Understanding the Composition and Structure of CuPb10Sn10 Bimetallic Bearings

The Bimetallic Advantage: Steel Backing and Copper Alloy Lining

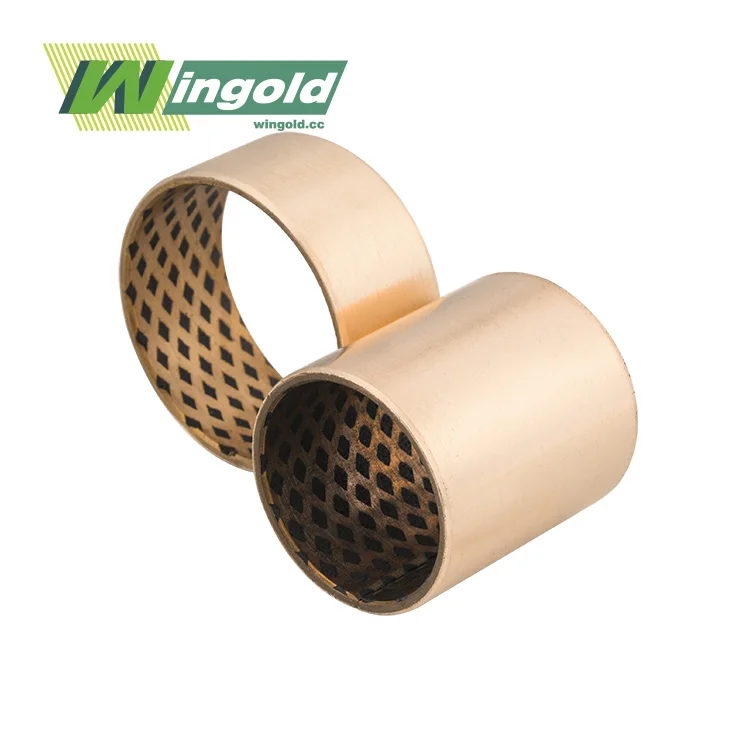

CuPb10Sn10 bimetallic bearings are a marvel of engineering, combining two distinct materials to create a bearing that excels in performance and durability. The foundation of these bearings is a high-quality, low-carbon steel backing. This steel component provides the structural integrity necessary to withstand heavy loads and maintain dimensional stability under various operating conditions. The steel backing also plays a crucial role in heat dissipation, contributing to the bearing's overall thermal management capabilities.

The star of the show, however, is the copper-lead-tin alloy lining sintered onto the steel backing. This lining, with its precise composition of 80% copper, 10% lead, and 10% tin, is what gives the CuPb10Sn10 bimetallic bearing its exceptional tribological properties. The copper provides strength and thermal conductivity, the lead offers self-lubrication and conformability, and the tin enhances the alloy's overall hardness and wear resistance.

The Science Behind the Alloy: CuPb10Sn10 Composition

The CuPb10Sn10 alloy is a carefully engineered material designed to optimize bearing performance. The high copper content (80%) serves as the primary matrix, providing strength and excellent thermal conductivity. This ensures that the bearing can handle high loads while efficiently dissipating heat generated during operation.

The lead component (10%) is crucial for the bearing's self-lubricating properties. Lead has a low shear strength and tends to smear under pressure, creating a thin lubricating film on the bearing surface. This characteristic significantly reduces friction and wear, especially in boundary lubrication conditions where traditional lubricants might fail.

Tin (10%) plays a vital role in improving the alloy's overall hardness and corrosion resistance. It also enhances the bonding between the copper and lead, ensuring a homogeneous alloy structure that can withstand the rigors of industrial applications.

Manufacturing Process: Sintering and Extrusion

The production of CuPb10Sn10 bimetallic bearings involves a sophisticated manufacturing process that ensures optimal bonding between the steel backing and the copper alloy lining. The process typically involves the following steps:

- Preparation of the steel backing

- Application of the copper-lead-tin powder mixture

- Initial sintering to create a porous structure

- Secondary sintering to improve bonding and densification

- Secondary extrusion to enhance mechanical properties and surface finish

This multi-step process results in a bearing with excellent bonding strength between the steel backing and the copper alloy lining. The secondary sintering and extrusion steps are particularly crucial as they optimize the load-bearing capacity and ensure a uniform distribution of the alloy components.

Performance Characteristics of CuPb10Sn10 Bimetallic Bearings

Superior Load Capacity and Wear Resistance

One of the standout features of CuPb10Sn10 bimetallic bearings is their exceptional load-bearing capacity. The steel backing provides the necessary structural support, while the copper-lead-tin alloy lining offers excellent conformability and wear resistance. These bearings can handle loads up to 140 MPa, making them suitable for heavy-duty industrial applications.

The wear resistance of CuPb10Sn10 bimetallic bearings is equally impressive. The self-lubricating properties of the lead component, combined with the hardness provided by the copper and tin, result in minimal wear even under challenging operating conditions. This translates to extended service life and reduced maintenance requirements, ultimately leading to lower operational costs.

Thermal Management and Operating Temperature Range

Effective thermal management is crucial for bearing performance and longevity. CuPb10Sn10 bimetallic bearings excel in this aspect, thanks to the high thermal conductivity of copper. The copper content in the alloy lining efficiently dissipates heat, preventing localized hot spots and ensuring uniform temperature distribution across the bearing surface.

