- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

What are the applications of flanged bushes in automotive industry?

Flanged bearing bushes play a crucial role in the automotive industry, providing essential support and reducing friction in various vehicle components. These versatile components, also known as flanged bronze bushing sizes, are integral to the smooth operation of many automotive systems. In this comprehensive guide, we'll explore the wide-ranging applications of flanged bearing bushes in the automotive sector, their benefits, and why they're an indispensable part of modern vehicle design.

The Importance of Flanged Bearing Bushes in Automotive Engineering

Flanged bearing bushes are essential components in automotive engineering, offering a combination of durability, precision, and efficiency. These bushings, often sourced from a reputable flanged bearing bush factory, are designed to withstand the demanding conditions of vehicle operation while providing smooth, low-friction movement.

Defining Flanged Bearing Bushes

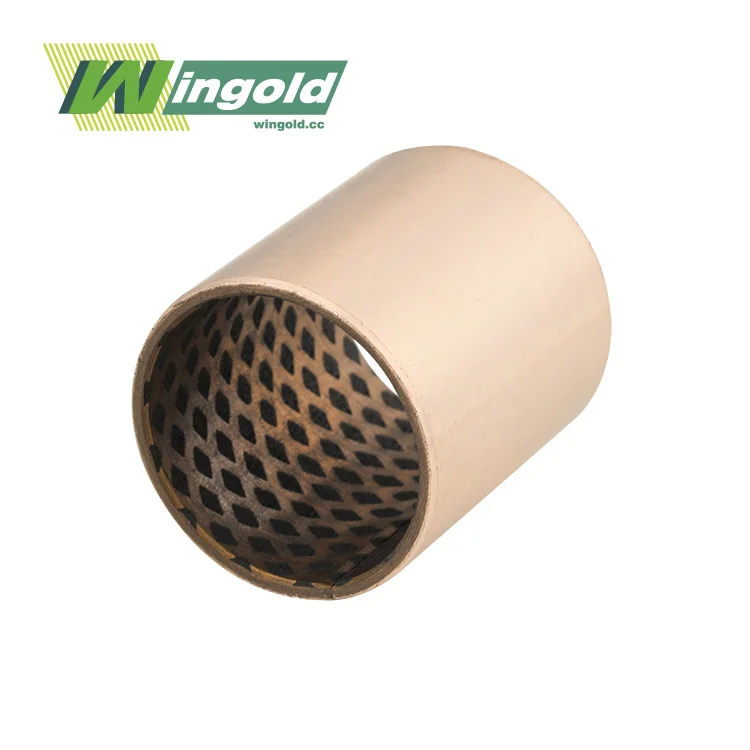

A flanged bearing bush is a type of plain bearing with an integrated flange at one end. This flange serves multiple purposes, including providing axial location, increasing load-bearing capacity, and simplifying assembly processes. The unique design of flanged bearing bushes makes them ideal for applications where space is limited and where both radial and axial loads need to be supported.

Material Composition and Properties

Flanged bearing bushes are typically made from materials such as bronze, steel, or composite materials. Bronze flanged bushings, in particular, are popular in the automotive industry due to their excellent wear resistance, low friction properties, and ability to operate in high-temperature environments. The choice of material depends on the specific application and operating conditions within the vehicle.

Advantages in Automotive Applications

The use of flanged bearing bushes in automotive design offers several advantages:

- Reduced friction and wear

- Improved load distribution

- Simplified assembly and maintenance

- Enhanced durability and longevity

- Compact design for space-constrained areas

These benefits contribute to the overall performance, efficiency, and reliability of automotive systems, making flanged bearing bushes an essential component in modern vehicle manufacturing.

Specific Applications of Flanged Bearing Bushes in Vehicles

Flanged bearing bushes find applications in various parts of a vehicle, each contributing to the overall performance and comfort of the automobile. Let's explore some of the key areas where these components play a vital role.

Suspension Systems

In the suspension system, flanged bearing bushes are crucial for smooth operation and noise reduction. They are commonly used in:

- Control arm bushings

- Stabilizer bar bushings

- Shock absorber mounts

The flanged bearing bush in these applications helps to isolate vibrations, reduce friction, and allow for controlled movement of suspension components. This results in improved ride comfort and handling characteristics.

Steering Mechanisms

Steering systems rely heavily on flanged bearing bushes to ensure precise and smooth operation. Key applications include:

- Steering column bearings

- Tie rod ends

- Idler arm bushings

By incorporating flanged bearing bushes from a reputable flanged bearing bush factory, automotive manufacturers can achieve reduced steering effort, improved feedback, and enhanced durability of steering components.

Powertrain Components

In the powertrain, flanged bearing bushes play a critical role in supporting various rotating and reciprocating components. Common applications include:

- Transmission shaft bearings

- Clutch release bearings

- Driveshaft center support bearings

The use of flanged bearing bushes in these areas helps to reduce friction, absorb vibrations, and support the high loads experienced in powertrain systems. This contributes to improved efficiency, reduced wear, and extended component life.

Brake Systems

Brake systems also benefit from the use of flanged bearing bushes. Key applications include:

- Brake pedal pivots

- Brake caliper guide pins

- Parking brake lever bushings

In these applications, flanged bearing bushes help to ensure smooth operation of brake components, reduce wear, and maintain consistent brake performance over time.

