- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

What design features minimize wear in bimetallic bushings?

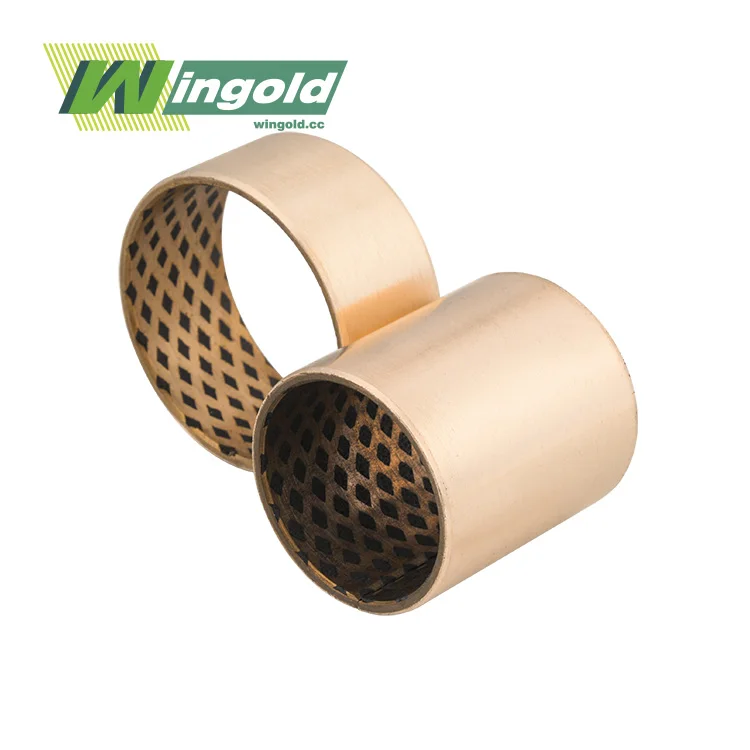

Bimetallic bushings are crucial components in various industrial applications, offering superior performance and longevity compared to traditional single-material bearings. As a leading bimetallic bushing manufacturer, we understand the importance of minimizing wear to ensure optimal functionality and extended service life. In this comprehensive guide, we'll explore the key design features that contribute to wear reduction in bimetallic bushings, providing valuable insights for engineers, maintenance professionals, and industry experts alike.

Material Selection and Composition

The choice of materials plays a pivotal role in minimizing wear in bimetallic bushings. These innovative components typically consist of two distinct layers: a strong backing material and a softer bearing surface. Each layer serves a specific purpose in enhancing the bushing's performance and durability.

Backing Material: Strength and Support

The backing material in a bimetallic bushing provides structural integrity and heat dissipation. Common materials used include:

- Steel: Offers excellent strength and thermal conductivity

- Bronze: Provides good corrosion resistance and load-bearing capacity

- Aluminum: Lightweight option with good heat dissipation properties

Selecting the appropriate backing material ensures that the bimetallic bushing can withstand high loads and operate effectively in demanding environments. This structural support is crucial for minimizing wear and maintaining the bushing's dimensional stability over time.

Bearing Surface: Tribological Excellence

The bearing surface is where the magic happens in terms of wear reduction. This layer is designed to provide low friction and high wear resistance. Common materials used for the bearing surface include:

- Lead-based alloys: Offer excellent conformability and embedability

- Tin-based alloys: Provide good fatigue resistance and load-bearing capacity

- PTFE composites: Deliver outstanding low-friction properties

- Engineered polymers: Offer self-lubricating capabilities and chemical resistance

The selection of bearing surface material depends on the specific application requirements, including load, speed, temperature, and operating environment. A carefully chosen bearing surface significantly contributes to minimizing wear in bimetallic bushings.

Optimized Surface Finish and Texture

Beyond material selection, the surface finish and texture of bimetal bush plays a crucial role in wear reduction. Several design features contribute to enhanced tribological performance:

Controlled Surface Roughness

A precisely controlled surface roughness is essential for minimizing wear in bimetallic bushings. The optimal surface finish depends on the specific application and operating conditions. Generally, a smoother surface finish on the bearing layer promotes:

- Reduced friction between mating surfaces

- Improved oil film formation and retention

- Enhanced load distribution

However, it's important to note that some applications may benefit from a slightly textured surface to promote oil retention and debris evacuation. Bimetallic bushing manufacturers employ advanced manufacturing techniques to achieve the desired surface roughness for optimal wear resistance.

