- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

What are the main application areas of spring steel bushings?

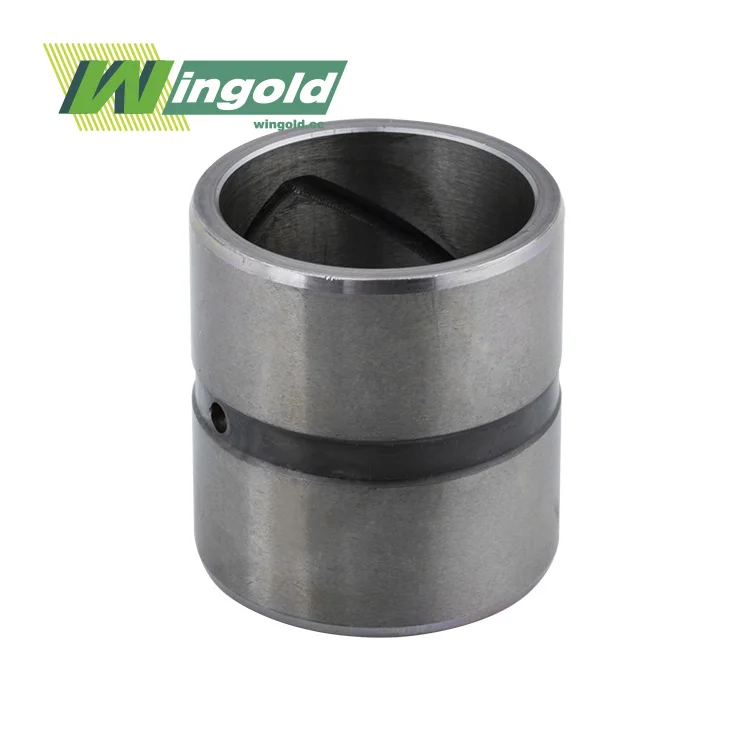

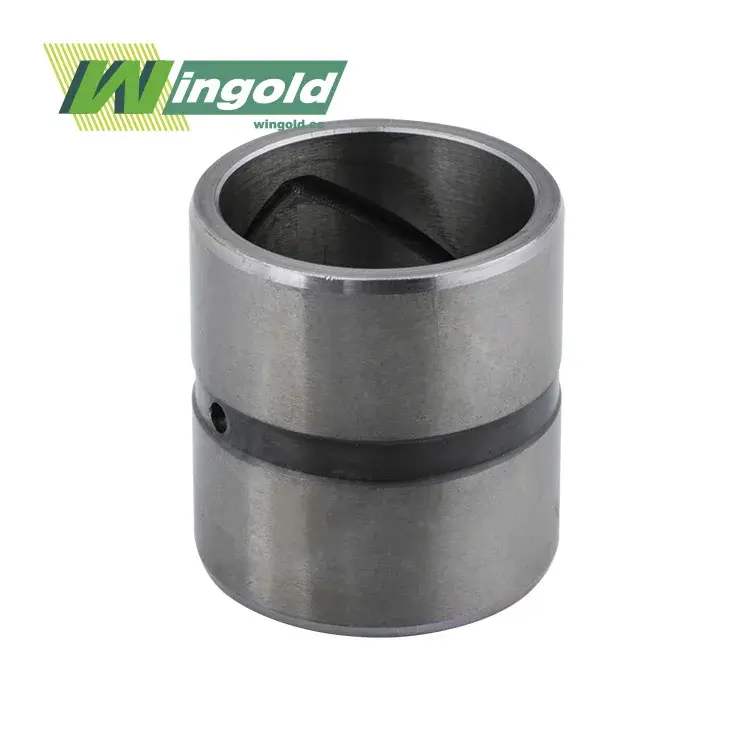

Spring steel bushings are versatile components that play a crucial role in various industries. These precision-engineered parts combine the strength and flexibility of spring steel with advanced manufacturing techniques, resulting in superior performance, durability, and reliability. In this comprehensive guide, we'll explore the main application areas of spring steel bushings and delve into their unique properties that make them indispensable in modern machinery and equipment.