These bearings are designed to operate effectively across a wide temperature range, from -40°C to 150°C. This broad operating range makes them suitable for various industrial environments, from cold storage facilities to high-temperature processing plants.

Friction Reduction and Energy Efficiency

The inherent lubricity of the lead component in CuPb10Sn10 bimetallic bearings contributes significantly to friction reduction. Even in boundary lubrication conditions, where traditional lubricants might fail, these bearings maintain a low coefficient of friction. This characteristic not only enhances the overall efficiency of machinery but also leads to reduced energy consumption.

The energy efficiency gains from using CuPb10Sn10 bimetallic bearings can be substantial, especially in large-scale industrial operations. Lower friction translates to less power required to overcome resistance, resulting in reduced energy costs and a smaller carbon footprint.

Applications and Industries Benefiting from CuPb10Sn10 Bimetallic Bearings

Heavy Machinery and Construction Equipment

The construction and heavy machinery sectors are prime beneficiaries of CuPb10Sn10 bimetallic bearings. These bearings find applications in various components of excavators, bulldozers, and cranes. The high load capacity and wear resistance of CuPb10Sn10 bearings make them ideal for the pivot points of boom arms, bucket attachments, and hydraulic cylinders.

In these applications, the bearings are often subjected to extreme loads, shock impacts, and contamination from dirt and debris. The robust nature of CuPb10Sn10 bimetallic bearings, coupled with their self-lubricating properties, ensures reliable performance even in these harsh conditions. This translates to reduced downtime and maintenance costs for construction companies and heavy machinery operators.

Automotive and Transportation

The automotive industry has embraced CuPb10Sn10 bimetallic bearings for various applications, particularly in heavy-duty vehicles and commercial transport. These bearings are commonly used in engine components such as connecting rods, camshafts, and crankshafts. The superior load capacity and wear resistance of CuPb10Sn10 bearings contribute to improved engine performance and longevity.

In the realm of public transportation, CuPb10Sn10 bimetallic bearings play a crucial role in ensuring the smooth operation of buses and trains. They are used in wheel bearings, suspension systems, and door mechanisms, where their low friction characteristics and durability contribute to improved fuel efficiency and reduced maintenance intervals.

Industrial Manufacturing and Processing

The industrial manufacturing sector relies heavily on CuPb10Sn10 bimetallic bearings for various applications. In metalworking machinery, these bearings are used in the spindles of lathes, milling machines, and grinding equipment. Their ability to handle high loads and maintain precision under continuous operation makes them invaluable in ensuring product quality and production efficiency.

In the processing industry, CuPb10Sn10 bimetallic bearings find applications in pumps, compressors, and conveyor systems. The bearings' resistance to corrosion and ability to operate in a wide temperature range make them suitable for use in chemical processing plants, food production facilities, and pharmaceutical manufacturing units.

Marine and Offshore Applications

The marine industry presents unique challenges for bearing materials, with exposure to saltwater and varying temperatures being primary concerns. CuPb10Sn10 bimetallic bearings have proven their worth in this sector, finding applications in propeller shafts, rudder systems, and deck machinery.

The corrosion resistance of the copper-lead-tin alloy, combined with its excellent load-bearing capacity, makes these bearings ideal for use in marine environments. Their ability to operate effectively even with minimal lubrication is particularly valuable in underwater applications where regular maintenance is challenging.

Conclusion

CuPb10Sn10 bimetallic bearings represent a significant advancement in bearing technology, offering a unique combination of high load capacity, excellent wear resistance, and superior thermal management. Their versatility and performance characteristics make them an ideal choice for a wide range of industrial applications, from heavy machinery to precision manufacturing equipment.

As industries continue to seek ways to improve efficiency, reduce maintenance costs, and enhance the longevity of their machinery, CuPb10Sn10 bimetallic bearings are poised to play an increasingly important role. Their ability to operate effectively in challenging environments, coupled with their energy-efficient properties, aligns perfectly with the growing emphasis on sustainable and cost-effective industrial practices.

For businesses looking to optimize their operations and stay ahead in today's competitive landscape, considering the implementation of CuPb10Sn10 bimetallic bearings could be a game-changing decision. To learn more about how these innovative bearings can benefit your specific industry or application, don't hesitate to reach out to the experts at Wingold Bearing. Contact us at info@wingold.cc for personalized advice and solutions tailored to your needs.

FAQ

What makes CuPb10Sn10 bimetallic bearings unique?

CuPb10Sn10 bimetallic bearings combine a steel backing with a copper-lead-tin alloy lining, offering high load capacity, excellent wear resistance, and superior thermal management.

In which industries are CuPb10Sn10 bimetallic bearings commonly used?

These bearings are widely used in heavy machinery, automotive, industrial manufacturing, and marine applications.

What are the key benefits of using CuPb10Sn10 bimetallic bearings?

The main benefits include high load capacity, excellent wear resistance, efficient thermal management, and reduced friction, leading to improved energy efficiency and longer service life.

How do CuPb10Sn10 bimetallic bearings contribute to energy efficiency?

The self-lubricating properties and low friction characteristics of these bearings reduce energy consumption in machinery, leading to cost savings and a smaller carbon footprint.