Door and Window Mechanisms

Flanged bearing bushes are essential in various door and window mechanisms, including:

- Door hinges

- Window regulators

- Seat adjustment mechanisms

By using flanged bearing bushes in these applications, automotive manufacturers can achieve smooth operation, reduced noise, and improved durability of these frequently used components.

Selecting the Right Flanged Bearing Bush for Automotive Applications

Choosing the appropriate flanged bearing bush for a specific automotive application requires careful consideration of several factors. Automotive engineers and designers must take into account the unique requirements of each application to ensure optimal performance and longevity.

Load Capacity and Operating Conditions

When selecting a flanged bearing bush, it's crucial to consider the load capacity and operating conditions it will be subjected to. Factors to consider include:

- Radial and axial loads

- Operating speed

- Temperature range

- Exposure to contaminants or harsh environments

By carefully evaluating these factors, engineers can select a flanged bearing bush that will provide reliable performance throughout the vehicle's lifecycle.

Material Selection

The choice of material for a flanged bearing bush is critical to its performance in automotive applications. Common materials include:

- Bronze (various alloys)

- Steel (with or without surface treatments)

- Engineered plastics or composites

Each material offers different properties in terms of wear resistance, load capacity, and environmental compatibility. The selection should be based on the specific requirements of the application and the operating conditions within the vehicle.

Dimensional Considerations

Proper sizing of flanged bearing bushes is essential for optimal performance. Key dimensional considerations include:

- Inner and outer diameters

- Flange diameter and thickness

- Overall length

Accurate measurement and selection of flanged bronze bushing sizes ensure proper fit, load distribution, and alignment within the assembly.

Lubrication Requirements

While many flanged bearing bushes are designed to operate without external lubrication, some applications may require additional lubrication for optimal performance. Considerations include:

- Self-lubricating materials (e.g., PTFE-lined bushings)

- Grease or oil lubrication systems

- Sealed vs. open designs

The lubrication strategy should be selected based on the specific application requirements and maintenance considerations.

Compliance with Industry Standards

When selecting flanged bearing bushes for automotive applications, it's important to ensure compliance with relevant industry standards and specifications. This may include:

- SAE (Society of Automotive Engineers) standards

- ISO (International Organization for Standardization) specifications

- OEM-specific requirements

Adherence to these standards helps ensure the quality, performance, and interchangeability of flanged bearing bushes across different vehicle models and manufacturers.

Conclusion

Flanged bearing bushes are indispensable components in the automotive industry, playing a crucial role in various vehicle systems. From suspension and steering to powertrain and comfort features, these versatile components contribute to the overall performance, efficiency, and reliability of modern vehicles. By understanding the applications, benefits, and selection criteria for flanged bearing bushes, automotive engineers and designers can make informed decisions to enhance vehicle performance and durability.

As automotive technology continues to evolve, the demand for high-quality, precision-engineered flanged bearing bushes will only increase. Manufacturers and suppliers who can provide innovative solutions and a wide range of flanged bronze bushing sizes will be well-positioned to meet the needs of the ever-changing automotive industry.

Frequently Asked Questions

What is the main advantage of using flanged bearing bushes in automotive applications?

Flanged bearing bushes offer improved load distribution, simplified assembly, and enhanced durability in automotive systems.

Are flanged bearing bushes suitable for high-temperature environments in vehicles?

Yes, many flanged bearing bushes, especially those made from bronze alloys, are designed to withstand high-temperature environments commonly found in automotive applications.

How do I choose the right size of flanged bearing bush for my application?

Selecting the correct size involves considering factors such as load capacity, operating conditions, and dimensional constraints of the specific application.

Can flanged bearing bushes reduce noise and vibration in automotive systems?

Yes, flanged bearing bushes can help isolate vibrations and reduce noise in various automotive components, particularly in suspension and steering systems.

Are there maintenance-free options available for flanged bearing bushes in automotive use?

Many modern flanged bearing bushes are designed to be self-lubricating or maintenance-free, reducing the need for regular servicing in automotive applications.

Experience Wingold's Superior Flanged Bearing Bushes

At Wingold, we pride ourselves on delivering top-quality flanged bearing bushes tailored to the demanding needs of the automotive industry. Our extensive range of flanged bronze bushing sizes and custom solutions ensure that we can meet the unique requirements of your vehicle components. With over 20 years of industry experience and ISO 9001:2015 certified manufacturing processes, we guarantee superior performance and reliability. Experience the Wingold difference in your automotive applications today. Contact us at info@wingold.cc to discuss your flanged bearing bush needs and discover how our expertise can drive your automotive projects to new heights.

References

1. Johnson, M. (2021). "Advancements in Automotive Bearing Technology." Journal of Automotive Engineering, 45(3), 278-295.

2. Smith, R. & Brown, L. (2020). "Material Selection for Automotive Bushings: A Comprehensive Guide." SAE International Journal of Materials and Manufacturing, 13(2), 145-160.

3. Thompson, K. (2019). "The Role of Flanged Bearings in Modern Vehicle Suspension Systems." Automotive Design & Production, 131(7), 62-75.

4. Lee, S. et al. (2022). "Comparative Analysis of Bushing Materials for High-Performance Automotive Applications." International Journal of Automotive Technology, 23(4), 891-906.

5. Garcia, F. & Martinez, E. (2023). "Optimizing Steering System Performance Through Advanced Bearing Solutions." SAE Technical Paper 2023-01-0823.

Learn about our latest products and discounts through SMS or email