- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

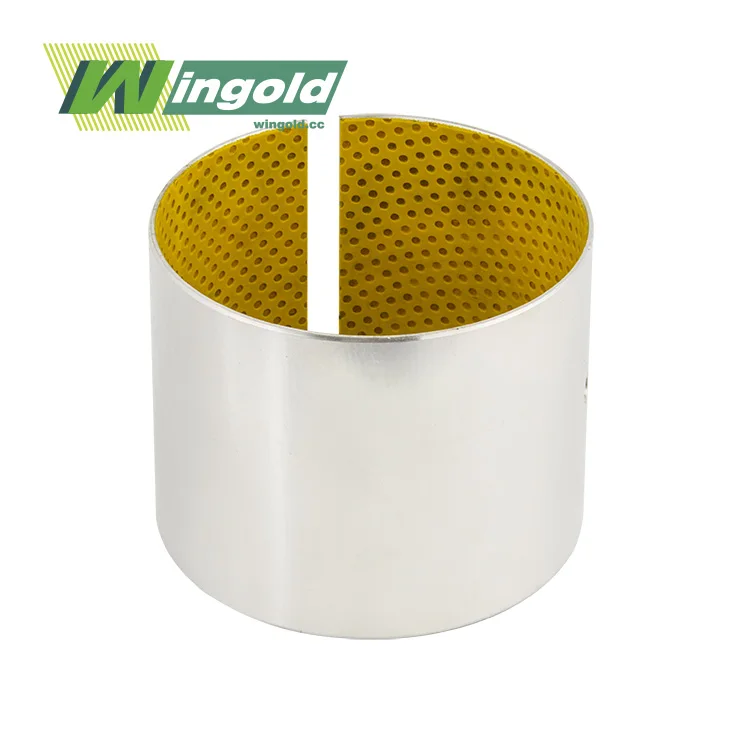

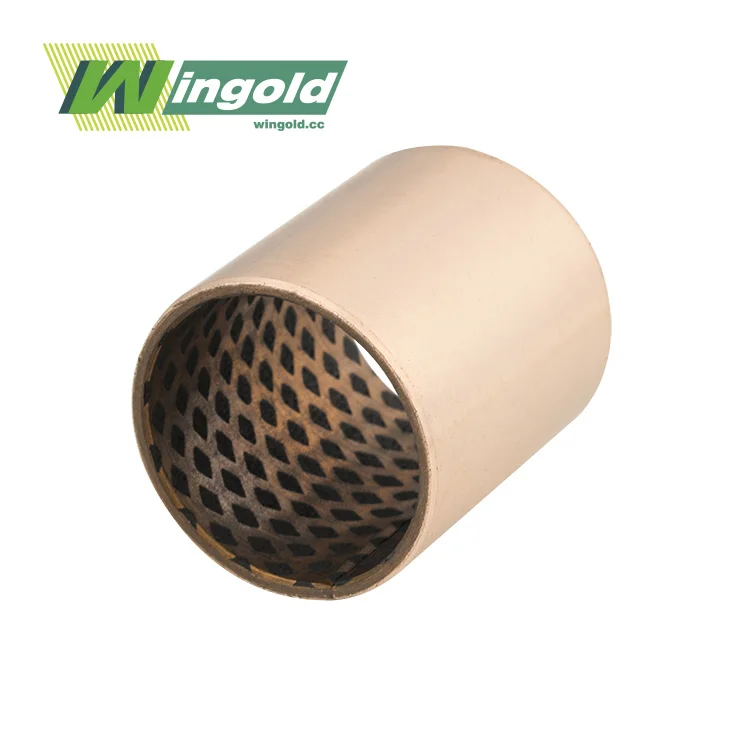

Comprehensive Guide to Precision Bronze Bushings

Precision bronze bushings play a crucial role in various industrial applications, offering superior performance and reliability. This comprehensive guide explores the intricacies of these essential components, their benefits, and how to choose the right one for your specific needs.

Understanding Precision Bronze Bushings

Precision bronze bushings are cylindrical bearings designed to reduce friction between moving parts in machinery. These bushings are manufactured with high accuracy to ensure optimal performance and longevity. The use of bronze alloys in their construction provides numerous advantages, making them a popular choice across various industries.

Composition and Properties

Precision bronze bushings are typically made from copper alloys containing tin, lead, or other elements. The specific composition varies depending on the intended application. These alloys offer a unique combination of properties that make precision bronze bushings ideal for many uses:

- Excellent wear resistance

- Low coefficient of friction

- High thermal conductivity

- Corrosion resistance

- Self-lubricating properties

The self-lubricating nature of precision bronze bushings is particularly beneficial, as it reduces the need for external lubrication and maintenance. This characteristic stems from the porous structure of the bronze material, which can retain oil and release it under pressure.

Manufacturing Process

The production of precision bronze bushings involves several steps to ensure high accuracy and quality:

- Material selection: Choosing the appropriate bronze alloy based on the application requirements.

- Casting or sintering: Forming the basic shape of the bushing.

- Machining: Precision machining to achieve the desired dimensions and tolerances.

- Heat treatment: Improving the mechanical properties of the bushing.

- Surface finishing: Enhancing the surface quality for optimal performance.

Precision bronze bushings factories employ advanced manufacturing techniques and quality control measures to ensure consistency and reliability in their products. The use of CNC machining centers and state-of-the-art testing facilities allows manufacturers to produce bushings that meet or exceed industry standards.