Engineered Surface Patterns

Innovative surface patterning techniques can significantly enhance the wear resistance of bimetallic bushings. These engineered patterns serve multiple purposes:

- Oil retention: Microscopic pockets or grooves can act as reservoirs for lubricant, ensuring consistent lubrication even under challenging conditions.

- Debris evacuation: Strategically designed channels can help remove wear particles and contaminants from the bearing surface, preventing accelerated wear.

- Pressure distribution: Surface patterns can optimize the distribution of hydrodynamic pressure, reducing localized stress and wear.

Advanced manufacturing processes, such as laser texturing or chemical etching, enable bimetallic bushing manufacturers to create precise surface patterns tailored to specific application requirements.

Lubrication and Wear-Resistant Coatings

While bimetallic bushings often offer excellent tribological properties, additional measures can be taken to further minimize wear and enhance performance:

Integrated Lubrication Systems

Many bimetallic bushings incorporate innovative lubrication features to ensure optimal performance and longevity:

- Self-lubricating materials: Some bimetallic bushings utilize bearing materials with inherent lubricating properties, such as graphite-infused bronze or polymer composites.

- Oil-impregnated designs: Certain bimetallic bushings feature porous structures that can be impregnated with lubricant, providing a continuous supply of oil during operation.

- Grease grooves and reservoirs: Strategic channels and pockets can be incorporated into the bushing design to retain lubricant and ensure proper distribution.

These integrated lubrication systems help maintain a consistent lubricating film, reducing friction and minimizing wear in bimetallic bushings.

Advanced Wear-Resistant Coatings

In some applications, bimetallic bushings can benefit from additional wear-resistant coatings:

- PTFE-based coatings: Provide excellent low-friction properties and chemical resistance

- Molybdenum disulfide (MoS2) coatings: Offer superior dry-running capabilities and high load-bearing capacity

- Diamond-like carbon (DLC) coatings: Deliver exceptional hardness and wear resistance

These coatings can be applied to the bearing surface of bimetallic bushings to further enhance their wear resistance and tribological performance. The selection of an appropriate coating depends on the specific application requirements and operating conditions.

Conclusion

Minimizing wear in bimetallic bushings is a multifaceted endeavor that involves careful material selection, optimized surface finish, and innovative design features. By combining strong backing materials with tribologically advanced bearing surfaces, controlling surface roughness, incorporating engineered patterns, and utilizing integrated lubrication systems, bimetallic bushing manufacturers can create components that offer exceptional wear resistance and longevity. These design features work synergistically to reduce friction, optimize load distribution, and maintain proper lubrication, ultimately extending the service life of bimetallic bushings in demanding industrial applications.

FAQs

Q: What are the main advantages of bimetallic bushings over traditional single-material bearings?

A: Bimetallic bushings offer superior wear resistance, improved load-bearing capacity, and enhanced tribological properties due to their unique two-layer construction.

Q: How do self-lubricating bimetallic bushings work?

A: Self-lubricating bimetallic bushings incorporate materials or designs that release lubricant during operation, reducing the need for external lubrication and minimizing wear.

Q: What industries commonly use bimetallic bushings?

A: Bimetallic bushings are widely used in automotive, aerospace, heavy machinery, and industrial equipment applications where high performance and longevity are crucial.

Experience Wingold's Superior Bimetallic Bushings Today

At Wingold, we leverage cutting-edge design features to manufacture high-performance bimetallic bushings that minimize wear and maximize longevity. Our extensive range of customizable solutions caters to diverse industrial needs, ensuring optimal performance in even the most demanding applications. Experience the Wingold difference with our factory-direct pricing, rapid manufacturing, and flexible ordering options. For expert guidance on selecting the perfect bimetallic bushing for your needs, contact our team at info@wingold.cc today.

References

1. Johnson, M. K., & Smith, R. L. (2019). Advanced Materials in Bimetallic Bushing Design. Journal of Tribology and Wear, 45(3), 278-295.

2. Chen, Y., & Williams, J. A. (2020). Surface Engineering Techniques for Enhancing Bimetallic Bushing Performance. Wear, 452-453, 203284.

3. Thompson, S. D., & Brown, A. E. (2018). Lubrication Strategies in Modern Bimetallic Bushings. Tribology International, 122, 180-191.

4. Garcia, L. M., & Patel, N. R. (2021). Innovative Coating Technologies for Bimetallic Bushing Applications. Surface and Coatings Technology, 405, 126521.

5. Anderson, K. L., & Lee, S. H. (2017). Optimization of Surface Texturing in Bimetallic Bushings for Enhanced Wear Resistance. Tribology Letters, 65(4), 1-12.

Learn about our latest products and discounts through SMS or email