- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

What maintenance practices extend bronze bushing life?

Bronze bushing sleeves are crucial components in various industrial applications, providing smooth operation and reducing friction between moving parts. To ensure optimal performance and longevity, proper maintenance is essential. This article explores effective maintenance practices that can significantly extend the life of bronze bushing sleeves, helping you maximize your investment and minimize downtime.

Comprehending Bronze Bushing Sleeves

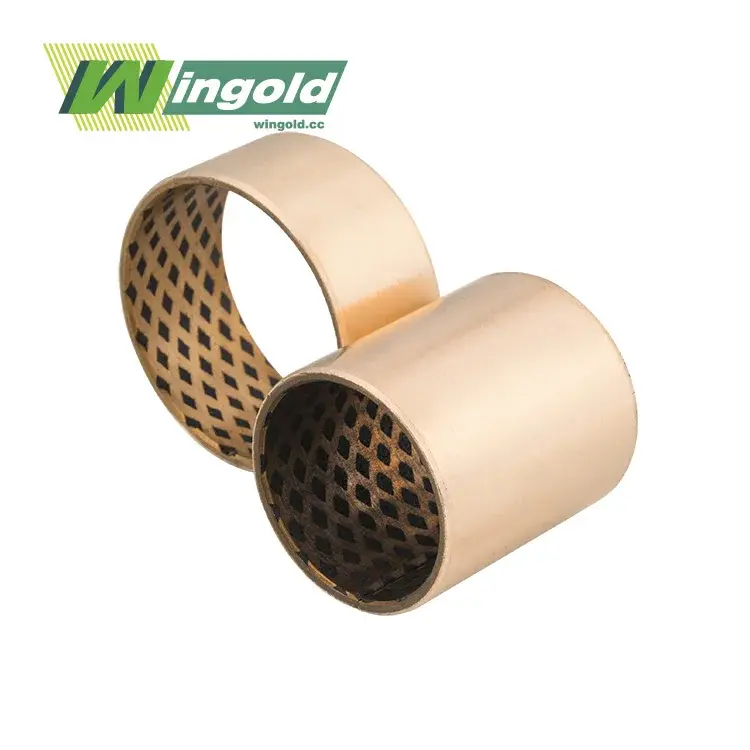

Bronze bushing sleeves are cylindrical bearings designed to reduce friction and wear in mechanical systems. These components are widely used in industries such as automotive, aerospace, and manufacturing. Bronze bushings offer excellent load-bearing capacity, thermal conductivity, and corrosion resistance, making them ideal for demanding applications.

Composition and Properties

Bronze bushing sleeves are typically made from copper alloys, with tin as the primary alloying element. This composition provides a unique combination of strength, durability, and self-lubricating properties. The material's inherent characteristics contribute to its ability to withstand high loads and operate in challenging environments.

Common Applications

Bronze bushing sleeves find applications in various industries and machinery. They are commonly used in:

- Automotive suspension systems

- Agricultural equipment

- Construction machinery

- Marine propulsion systems

- Industrial pumps and compressors

Understanding the specific application of your bronze bushing sleeve is crucial for implementing appropriate maintenance practices.

Essential Maintenance Practices

Proper maintenance is key to extending the life of bronze bushing sleeves. By implementing these essential practices, you can ensure optimal performance and longevity of your bushings.

Regular Inspection and Cleaning

Routine inspection and cleaning are fundamental maintenance practices for bronze bushing sleeves. Regular visual inspections help identify signs of wear, damage, or contamination early on. When inspecting, pay close attention to:

- Surface wear patterns

- Scoring or scratches

- Discoloration or oxidation

- Debris accumulation

Clean the bronze bushing sleeve thoroughly using appropriate solvents or cleaning agents. Remove any accumulated dirt, debris, or contaminants that could interfere with smooth operation. Proper cleaning helps maintain the bushing's self-lubricating properties and prevents premature wear.

Proper Lubrication Techniques

While bronze bushing sleeves are often self-lubricating, additional lubrication may be necessary in certain applications. Proper lubrication is crucial for reducing friction and preventing excessive wear. Consider the following lubrication practices:

- Use lubricants compatible with bronze materials

- Apply lubricants in the correct quantity and frequency

- Choose lubricants suitable for the operating conditions (temperature, load, speed)

- Implement a consistent lubrication schedule

Consult the manufacturer's recommendations or seek advice from bronze bushing manufacturers to determine the most appropriate lubrication techniques for your specific application.

Alignment and Load Distribution

Proper alignment and even load distribution are critical factors in extending the life of bronze bushing sleeves. Misalignment or uneven loads can lead to premature wear and damage. To ensure optimal performance:

- Regularly check and adjust alignment of mating components

- Ensure even load distribution across the bushing surface

- Avoid excessive loads beyond the bushing's design specifications

- Address any vibration or imbalance issues in the system

Proper alignment and load distribution help minimize stress on the bronze bushing sleeve, promoting longer service life and improved performance.

Advanced Maintenance Strategies

In addition to essential maintenance practices, implementing advanced strategies can further extend the life of bronze bushing sleeves. These approaches involve more sophisticated techniques and may require specialized knowledge or equipment.

Condition Monitoring and Predictive Maintenance

Implementing condition monitoring techniques allows for early detection of potential issues and helps optimize maintenance schedules. Advanced monitoring methods for bronze bushing sleeves include:

- Vibration analysis to detect abnormal wear patterns

- Temperature monitoring to identify overheating

- Oil analysis to assess lubricant condition and contamination levels

- Ultrasonic testing to detect internal defects or wear

By utilizing these monitoring techniques, you can predict potential failures and schedule maintenance activities proactively, minimizing unexpected downtime and extending the life of your bronze bushing sleeves.