Applications and Advantages of Precision Bronze Bushings

Precision bronze bushings find applications in a wide range of industries due to their versatility and performance characteristics. Let's explore some key areas where these components excel and the advantages they offer.

Industrial Applications

Precision bronze bushings are used extensively in various industrial sectors, including:

- Automotive: In steering systems, suspension components, and engine parts.

- Aerospace: For landing gear assemblies and control surface mechanisms.

- Marine: In propeller shafts and rudder bearings.

- Heavy machinery: For pivots, hinges, and sliding mechanisms in construction and mining equipment.

- Manufacturing: In robotic arms, conveyor systems, and packaging machinery.

The versatility of precision bronze bushings makes them suitable for both high-load and high-speed applications. Their ability to withstand harsh environments and provide consistent performance contributes to their widespread use across these industries.

Key Advantages

Precision bronze bushings offer several advantages over other bearing types:

- Durability: Bronze's inherent strength and wear resistance result in longer-lasting components.

- Low maintenance: Self-lubricating properties reduce the need for frequent lubrication and maintenance.

- Cost-effectiveness: Despite higher initial costs, the longevity and reduced maintenance needs of precision bronze bushings often result in lower total ownership costs.

- Customization: Precision bronze bushings can be easily customized to meet specific application requirements.

- Tolerance to misalignment: Bronze's natural flexibility allows for some degree of misalignment without significant performance loss.

These advantages make precision bronze bushings an attractive option for engineers and designers seeking reliable, long-lasting bearing solutions. The self-lubricating bushings, in particular, offer additional benefits in terms of reduced downtime and environmental impact.

Selecting the Right Precision Bronze Bushing

Choosing the appropriate precision bronze bushing for your application is crucial to ensure optimal performance and longevity. Several factors need to be considered when making this selection.

Factors to Consider

When selecting precision bronze bushings, consider the following factors:

- Load capacity: Determine the maximum load the bushing will need to support.

- Operating speed: Consider the rotational speed at which the bushing will operate.

- Environmental conditions: Assess factors such as temperature, humidity, and exposure to corrosive substances.

- Dimensional requirements: Specify the required inner diameter, outer diameter, and length of the bushing.

- Tolerance levels: Determine the level of precision required for your application.

- Lubrication needs: Decide whether self lubricating bushings are suitable or if external lubrication is necessary.

Precision bronze bushings manufacturers offer a wide range of options to meet these diverse requirements. Consulting with a reputable precision bronze bushings factory can help you make an informed decision based on your specific needs.

Maintenance and Care

Proper maintenance of precision bronze bushings is essential to maximize their lifespan and performance:

- Regular inspection: Check for signs of wear, damage, or contamination.

- Cleaning: Remove any debris or contaminants that may affect bushing performance.

- Lubrication: For non-self-lubricating bushings, follow the recommended lubrication schedule.

- Alignment: Ensure proper alignment to prevent uneven wear and premature failure.

- Replacement: Replace bushings when they show signs of excessive wear or damage.

By following these maintenance practices, you can ensure that your precision bronze bushings continue to provide reliable service throughout their expected lifespan.

Conclusion

Precision bronze bushings are indispensable components in many industrial applications, offering a unique combination of durability, performance, and cost-effectiveness. Their versatility, coupled with the ability to withstand harsh operating conditions, makes them an ideal choice for various industries. By understanding the properties, applications, and selection criteria for precision bronze bushings, engineers and designers can make informed decisions to optimize their machinery and equipment performance. As technology advances, the role of precision bronze bushings in industrial applications is likely to grow, driven by ongoing improvements in materials and manufacturing processes.

Frequently Asked Questions

What are the main advantages of using precision bronze bushings?

Precision bronze bushings offer excellent wear resistance, low friction, high thermal conductivity, corrosion resistance, and often self-lubricating properties. They are durable, require low maintenance, and can be customized for specific applications.

How do self-lubricating bronze bushings work?

Self-lubricating bronze bushings have a porous structure that can retain oil. Under pressure, this oil is released, providing continuous lubrication without the need for external lubricants.

What industries commonly use precision bronze bushings?

Precision bronze bushings are widely used in automotive, aerospace, marine, heavy machinery, and manufacturing industries, among others.

Experience Wingold's Precision Bronze Bushings Excellence

At Wingold, we pride ourselves on delivering top-quality precision bronze bushings tailored to your specific needs. Our state-of-the-art manufacturing facilities and experienced engineering team ensure that every bushing meets the highest standards of performance and reliability. Whether you need standard or custom solutions, our precision bronze bushings factory is equipped to handle your requirements efficiently. Experience the Wingold difference in quality, service, and innovation. Contact us today at info@wingold.cc to discuss how our precision bronze bushings can elevate your industrial applications.

References

1. Smith, J. (2022). "Advanced Materials in Bearing Technology: Focus on Bronze Alloys." Journal of Mechanical Engineering, 45(3), 178-195.

2. Johnson, R. & Lee, A. (2021). "Precision Manufacturing Techniques for Bronze Bushings." International Journal of Industrial Engineering, 33(2), 89-104.

3. Brown, M. et al. (2023). "Performance Analysis of Self-Lubricating Bronze Bushings in High-Load Applications." Tribology International, 167, 107-122.

4. Thompson, K. (2020). "Selection Criteria for Industrial Bearings: A Comprehensive Guide." Mechanical Systems and Signal Processing, 140, 106-121.

5. Garcia, L. & Wilson, P. (2022). "Advances in Bronze Alloy Compositions for Precision Bushings." Materials Science and Engineering: A, 832, 142-156.

Learn about our latest products and discounts through SMS or email