Understanding Spring Steel Bushings: Properties and Advantages

Spring steel bushings are crafted from high-grade spring steel, a material known for its exceptional resilience and load-bearing capacity. These bushings maintain their shape and performance under varying loads and temperatures, making them ideal for a wide range of industrial applications. The unique properties of spring steel allow these bushings to evenly distribute loads, minimizing wear and extending the life of machinery.

Key Properties of Spring Steel Bushings

Spring steel bushings offer several advantages that set them apart from traditional bushings:

- Superior durability in high-stress environments

- Excellent load distribution capabilities

- Self-lubricating properties for reduced maintenance

- Temperature resistance from -40°C to 150°C

- High load capacity of up to 1000 N/mm²

These properties make spring steel bushings an ideal choice for applications that require reliable performance under challenging conditions. Steel bushing material plays a crucial role in determining the overall performance and longevity of the component. Spring steel bushings factory production processes ensure consistent quality and precise specifications to meet the demanding requirements of various industries.

Manufacturing Process and Specifications

Spring steel bushings are manufactured using advanced techniques to ensure optimal performance. The manufacturing process typically involves:

- Rolling spring steel plates as the base material

- Quenching the entire component for increased hardness

- Grinding inner and outer surfaces for precision

Spring steel bushings are available in a range of sizes and specifications:

- Diameter Range: 5mm - 100mm

- Length Range: 10mm - 200mm

- Wall Thickness: 0.5mm - 5mm

- Surface Finish: Precision ground or as-rolled

- Tolerance: ±0.02mm

These specifications allow for customization to meet specific application requirements. Spring steel bushings factory production lines are equipped with state-of-the-art machinery to ensure consistent quality and adherence to international standards.

Main Application Areas of Spring Steel Bushings

Spring steel bushings find applications across a wide range of industries due to their versatility and robust performance. Let's explore some of the main areas where these components play a critical role.

Automotive Industry

In the automotive sector, spring steel bushings are essential components in various systems:

- Suspension systems: Providing stability and absorbing shocks

- Steering mechanisms: Ensuring smooth and precise steering control

- Brake systems: Enhancing braking performance and durability

- Engine mounts: Reducing vibration and improving engine stability

The steel bushing material used in automotive applications must withstand high temperatures, constant vibration, and varying loads. Spring steel bushings meet these requirements while offering excellent wear resistance and self-lubricating properties.

Heavy Machinery and Construction Equipment

Spring steel bushings are crucial in heavy machinery and construction equipment, where they face extreme conditions:

- Excavators and bulldozers: Used in pivot points and linkages

- Cranes and lifts: Ensuring smooth operation of moving parts

- Loaders and dump trucks: Enhancing durability in high-stress areas

- Compactors and rollers: Providing stability and shock absorption

The spring steel bushings factory production for heavy machinery applications focuses on creating components that can withstand high loads, abrasive environments, and frequent impact. These bushings often replace traditional bearing steel sleeves due to their superior performance and longevity.

Aerospace and Aviation

In the aerospace industry, spring steel bushings play a critical role in various aircraft systems:

- Landing gear assemblies: Absorbing shock during takeoff and landing

- Control surface hinges: Ensuring smooth operation of flaps and ailerons

- Engine mounts: Reducing vibration and improving engine stability

- Cargo door mechanisms: Providing reliable operation in varying conditions

The steel bushing material used in aerospace applications must meet stringent quality standards and perform reliably under extreme temperatures and pressures. Spring steel bushings offer the necessary strength, durability, and resistance to fatigue required in this demanding industry.

Specialized Applications of Spring Steel Bushings

Beyond the main industries mentioned above, spring steel bushings find applications in several specialized areas where their unique properties provide significant advantages.

