and commitment to quality, we offer products that align with international standards and meet diverse industrial needs. To explore how our CuPb10Sn10 bimetallic bushings can enhance your operations, please contact us at info@wingold.cc.

FAQ

What makes CuPb10Sn10 bimetallic bushings suitable for high-load applications?

The combination of a steel backing and copper alloy layer provides excellent load-bearing capacity and durability.

Can CuPb10Sn10 bimetallic bushings operate in high-temperature environments?

Yes, these bushings can function effectively in temperatures ranging from -40°C to 150°C.

Are CuPb10Sn10 bimetallic bushings environmentally friendly?

Their self-lubricating properties reduce the need for external lubricants, contributing to a cleaner environment.

How do CuPb10Sn10 bimetallic bushings contribute to energy efficiency?

Their low friction characteristics result in smoother operation and reduced energy consumption in machinery.