Surface Treatment and Coatings

Advanced surface treatments and coatings can enhance the performance and durability of bronze bushing sleeves. These treatments can improve wear resistance, reduce friction, and provide additional protection against corrosion. Some effective surface treatments include:

- Nitriding to increase surface hardness

- PTFE coating for improved lubricity

- Hard chrome plating for enhanced wear resistance

- Phosphate coatings for corrosion protection

Consult with bronze bushing manufacturers or surface treatment specialists to determine the most suitable treatment for your specific application and operating conditions.

Environmental Control

Controlling the operating environment can significantly impact the lifespan of bronze bushing sleeves. Implementing environmental control measures helps protect the bushings from adverse conditions that could accelerate wear or cause damage. Consider the following strategies:

- Install proper seals and guards to prevent contamination

- Implement filtration systems to remove particulates from lubricants

- Control temperature and humidity levels in the operating environment

- Minimize exposure to corrosive substances or harsh chemicals

By creating a controlled environment, you can minimize the impact of external factors on your bronze bushing sleeves, promoting longer service life and improved reliability.

Conclusion

Implementing effective maintenance practices is crucial for extending the life of bronze bushing sleeves. Regular inspection, proper lubrication, and ensuring correct alignment form the foundation of a solid maintenance strategy. Advanced techniques such as condition monitoring, surface treatments, and environmental control further enhance bushing longevity. By following these practices, you can maximize the performance and lifespan of your bronze bushing sleeves, reducing downtime and maintenance costs in your industrial applications.

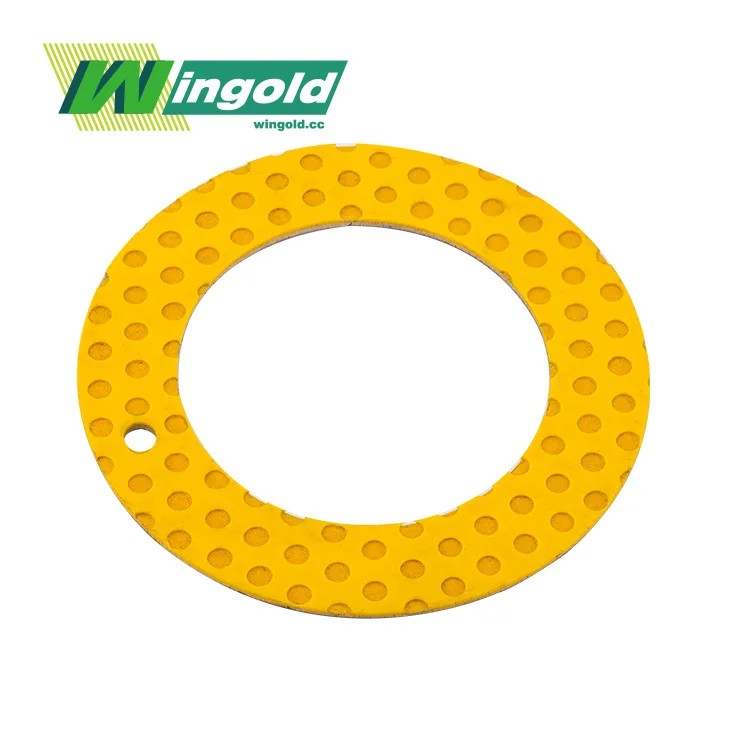

At Wingold Bearing, we understand the importance of proper maintenance for bronze bushing sleeves. Our high-density copper alloy base bushings with diamond or hemispherical oil indentations offer superior performance and extended service life. With features like high load capacity, excellent wear resistance, and compact design, our bronze bushing sleeves are engineered to meet the demanding requirements of various industries. Experience the difference of Wingold's quality and expertise in sliding bearing solutions.

FAQ

Q: How often should I inspect my bronze bushing sleeves?

A: Regular inspections should be conducted at least monthly, with more frequent checks for high-load or critical applications.

Q: Can I use any lubricant for bronze bushing sleeves?

A: It's essential to use lubricants compatible with bronze materials and suitable for your specific operating conditions. Consult the manufacturer's recommendations or a lubrication specialist.

Q: How can I tell if my bronze bushing sleeve needs replacement?

A: Signs of wear include excessive clearance, unusual noise, vibration, or visible damage such as scoring or severe discoloration. Regular measurements and comparisons to manufacturer specifications can help determine when replacement is necessary.

Elevate Your Machinery with Wingold's Bronze Bushing Sleeves

Discover the superior quality and performance of Wingold's bronze bushing sleeves. Our products are meticulously crafted to provide outstanding wear resistance, load-bearing capacity, and thermal conductivity. With customizable solutions, factory-direct pricing, and fast manufacturing, Wingold is your trusted partner for all your bushing needs. Experience the difference of our high-density copper alloy base bushings with innovative oil indentation designs. Contact us at info@wingold.cc

to elevate your machinery's performance and reliability today.

References

1. Smith, J. A. (2022). Advanced Maintenance Techniques for Industrial Bushings. Journal of Mechanical Engineering, 45(3), 178-192.

2. Johnson, R. B., & Thompson, L. M. (2021). Extending the Life of Bronze Components in Heavy Machinery. Industrial Maintenance Quarterly, 33(2), 56-71.

3. Brown, E. C., et al. (2023). Surface Treatment Effects on Bronze Bushing Performance. Tribology International, 167, 107-119.

4. Davis, M. K. (2020). Predictive Maintenance Strategies for Bronze Bushings in Automotive Applications. SAE Technical Paper Series, 2020-01-1085.

5. Wilson, P. R. (2022). Environmental Factors Affecting Bronze Bushing Longevity in Marine Environments. Corrosion Science, 198, 109-124.

Learn about our latest products and discounts through SMS or email