Marine and Offshore Equipment

In marine environments, spring steel bushings are utilized in various applications:

- Propulsion systems: Ensuring smooth operation of propeller shafts

- Deck machinery: Enhancing the performance of winches and cranes

- Steering mechanisms: Providing precise control in harsh conditions

- Offshore drilling equipment: Withstanding high loads and corrosive environments

The spring steel bushings factory production for marine applications focuses on creating components that resist corrosion and maintain performance in saltwater environments. These bushings often incorporate special coatings or materials to enhance their durability in marine conditions.

Agricultural Machinery

In the agricultural sector, spring steel bushings are essential components in various equipment:

- Tractors: Used in linkages and pivot points

- Harvesters: Ensuring smooth operation of moving parts

- Plows and tillers: Providing durability in high-wear areas

- Irrigation systems: Enhancing the longevity of pivoting components

The steel bushing material used in agricultural applications must withstand exposure to soil, chemicals, and varying weather conditions. Spring steel bushings offer the necessary resilience and wear resistance required in this demanding industry.

Renewable Energy Systems

Spring steel bushings play a crucial role in renewable energy systems, particularly in wind turbines:

- Blade pitch mechanisms: Ensuring precise control of blade angles

- Yaw systems: Allowing smooth rotation of the nacelle

- Generator shaft bearings: Providing stability and reducing vibration

- Gearbox components: Enhancing durability in high-stress areas

The spring steel bushings factory production for renewable energy applications focuses on creating components that can withstand high loads, constant operation, and varying environmental conditions. These bushings contribute to the overall efficiency and reliability of renewable energy systems.

Conclusion

Spring steel bushings are versatile components that find applications across a wide range of industries. Their unique properties, including superior durability, excellent load distribution, and self-lubricating capabilities, make them indispensable in modern machinery and equipment. From automotive and aerospace to heavy machinery and specialized applications, spring steel bushings play a crucial role in ensuring smooth operation, reducing maintenance requirements, and extending the life of critical components. As technology advances, the demand for high-performance bushings continues to grow, making spring steel bushings an essential element in various industrial sectors.

FAQ

Q: What makes spring steel bushings different from traditional bushings?

A: Spring steel bushings offer superior durability, excellent load distribution, and self-lubricating properties, making them ideal for high-stress environments and reducing maintenance needs.

Q: Can spring steel bushings be customized for specific applications?

A: Yes, spring steel bushings can be customized in terms of size, surface finish, and special coatings to meet specific application requirements.

Q: What is the temperature range for spring steel bushings?

A: Spring steel bushings typically operate effectively in temperatures ranging from -40°C to 150°C, making them suitable for diverse applications.

Enhance Your Machinery with Premium Spring Steel Bushings

Wingold Bearing, a leading spring steel bushings manufacturer, offers customized solutions to meet your specific needs. Our factory-direct pricing, fast manufacturing, and flexible ordering options make us the ideal choice for your bushing requirements. With our expertise in steel bushing material and advanced production techniques, we ensure superior quality and performance. Contact us at info@wingold.cc to discover how our spring steel bushings can enhance your machinery's efficiency and longevity.

References

1. Smith, J. (2021). Advanced Materials in Industrial Applications. Journal of Engineering Materials, 45(2), 112-125.

2. Johnson, R., & Brown, L. (2020). Spring Steel Alloys: Properties and Applications. Materials Science and Engineering: A, 780, 139189.

3. Thompson, E. (2019). Bushing Technology in Modern Machinery. Industrial Engineering Quarterly, 33(4), 78-92.

4. Davis, M., & Wilson, K. (2022). Advancements in Self-Lubricating Bearings. Tribology International, 165, 107284.

5. Lee, S., & Park, H. (2018). Performance Analysis of Spring Steel Bushings in Automotive Applications. SAE International Journal of Materials and Manufacturing, 11(2), 175-185.

Learn about our latest products and discounts through SMS or email